A device and method for continuously synthesizing polypropylene carbonate polyols

A polypropylene carbonate and polyol technology, applied in the chemical industry, can solve the problems of low gas-liquid two-phase mass transfer rate, incapable of continuous production, low utilization rate of raw materials, etc., so as to improve the utilization rate of CO2, reduce the consumption of raw materials, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

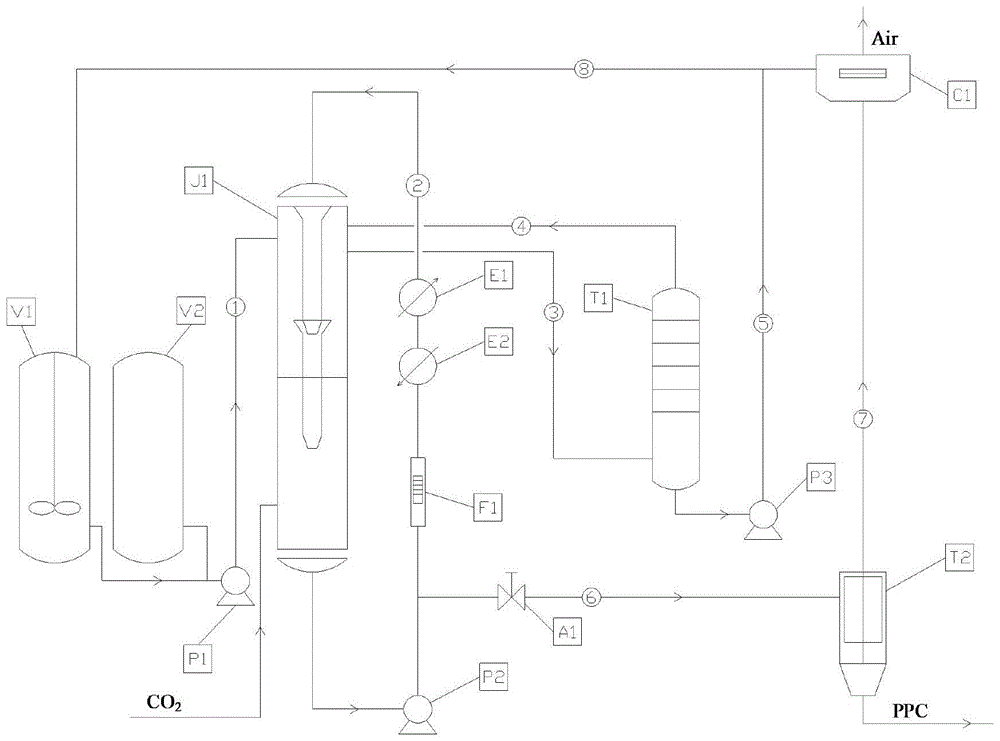

[0043] The present embodiment provides a kind of device of continuous synthesis polypropylene carbonate polyol, such as figure 1 As shown, the device comprises a dual-stage jet reactor J1 and a scraped thin film evaporator T2;

[0044] Wherein, the upper part of the two-stage jet reactor J1 is provided with liquid-phase material inlets respectively connected to the propylene oxide and catalyst storage tank V1 and the molecular weight regulator storage tank V2, and the bottom is provided with a gas-phase raw material inlet;

[0045] The two-stage jet reactor J1 is also provided with an exhaust port on the upper part and a liquid phase product output port on the bottom. The exhaust port is connected to the gas-liquid separator T1 through a gas delivery pipeline, and the liquid phase product output port is connected through a pipeline. To the feed port of the scraped film evaporator T2; the bottom of the scraped film evaporator T2 is connected to the polypropylene carbonate polyo...

Embodiment 2

[0050] This embodiment provides a method for continuously synthesizing polypropylene carbonate polyols using the device described in Example 1. The synthesis process of polypropylene carbonate polyols is as follows figure 1 Shown:

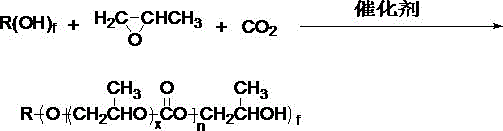

[0051] (1) Mix propylene oxide (PO) with catalyst, store in propylene oxide and catalyst storage tank V1, and keep stirring; add molecular weight regulator R(OH) f Stored in Molecular Weight Regulator Storage Tank V2. After starting up, the two storage tanks output raw materials at a certain ratio, and are sent to the dual-stage jet reactor J1 from the top by the delivery pump P1 through the pipeline 1. CO 2 The gas is passed into the dual-stage jet reactor J1 from the bottom.

[0052] (2) After a certain amount of raw materials are accumulated in the dual-stage jet reactor J1, the circulation pump P2 is turned on, and the mixed material is sent to the dual-stage jet reactor J1 from the top through the pipeline 2 to form a circulation. At this ...

Embodiment 3

[0057] This embodiment provides a method for continuously synthesizing polypropylene carbonate polyols using the device described in Embodiment 1. Compared with Embodiment 2, the only difference is: in this embodiment, the dual-stage jet reactor is high 16m, inner diameter 0.8m. Molecular weight regulator is glycerol, the mass dosage ratio of propylene oxide and catalyst is 1000:1; The molar dosage ratio of propylene oxide and molecular weight regulator is 8:1; CO 2 The molar dosage is 1 / 4 of that of propylene oxide, the reaction temperature is 60°C, the residence time is 4h, and the yield is 91%. Compared with loop reactors of the same scale, the reaction energy consumption is reduced by 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com