Method for preparing carbon nano tube by means of cobalt chloride catalyst

A technology of cobalt chloride catalyst and carbon nanotubes, which is applied in the field of chemical reactions and can solve problems such as high raw material prices, complicated processes, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

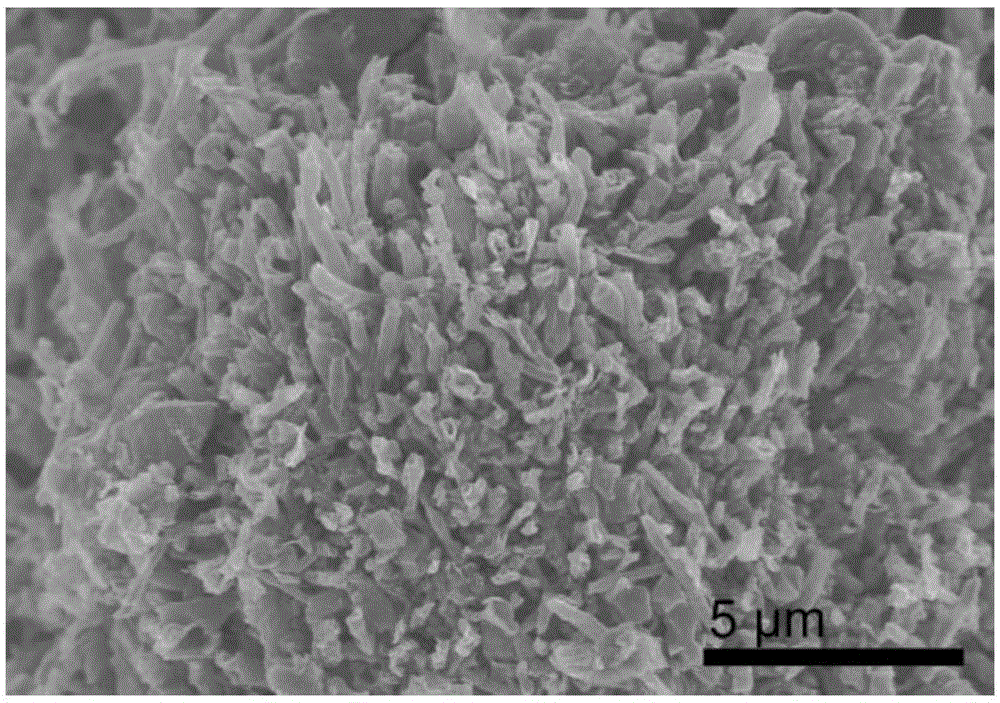

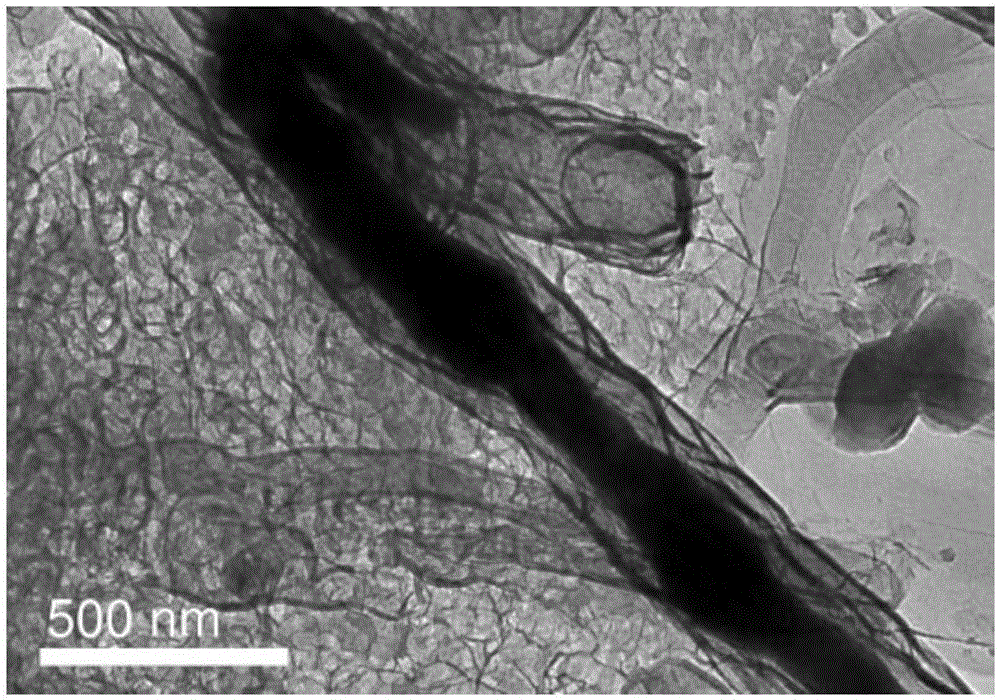

[0022] 3 grams of glucose, 3 grams of melamine, 3 grams of cobalt chloride and 5 milliliters of distilled water were mixed and ground into a uniform mixture, and the above mixture was dried at 80 degrees Celsius for 12 hours to obtain a pink solid; after the above pink solid was ground into a powder Transfer to the high-temperature tube furnace, heat up to 700 degrees Celsius in flowing nitrogen, and maintain 700 degrees Celsius for 4 hours to obtain a black solid; the above-mentioned black solid is cooled to room temperature, transferred to a glass beaker, and 50 milliliters of HCl is added with a content of 10 % (mass percent) hydrochloric acid solution, stirred and dissolved for 6 hours; after the above-mentioned solid matter washed with hydrochloric acid was suction-filtered with a microporous membrane, washed to neutrality with 2000 milliliters of distilled water, and then rinsed with 50 milliliters of acetone, The obtained solid matter was vacuum-dried at 50° C. for 10 ho...

Embodiment 2

[0024] 3 grams of glucose, 3 grams of melamine, 3 grams of cobalt chloride and 5 milliliters of distilled water were mixed and ground into a uniform mixture, and the above mixture was dried at 80 degrees Celsius for 12 hours to obtain a pink solid; after the above pink solid was ground into a powder Transfer to the