A method for preparing copper-indium-gallium-sulfur solar cell thin film material after electrodeposition by bipotential step method

A technology of solar cells and copper indium gallium sulfide, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as hindering the conversion efficiency of solar cells, difficulty in providing cathode overpotential, and small electrochemical stability window, and achieve large-area The effects of high-quality film preparation, improvement of microscopic characteristics such as composition and morphology, and avoidance of adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

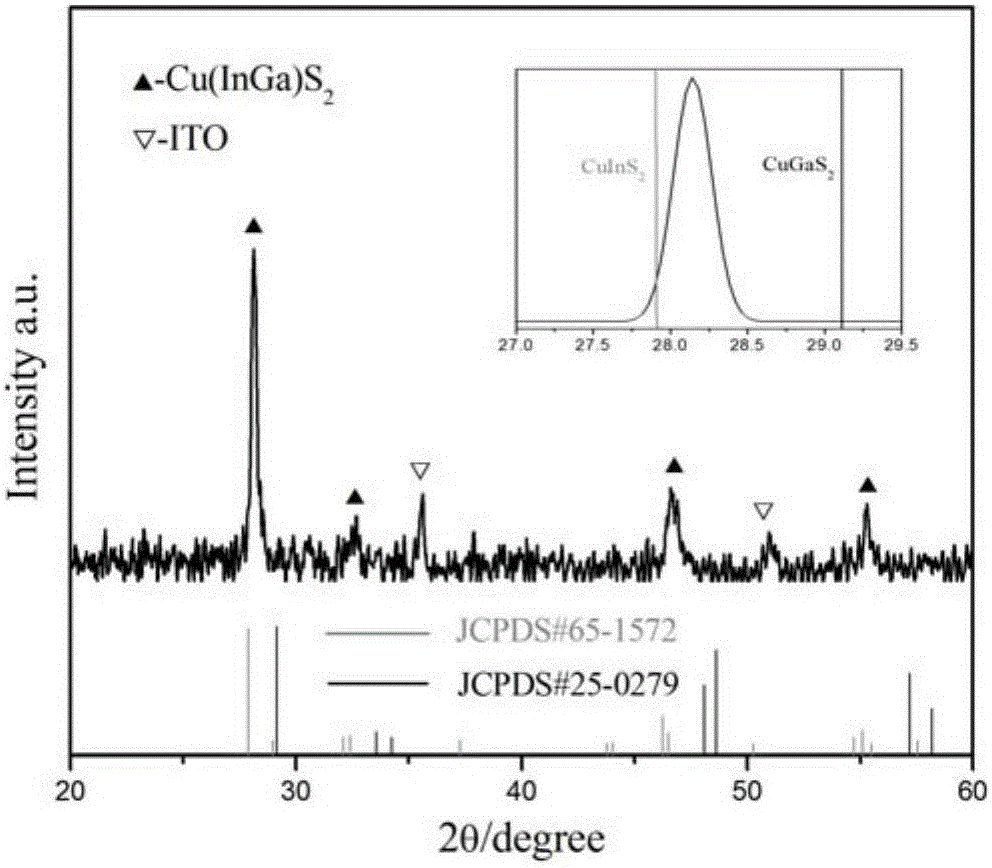

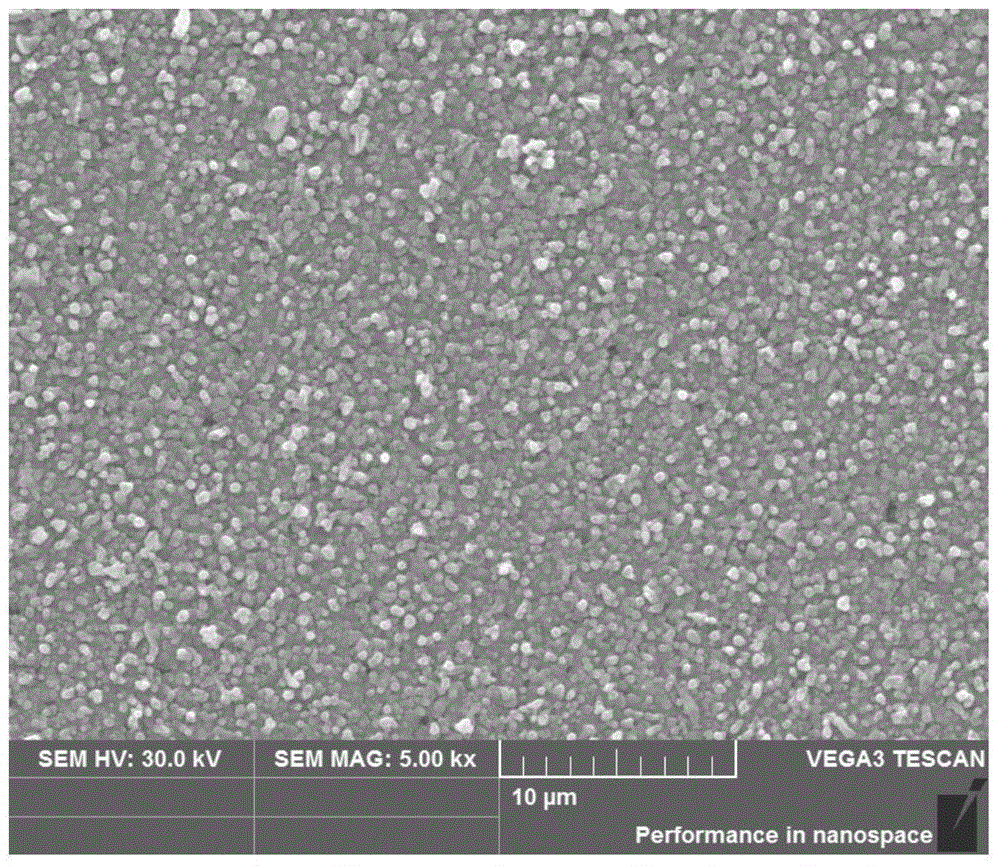

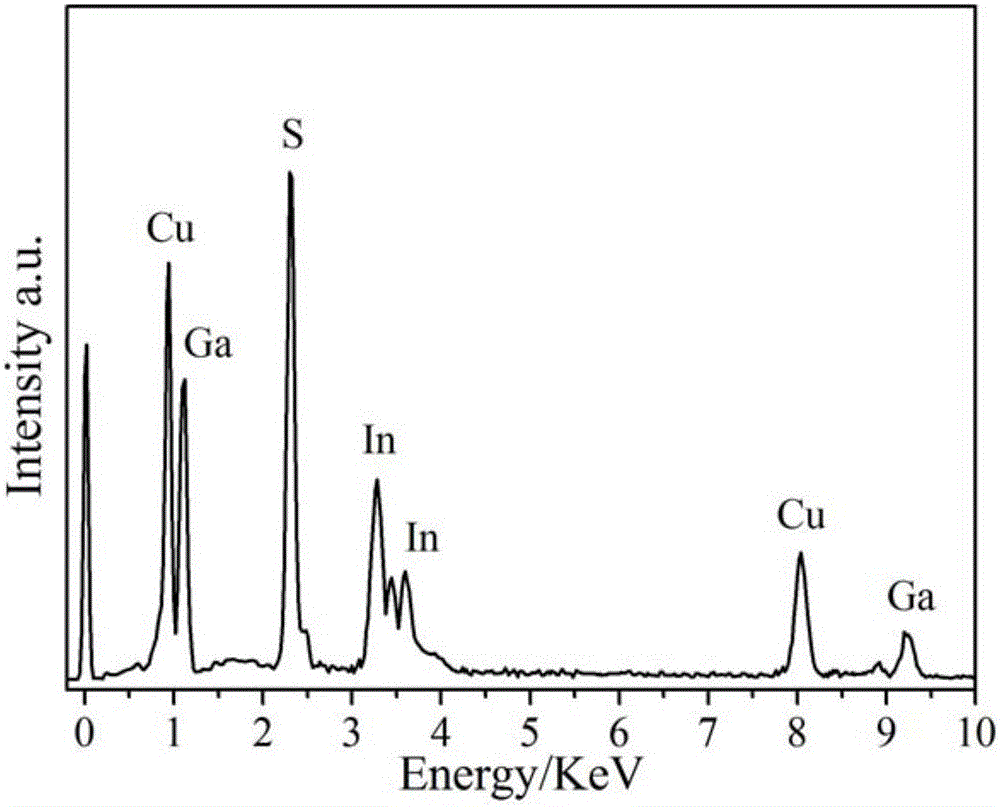

[0032] A method for preparing a copper indium gallium sulfur solar cell thin film material after electrodeposition by a bipotential step method and followed by sulfuration annealing, the preparation steps are as follows:

[0033] (1) Mix choline chloride and urea in a molar ratio of 1:2, stir evenly and place in a vacuum oven at 80°C for 10 hours to prepare 40ml of colorless and transparent ionic liquid;

[0034] (2) Dissolving 30mM cupric chloride in the ionic liquid, stirring it to fully dissolve;

[0035] (3) Add 60mM gallium chloride again, stir to make it fully dissolve;

[0036] (4) Use acetone, ethanol and deionized water successively to ultrasonically clean the ITO conductive glass for 10 minutes, and then dry the ITO conductive glass with high-purity nitrogen;

[0037](5) With the ITO conductive glass substrate cleaned in step (4) as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum wire as the counter electrode, with...

Embodiment 2

[0045] A method for preparing a copper indium gallium sulfur solar cell thin film material after electrodeposition by a bipotential step method and followed by sulfuration annealing, the preparation steps are as follows:

