Preparation method of polyurethane curing agent

A technology of polyurethane curing agent and curing agent, which is applied in the preparation of polyurethane curing agent and toluene diisocyanate polyurethane curing agent. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

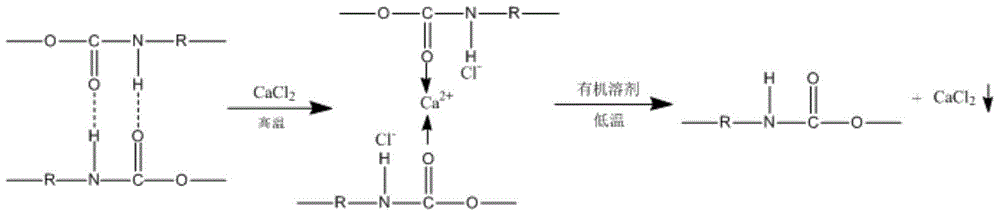

Method used

Image

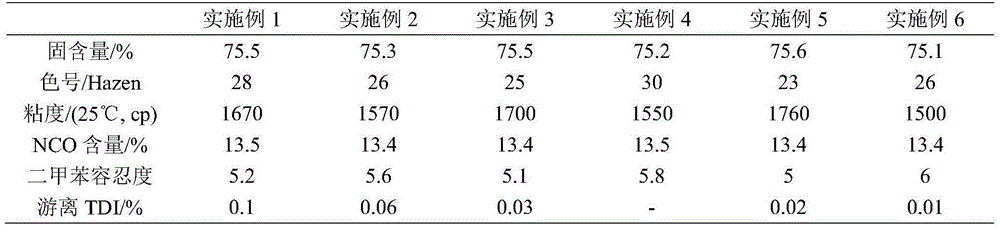

Examples

Embodiment 1

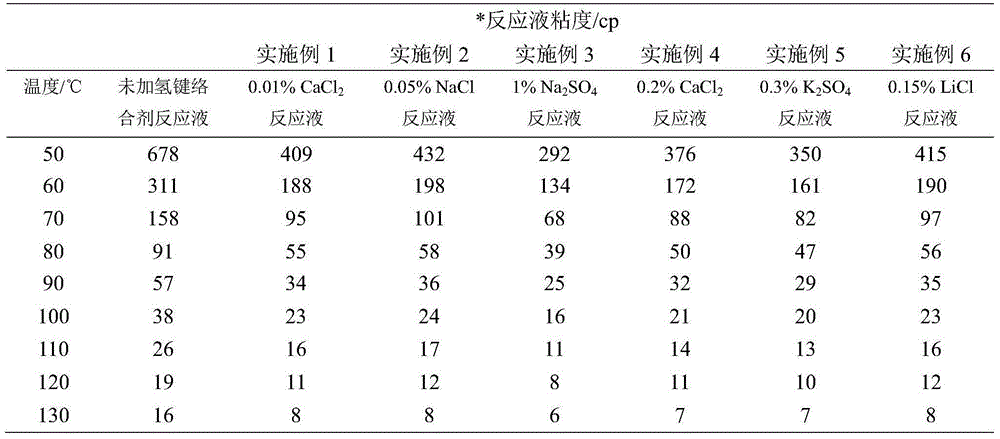

[0046] 1kg of diethylene glycol and 2.2kg of trimethylolpropane are used to form a mixed alcohol and heated at 70°C for stand-by; 2,6-TDI composition) into the reaction kettle, heated and stirred at 50°C, then added the mixed alcohol dropwise into the reaction kettle for 1 hour; after the dropwise addition, continued to stir and react at 50°C for 1 hour , the obtained polyurethane prepolymer reaction solution enters the polyurethane prepolymer tank at 60°C and keeps warm for use;

[0047] To the obtained polyurethane prepolymer reaction solution containing free toluene diisocyanate monomer, the temperature was raised to 100° C., 2 g of calcium chloride dehydrated at high temperature was added and stirred for 15 minutes, and then separated by a thin-film evaporator with a vacuum of 0.1 mbar. The separated prepolymer enters the dilution kettle and dilutes with ethyl acetate to obtain a product with a solid content of 75wt%. After the product is cooled to room temperature and the...

Embodiment 2

[0049] 700g of ethylene glycol and 1.5kg of trimethylolethane are used to form a mixed alcohol and heated and kept warm at 70°C for use; 2,6-TDI composition) into the reaction kettle, heated and stirred at 55°C, then added the mixed alcohol dropwise into the reaction kettle for 2 hours; after the dropwise addition, continued to stir and react at 55°C for 2 hours Finally, the resulting polyurethane prepolymer reaction solution enters the polyurethane prepolymer tank at 70°C and is kept warm for use;

[0050] The resulting polyurethane prepolymer reaction solution containing excess toluene diisocyanate monomer was heated up to 100°C, 10 g of sodium chloride dehydrated at high temperature was added and stirred for 15 minutes, and then separated by a thin film evaporator with a vacuum of 2 mbar. The separated prepolymer enters the diluting tank and dilutes with ethyl acetate to obtain a product with a solid content of 50wt%. After the product is cooled to room temperature and the ...

Embodiment 3

[0052] 1kg of 1,4-butanediol and 1kg of glycerol are used to form a mixed alcohol and heated at 70°C for use; under nitrogen protection, 20kg of toluene diisocyanate 70 / 30 (70wt% of 2,4-TDI and 30wt% of 2,6-TDI composition) into the reaction kettle, heated and stirred at 60°C, then added the mixed alcohol dropwise into the reaction kettle for 2 hours; , the resulting polyurethane prepolymer reaction liquid enters the polyurethane prepolymer tank at 70°C and keeps warm for use;

[0053] To the obtained polyurethane prepolymer reaction solution containing excess toluene diisocyanate monomer, the temperature was raised to 90° C., 200 g of sodium sulfate dehydrated at high temperature was added and stirred for 20 minutes, and then separated by a thin-film evaporator with a vacuum of 1 mbar. The separated prepolymer enters the diluting tank and dilutes with butyl acetate to obtain a product with a solid content of 80wt%. After the product is cooled to room temperature and the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com