high-temperature tube furnace, heat up to 750 degrees Celsius in flowing nitrogen, and maintain 750 degrees Celsius for 4 hours to obtain a black solid; the above-mentioned black solid substance is cooled to room temperature, transferred to a glass beaker, and 50 milliliters of HCl is added with a content of 10 % (mass percent) hydrochloric acid solution, stirred and dissolved for 6 hours; after the above-mentioned solid matter washed with hydrochloric acid was suction-filtered with a microporous membrane, washed to neutrality with 2000 milliliters of distilled water, and then rinsed with 50 milliliters of acetone, The obtained solid matter was vacuum-dried at 50° C....

Embodiment 3

[0026] 3 grams of glucose, 3 grams of melamine, 3 grams of cobalt chloride and 5 milliliters of distilled water were mixed and ground into a uniform mixture, and the above mixture was dried at 80 degrees Celsius for 12 hours to obtain a pink solid; after the above pink solid was ground into a powder Transfer to the high-temperature tube furnace, heat up to 800 degrees Celsius in flowing nitrogen, and maintain 800 degrees Celsius for 4 hours to obtain a black solid; the above-mentioned black solid is cooled to room temperature, transferred to a glass beaker, and 50 milliliters of HCl is added with a content of 10 % (mass percent) hydrochloric acid solution, stirred and dissolved for 6 hours; after the above-mentioned solid matter washed with hydrochloric acid was suction-filtered with a microporous membrane, washed to neutrality with 2000 milliliters of distilled water, and then rinsed with 50 milliliters of acetone, The obtained solid matter was vacuum-dried at 50° C. for 10 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com