A kind of manufacturing method of the rotary cutting device of high viscosity polymer gel

A technology of a rotary cutting device and a manufacturing method, which is applied in the field of building materials engineering, and can solve the problem of not being able to better meet the needs of disintegrating high-viscosity polymer gels, cutting polymer gels that cannot be flexibly networked, and not being able to achieve crushed gels Fully uniform dispersion and other issues, to achieve good adjustability, optimized shearing function and stirring function, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

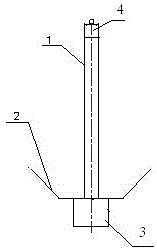

[0025] (1) Make the connecting rod 1, the first concave blade 2, the second concave blade 3 and the electric driver 4; the connecting rod 1 is a solid metal circular straight rod, and the upper end of the connecting rod 1 is a hexagonal column with an outer diameter of 8 mm and a length of b is 350mm; the specifications of the first concave blade 2 and the second concave blade 3 are the same, the expanded length is 120mm, the width is 20mm, and the thickness is 1.5mm, and the first concave blade 2 is bent upward from the center 1 / 2, The bending angles are all 45°, and the second concave blade 3 is bent downward from 1 / 2 of the center, the bending angles are all 45°, and both are symmetrically concave.

[0026] (2) The first concave blade 2 and the second concave blade 3 are cross-welded to form a stacked concave blade; the lower end of the connecting rod 1 is fixed to the center of the first concave blade 2 and the second concave blade 3 by threads.

[0027] (3) The hexagonal ...

Embodiment 2

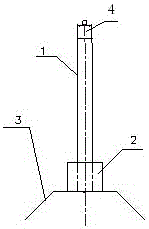

[0031] (1) Make the connecting rod 1, the first concave blade 2, the second concave blade 3 and the electric driver 4; the connecting rod 1 is a solid metal circular straight rod, and the upper end of the connecting rod 1 is a hexagonal column with an outer diameter of 10 mm and a length of It is 4350mm; the specifications of the first concave blade 2 and the second concave blade 3 are the same, the expanded length is 150mm, the width is 20mm, and the thickness is 1.5mm, and the first concave blade 2 and the second concave blade 3 are 1 / 2 downward bends, the bending angles are both 45°, and both are symmetrically concave.

[0032] (2) The first concave blade 2 and the second concave blade 3 are cross-welded to form a stacked concave blade; the lower end of the connecting rod 1 is fixed to the center of the first concave blade 2 and the second concave blade 3 by threads.

[0033] (3) The hexagonal column at the upper end of the connecting rod 1 is fastened to the electric driv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com