Secondary electro-optic crystal with gradient refractive index effect as well as preparation method and application method of secondary electro-optic crystal

A gradient refractive index and secondary electro-optic technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

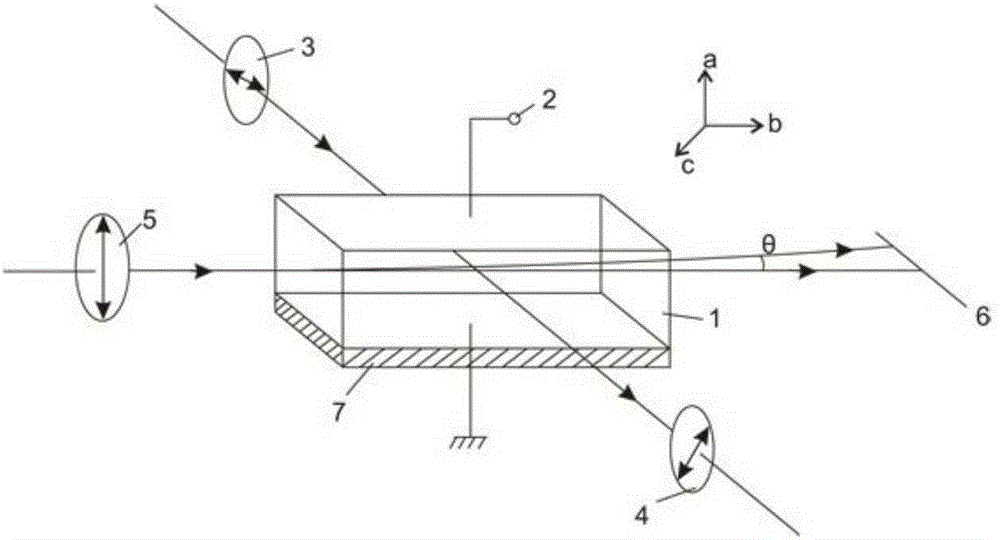

Image

Examples

Embodiment 1

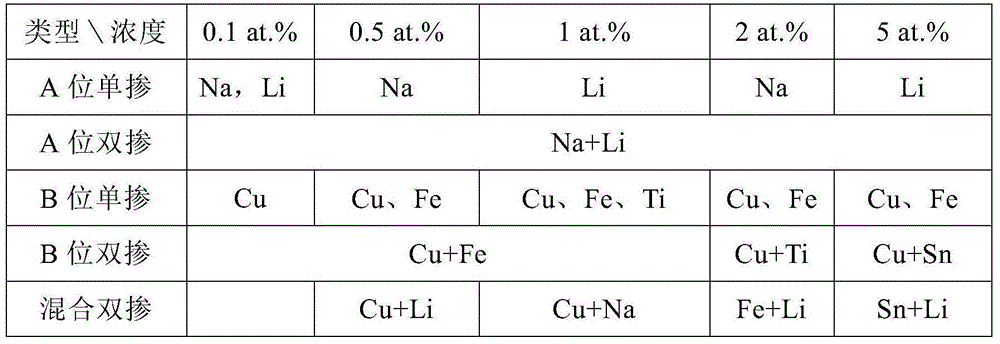

[0041] Example 1: Cu:KTa 0.67 Nb 0.33 o 3 (Cu doping amount 0.25at%)

[0042] high purity K 2 CO 3 、 Ta 2 o 5 , Nb 2 o 5 According to the molar ratio K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 =1.25:0.34:0.66 Weigh the ingredients, press CuO:(Ta 2 o 5 +Nb 2 o 5 ) / 2=0.25:100 molar ratio to calculate the weight of doped ion CuO powder, and mix it uniformly, put it into a platinum crucible after briquetting, and sinter in a muffle furnace at 1075°C for more than 24 hours to obtain Cu:KTN polycrystalline material About 1000 grams, put the Cu:KTN polycrystalline material in a platinum crucible, and carry out crystal growth in the atmosphere. After the process of seeding, necking, shouldering, and equal diameter growth, block Cu:KTa is obtained. 0.67 Nb 0.33 o 3 crystals.

[0043] Present embodiment gained Cu:KTa 0.67 Nb 0.33 o 3 crystal, the matrix component Ta / Nb is uniformly distributed in the crystal, and the doped ion Cu 2+ Inside the crystal, the distribution is li...

Embodiment 2

[0044] Example 2: Cu:KTa 0.63 Nb 0.37 o 3 (Cu doping amount 0.5at%)

[0045] The crystal growth preparation process of this example is basically similar to Example 1, the difference is that the ratio of raw materials is adjusted to K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 =1.25:0.31:0.69, the total mass of polycrystalline material is about 1000 grams, CuO:(Ta 2 o 5 +Nb 2 o 5 ) / 2 Weighing at a molar ratio of 0.25:100, the synthesis and sintering temperature of the polycrystalline material was adjusted to 1025° C., and the crystal growth process was the same as in Example 1. The resulting Cu:KTa 0.63 Nb 0.37 o 3 Cu in crystal 2+ It is distributed linearly and decreasingly along the c-axis direction, the ion concentration gradient is about 0.15at% / cm, and the corresponding crystal refractive index gradient is about 4×10 -3 / mm.

Embodiment 3

[0046] Embodiment 3: Fe:KTa 0.61 Nb 0.39 o 3 (Fe doping amount 1at%)

[0047] The crystal growth preparation process of this example is basically the same as that of Example 1, the difference is that the ratio of raw materials is adjusted to K 2 CO 3 : Ta 2 o 5 :Nb 2 o 5 =1.2:0.29:0.71, doped ion iron oxide according to Fe 2 o 3 :( 2 o 5 +Nb 2 o 5 ) was weighed at a molar ratio of 1:100, the synthesis and sintering temperature of the polycrystalline material was adjusted to 1000° C., and the crystal growth process was the same as in Example 1. Obtained Fe:KTa 0.63 Nb 0.37 o 3 Fe in crystal 3+ It is distributed linearly and decreasingly along the c-axis direction, the ion concentration gradient is about 0.3at% / cm, and the corresponding crystal refractive index gradient is about 3×10 -3 / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com