Sand bath type capsule polishing and dedusting integrated machine

A sand bath type, all-in-one machine technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of uneven and incomplete polishing of capsules, affecting the hygienic quality of capsules, etc. Achieve the effect of saving handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

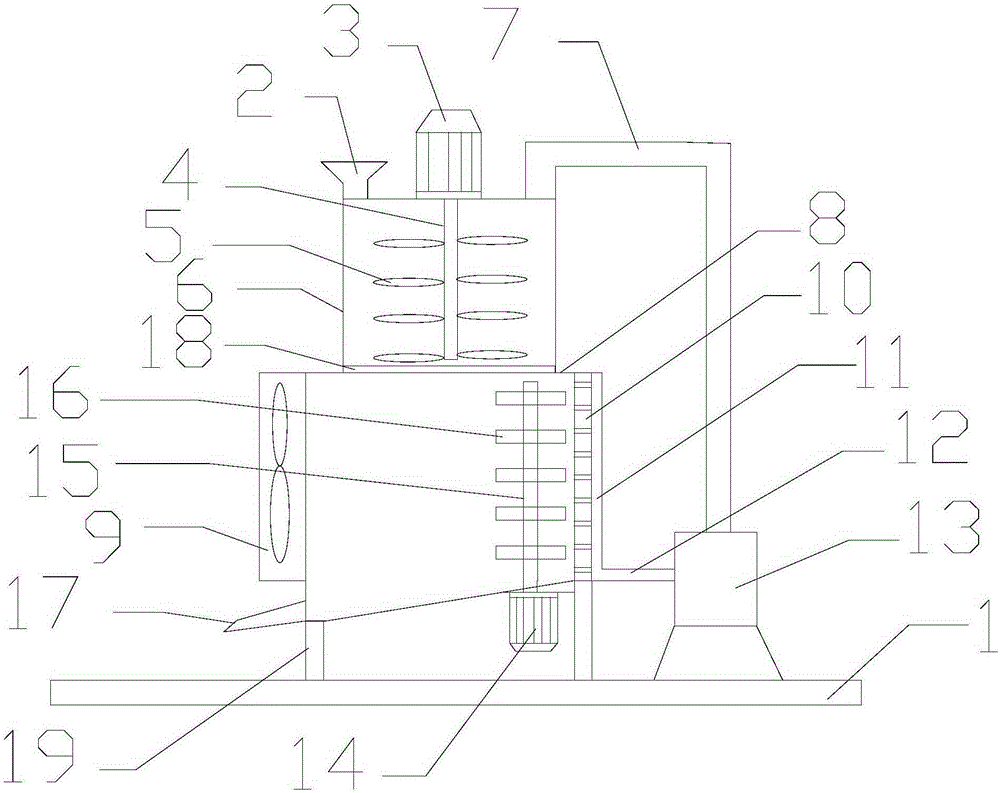

[0012] refer to figure 1 , a sand bath type capsule polishing and dust removal machine of the present invention, comprising a base 1, a hopper 2, a first motor 3, a first stirring shaft 4, a first stirring paddle 5, a sand bath box 6, and a sand inlet pipe 7 , dust removal box 8, ion fan 9, sand separation net 10, sand collection layer 11, sand discharge pipe 12, sand delivery pump 13, second stirring motor 14, second stirring shaft 15, second stirring paddle 16, discharge pipe 17. The first motor 3 is installed on the top of the sand bath box 6, and the first stirring shaft 4 is installed on the first motor 3, and the first stirring shaft 4 extends into the sand bath box 6. On the first stirring shaft 4, Several first stirring paddles 5 are installed, the shape of the sand bath box 6 is cylindrical, the top of the sand bath box 6 is fixed with a feed hopper 2, the bottom of the sand bath box 6 is a movable bottom plate 18, and the dust removal box 8 is installed on the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com