Preparation method of adsorbent for purifying hydrogen sulfide, hydrogen phosphide and arsenic hydride simultaneously

An adsorbent and phosphine technology, applied in chemical instruments and methods, separation methods, other chemical processes, etc., can solve the problems of large-pore adsorbent preparation methods that have not been reported, achieve high selective adsorption performance, and be easy to use Effects of regeneration and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

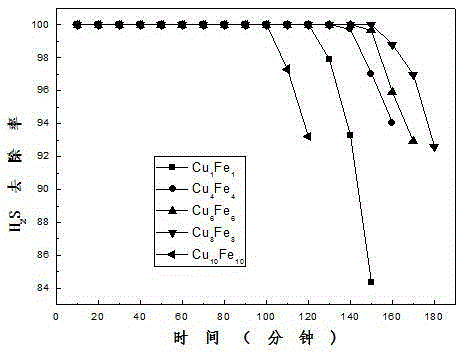

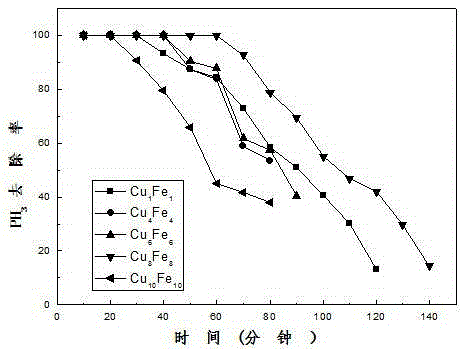

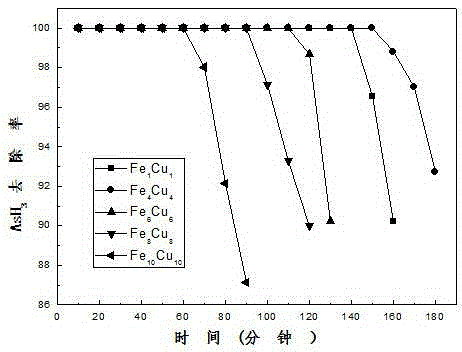

Image

Examples

Embodiment 1

[0029] (1) Dissolve concentrated sulfuric acid in distilled water at a ratio of 1mol / 1000ml, and stir until evenly mixed;

[0030](2) Add P123 to the solution in step (1) at a ratio of 5g / 100ml, and stir at 30°C for 60 minutes until the surfactant is completely dissolved;

[0031] (3) Add trimethylbenzene to the solution obtained in step (2) at a ratio of 1g / 100ml, and then add the solution obtained in step (2) to the mixed solution with a volume ratio of 10:1 to ethyl orthosilicate tetraethyl orthosilicate and stirred at 30°C for 6 hours;

[0032] (4) Pour the mixed solution obtained in step (3) into the reaction kettle, crystallize at 100°C for 72 hours, then wash the obtained powder with distilled water and filter until the test paper does not change color;

[0033] (5) Dry the solid substance obtained in step (4) at 150°C for 60 hours, and finally place the obtained white powder in a roasting furnace, raise the temperature to 600°C at 5°C / min for 2 hours, and cool natural...

Embodiment 2

[0038] (1) Dissolve concentrated hydrochloric acid in distilled water at a ratio of 2mol / 1000ml, and stir until evenly mixed;

[0039] (2) Add P123 to the solution in step (1) at a ratio of 15g / 100ml, and stir at 35°C for 20 minutes until the surfactant is completely dissolved;

[0040] (3) Add xylene to the solution obtained in step (2) at a ratio of 2g / 100ml, and then add orthosilicon to the mixed solution at a volume ratio of 14:1 between the solution obtained in step (2) and tetraethyl orthosilicate ethyl acetate and stirred at 35°C for 5 hours;

[0041] (4) Pour the mixed solution obtained in step (3) into the reaction kettle, crystallize at 110°C for 68 hours, then wash the obtained powder with distilled water and filter until the test paper does not change color;

[0042] (5) Dry the solid substance obtained in step (4) at 120°C for 12 hours, and finally place the obtained white powder in a roasting furnace, raise the temperature to 500°C at 4°C / min for 3 hours, and co...

Embodiment 3

[0047] (1) Dissolve concentrated nitric acid in distilled water at a ratio of 3mol / 1000ml, and stir until evenly mixed;

[0048] (2) Add F127 to the solution in step (1) at a ratio of 20g / 100ml, and stir at 40°C for 30 minutes until the surfactant is completely dissolved;

[0049] (3) Add ethylenediamine to the solution obtained in step (2) at a ratio of 3g / 100ml, and then add ortho Ethyl silicate and stirred at 40°C for 4 hours;

[0050] (4) Pour the mixed solution obtained in step (3) into the reaction kettle, crystallize at 120°C for 50 hours, then wash the obtained powder with distilled water and filter until the test paper does not change color;

[0051] (5) Dry the solid substance obtained in step (4) at 100°C for 30 hours, and finally place the obtained white powder in a roasting furnace, raise the temperature to 550°C at a rate of 3°C / min for 4 hours, and cool naturally to room temperature to obtain Adsorbent carrier;

[0052] (6) Add the dried adsorbent carrier in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com