Oil-in-water type emulsion preparing method and application of oil-in-water type emulsion in organic waste gas treatment

An oil-in-water type, organic waste gas technology, applied in chemical instruments and methods, use of liquid separation agents, separation of dispersed particles, etc., can solve the problem of the late start of research and application of organic waste gas purification technology, hindering the implementation of industrial VOCs treatment plans, precious metals The catalyst is expensive and other problems, and the preparation and use are simple and safe, the raw material source is convenient, and the price is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

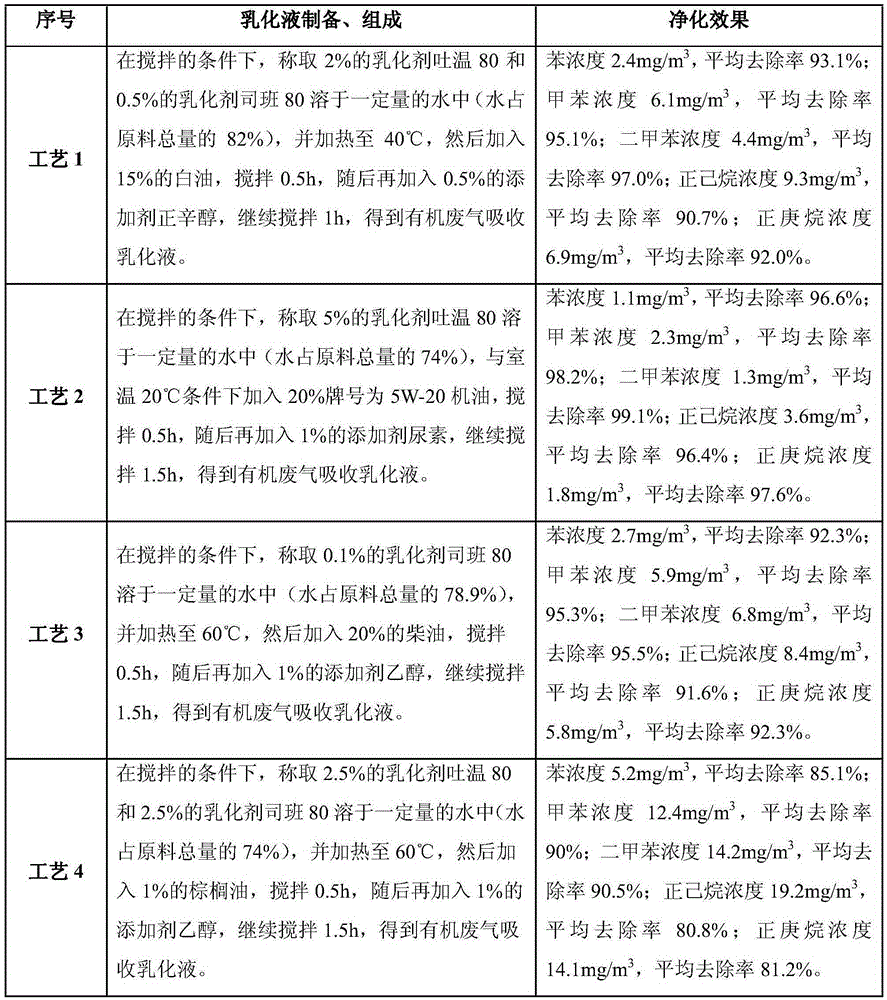

Examples

Embodiment 1

[0027] Organic waste gas from a spraying factory with an air volume of 5000m 3 / h, the exhaust gas temperature is 45°C, the main component is benzene 20-50mg / m 3 , with an average concentration of 35mg / m 3 ;Toluene 100-150mg / m 3 , with an average concentration of 125mg / m 3 ;The concentration of xylene is 100~200mg / m 3 , with an average concentration of 150mg / m 3 ;The concentration of n-hexane is 50-150mg / m 3 , with an average concentration of 100mg / m 3 ;The concentration of n-heptane is 50-100mg / m 3 , with an average concentration of 75mg / m 3 .

[0028] The above-mentioned sprayed organic waste gas is treated by the liquid absorption method, and the absorption tower adopts a packed tower. First, the emulsion is pumped by the circulating water pump to the top of the absorption tower, atomized and sprayed down, and at the same time, the organic waste gas enters from the bottom of the absorption tower through the deflector and high-speed swirling flow, running from botto...

Embodiment 2

[0034] A furniture factory emits organic waste gas with an air volume of 4000m 3 / h, the exhaust gas temperature is 45°C, the main component is n-hexane and the concentration is 50-150mg / m 3 , with an average concentration of 100mg / m 3 ;The concentration of ethyl acetate is 100-200mg / m 3 , with an average concentration of 125mg / m 3 , the concentration of butyl acetate is 100-200mg / m 3 , with an average concentration of 127mg / m 3 .

[0035] The above-mentioned furniture organic waste gas is treated by liquid absorption method, and the absorption tower adopts a packed tower. First, the emulsion is pumped by the circulating water pump to the top of the absorption tower, atomized and sprayed down, and at the same time, the organic waste gas enters from the bottom of the absorption tower through the deflector and high-speed swirling flow, running from bottom to top, the organic waste gas and the emulsion are absorbed Countercurrent contact in the tower, pollutants such as n-h...

Embodiment 3

[0041] A circuit board factory discharges organic waste gas with an air volume of 5000m 3 / h, the exhaust gas temperature is 40°C, the main component is toluene and the concentration is 50-130mg / m 3 , with an average concentration of 85mg / m 3 ;The concentration of butyl acetate is 50-120mg / m 3 , with an average concentration of 74mg / m 3 ; The concentration of xylene is 60-120mg / m 3 , with an average concentration of 76mg / m 3 .

[0042] The liquid absorption method is used to treat the organic waste gas of the above-mentioned circuit board factory, and the absorption tower adopts a packed tower. First, the emulsion is pumped by the circulating water pump to the top of the absorption tower, atomized and sprayed down, and at the same time, the organic waste gas enters from the bottom of the absorption tower through the deflector and high-speed swirling flow, running from bottom to top, the organic waste gas and the emulsion are absorbed Countercurrent contact in the tower, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com