Leather with electromagnetic shielding performance and preparing method thereof

An electromagnetic shielding and leather technology, applied in the field of natural leather preparation, can solve the problem of high hardness, achieve the effect of improving conductivity, improving shielding and ensuring conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing leather (sheep) with electromagnetic shielding properties:

[0030] A. Take sheep leather, add 4g / m 2 Polymethyl methacrylate (PMMA) on the leather surface area is evenly sprayed on the leather surface and dried;

[0031] B. Add 18g / m 2 The nano-silver-coated copper powder (particle size 40-800nm) on the surface of the leather is dispersed in ethanol and ultrasonically dispersed for 30 minutes to obtain a dispersion;

[0032] C. Press the product obtained in step A for 4 seconds at 8MPa and 70°C, then evenly spray the dispersion obtained in step B and dry it;

[0033] D. Spray evenly a layer of 7g / m on the surface of the product obtained in step C 2 The PMMA of the leather surface area is dried to obtain leather with electromagnetic shielding properties.

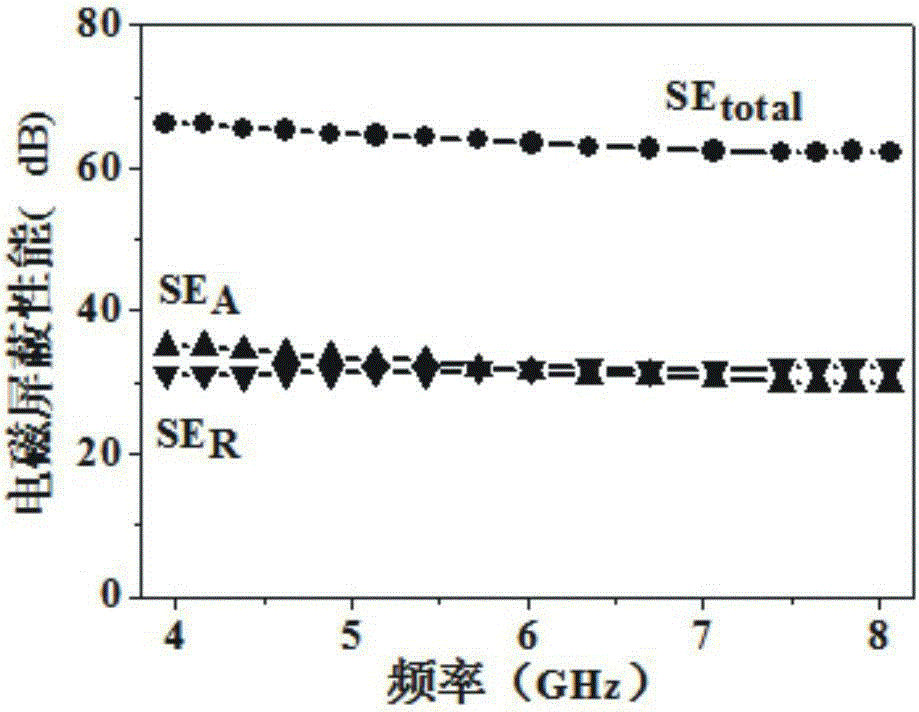

[0034] tested as figure 1 As shown, the surface conductivity of the leather with electromagnetic shielding performance of the present embodiment is 1.21×10 5 S / m, the total electromagnetic...

Embodiment 2

[0036] A preparation method of leather (buffalo) with electromagnetic shielding properties:

[0037] A. Take buffalo leather, add 2g / m 2 The PMMA of leather surface area is evenly sprayed on this leather surface, dry;

[0038] B. Add 10g / m 2 Nano metal copper powder (particle size 50-600nm) on the leather surface area is dispersed in acetone, and ultrasonically dispersed for 60 minutes to obtain a dispersion;

[0039] C. Press the product obtained in step A at 2MPa and 40°C for 2s, then evenly spray the dispersion obtained in step B and dry it;

[0040] D. Evenly spray a layer of 3g / m on the surface of the product obtained in step C 2 Polyurethane (PU) of leather surface area, dry, is natural leather with electromagnetic shielding properties.

[0041] tested as figure 2 As shown, the surface conductivity of this electromagnetic shielding natural leather is 2.81×10 3 S / m, SE in the frequency range of 0.5-3GHz total over 48dB, where SE A Up to 30dB, SE R Up to 20dB; te...

Embodiment 3

[0043] A method for preparing leather (cow) with electromagnetic shielding properties:

[0044] A. Take the cow leather, add 6g / m 2 The PU of the leather surface area is evenly sprayed on the leather surface and dried;

[0045] B. Add 16g / m 2 Nano ferric oxide powder (particle size 200-700nm) on the surface of the leather is dispersed in deionized water and ultrasonically dispersed for 90 minutes to obtain a dispersion;

[0046] C. Press the product obtained in step A for 25 seconds at 4MPa and 60°C, then evenly spray the dispersion obtained in step B and dry it;

[0047] D. Evenly spray a layer of 5g / m on the surface of the product obtained in step C 2 Amino tetrafunctional epoxy resin (EP) on the surface area of the leather is dried to obtain leather with electromagnetic shielding properties.

[0048] tested as image 3 As shown, the surface conductivity of this electromagnetic shielding leather is 3.72×10 4 S / m, SE in the frequency range of C-band (4-8GHz) total ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface conductivity | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Surface conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com