Ultraviolet (UV) continuous printing device for transfusion bag film material

A printing device and infusion bag technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of insufficient cost advantages, low utilization rate of UV printing machines, and reduced printing speed and efficiency, so as to reduce printing costs, The effect of bright colors, improving printing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

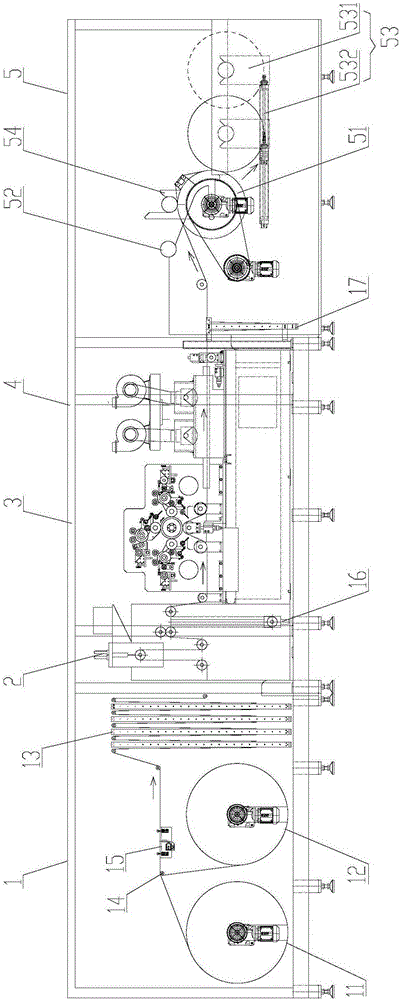

[0037] Please refer to figure 1 , figure 1 It is a structural schematic diagram of a specific embodiment of the UV continuous printing device for the film material of the transfusion bag provided by the present invention.

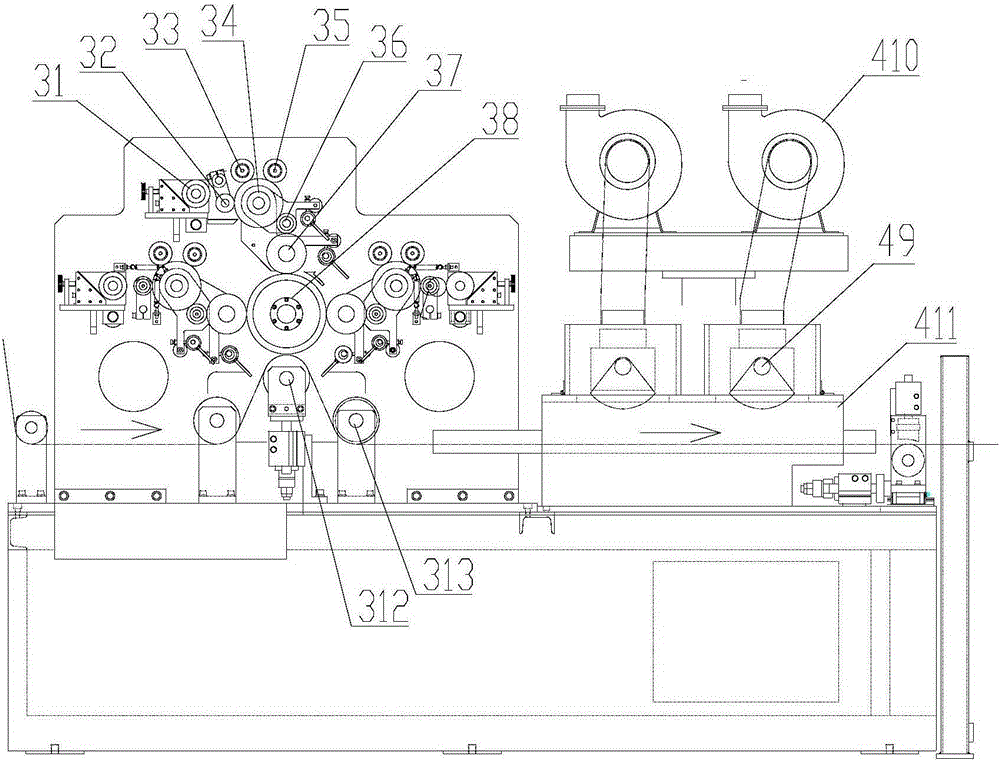

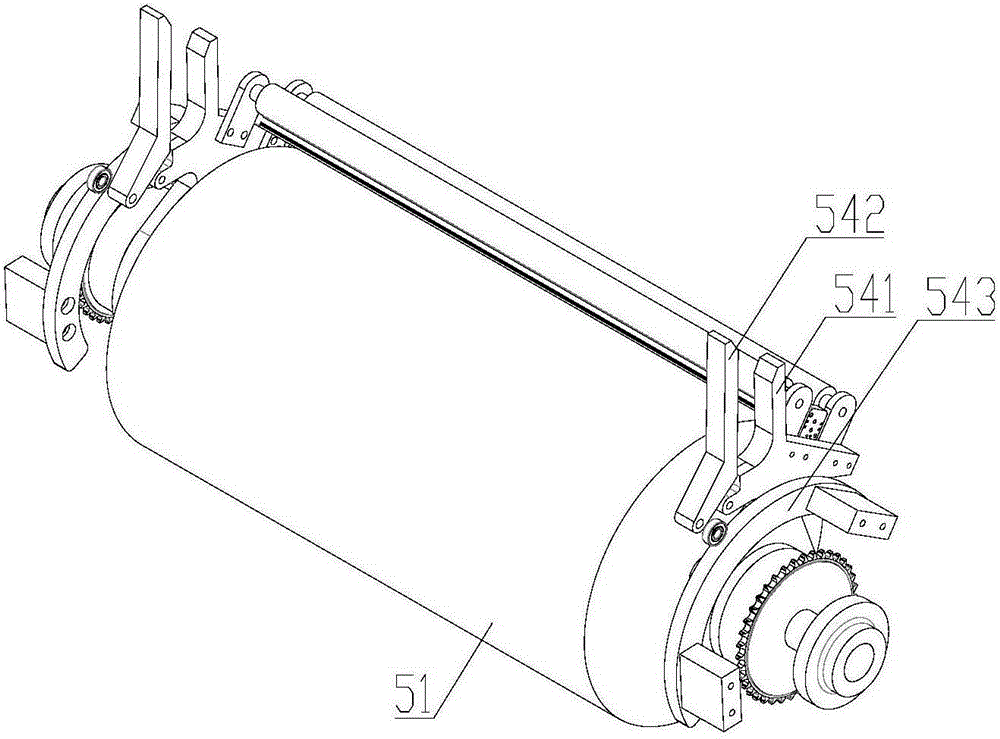

[0038] In a specific embodiment, the UV continuous printing device for infusion bag film material provided by the present invention mainly consists of an uninterrupted film supply device 1, a corona treatment device 2, a UV printing device 3, a UV The drying device 4 and the automatic continuous film wrapping device 5 constitute.

[0039] Among them, the uninterrupted film feeding device 1 is used to continuously output the film material to be printed to the subsequent device, and the automatic continuous film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com