[0046] (1) Mix choline chloride and urea in a molar ratio of 1:2, stir evenly and place in a vacuum oven at 80°C for 10 hours to prepare 40ml of colorless and transparent ionic liquid;

[0047] (2) Dissolving 40mM cupric chloride in the ionic liquid, stirring it to fully dissolve;

[0048] (3) Add 75mM gallium chloride again, stir to make it fully dissolve;

[0049] (4) Use acetone, ethanol and deionized water successively to ultrasonically clean the ITO conductive glass for 30 minutes, then dry the ITO conductive glass with high-purity nitrogen;

[0050] (5) With the ITO conductive glass substrate cleaned in step (4) as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum wire as the counter electrode, with -0...

Embodiment 3

[0053] A method for preparing a copper indium gallium sulfur solar cell thin film material after electrodeposition by a bipotential step method and followed by sulfuration annealing, the preparation steps are as follows:

[0054] (1) Mix choline chloride and urea in a molar ratio of 1:2, stir evenly and place in a vacuum oven at 80°C for 10 hours to prepare 40ml of colorless and transparent ionic liquid;

[0055] (2) Dissolving 30mM cupric chloride in the ionic liquid, stirring it to fully dissolve;

[0056] (3) Add 65mM gallium chloride again, stir to make it fully dissolve;

[0057] (4) Use acetone, ethanol and deionized water successively to ultrasonically clean the ITO conductive glass for 20 minutes, and then dry the ITO conductive glass with high-purity nitrogen;

[0058] (5) With the ITO conductive glass substrate cleaned in step (4) as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum wire as the counter electrode, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com