Heat pump water heating system with function of divided-flow reinforced heat recovery

A heat pump hot water, split-flow technology, applied in heat pumps, fluid heaters, refrigeration and liquefaction, etc., can solve the problems of poor adaptability of two-stage heat exchange site, leakage of refrigerant in disassembly and handling, and restrictions on popularization and application, to ensure The effect of water safety, reduced installation difficulty and maintenance rate, and high thermal energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

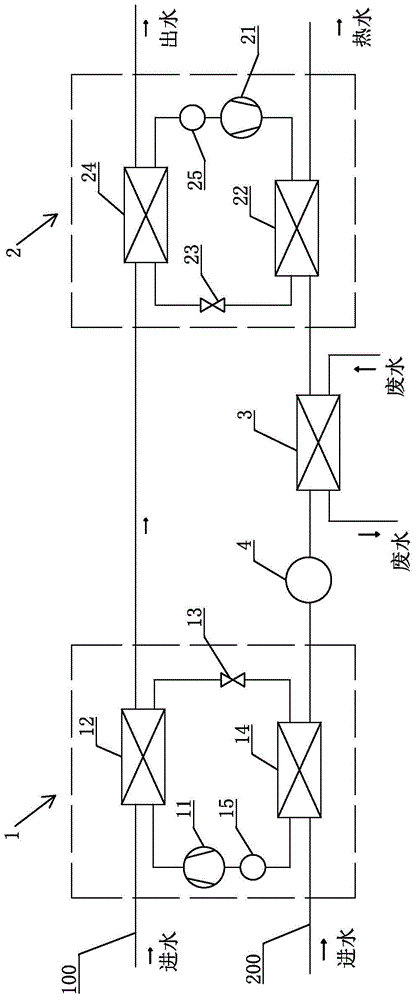

[0012] refer to figure 1 , the heat pump hot water system with split-flow enhanced heat recovery of the present invention includes a first heat pump device 1, a second heat pump device 2, a heating device 3 for heating water flow, a first water inlet flow path 100 and a second water inlet flow path 200 , the first heat pump device 1 includes a first compressor 11, a first condenser 12, a first throttling device 13 and a first evaporator 14 forming a circulation loop, and the second heat pump device 2 includes a circulation loop The second compressor 21, the second condenser 22, the second throttling device 23 and the second evaporator 24, the first water inlet flow path 100 passes through the first condenser 12 and the second evaporator 24, the second water inlet flow path 200 Via the first evaporator 14 , the heating device 3 and the second condenser 22 , the heating device 3 is arranged between the first evaporator 14 and the second condenser 22 . In order to ensure the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com