Welding temperature field control system and method

A welding temperature and field control technology, applied in temperature control, control/regulation systems, welding equipment, etc., can solve problems such as difficulty in welding penetration consistency, achieve convenient detection and quality control, eliminate residual errors, and respond quickly. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

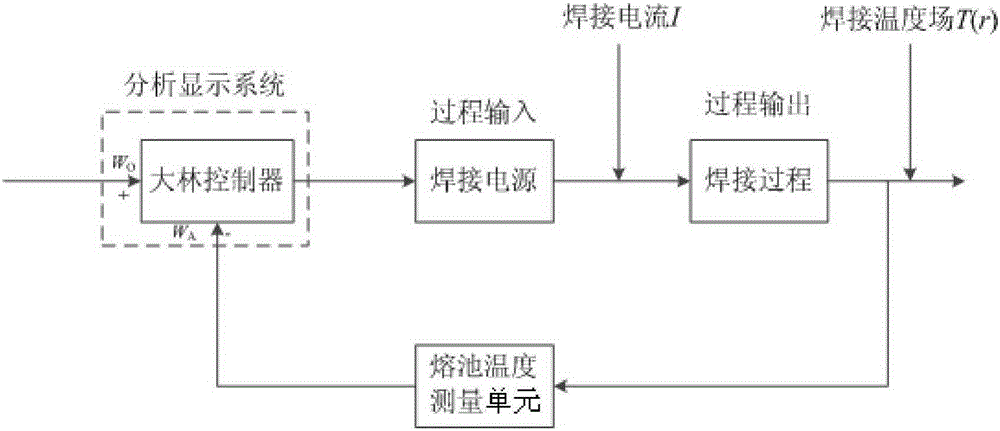

[0043] Such as figure 1 As shown, a welding temperature field control system of the present invention includes a welding machine system, a molten pool temperature measuring unit and a Dalin controller, wherein the output end of the Dalin controller is connected to the welding power supply of the welding machine system, and the molten pool temperature measuring unit will detect The molten pool data is sent to the acquisition signal input terminal of the Dalin controller. (This paragraph is related to figure 1 The text in is not very corresponding and should be treated uniformly)

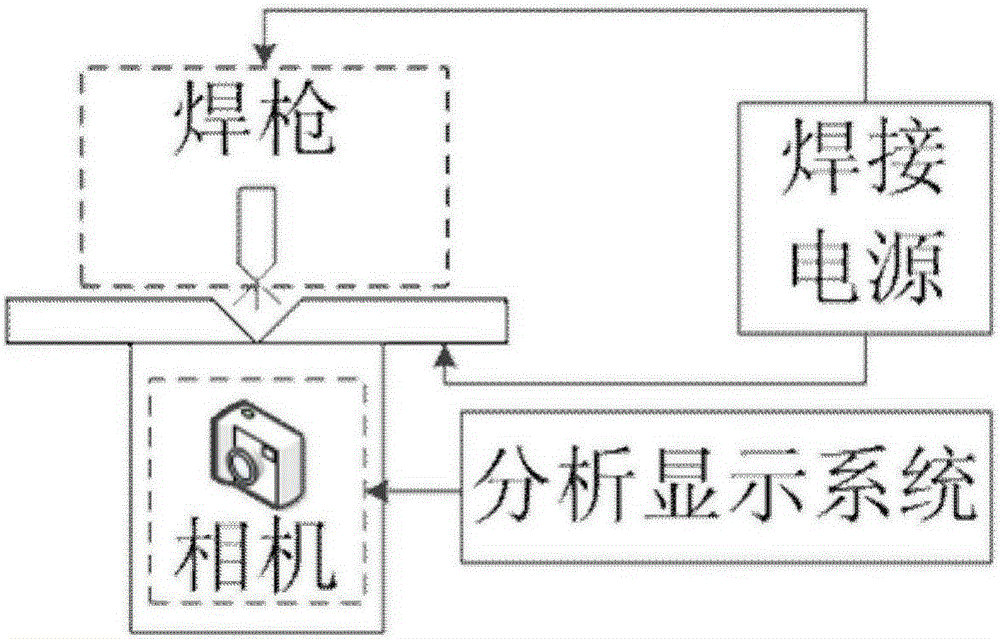

[0044] Such as figure 2 As shown, the molten pool temperature measurement unit includes a CCD camera, a data acquisition card, and an analysis display device, wherein the CCD camera is installed directly under the back of the weld to capture images of the weld pool and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com