A kind of preparation method of lube oil base oil isomerization dewaxing catalyst

A technology of lubricating base oil and isomerization dewaxing, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve low pour point, high yield and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

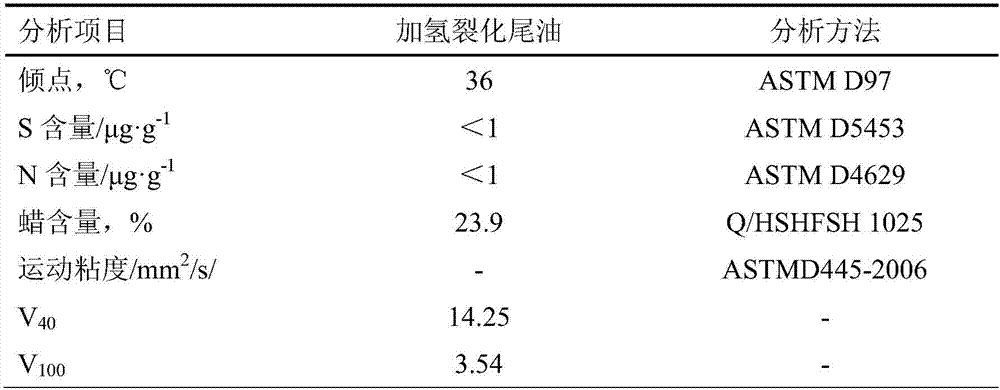

Examples

Embodiment 1

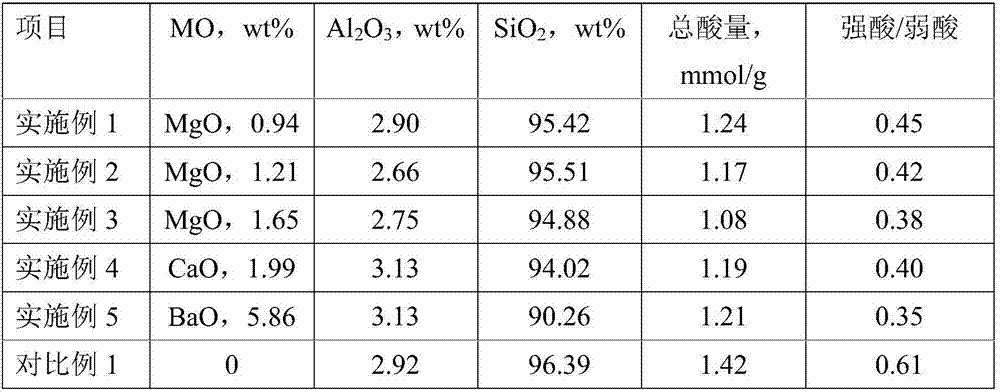

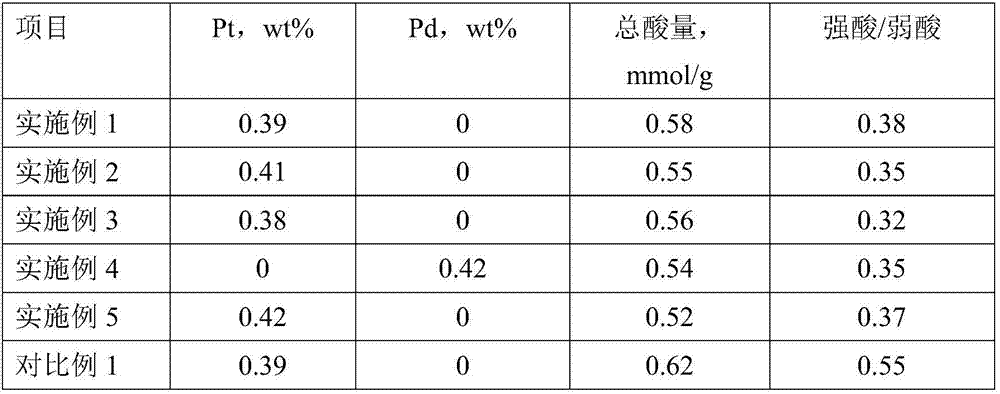

[0026] (1) Synthesis of Mg-ZSM-22 molecular sieve

[0027] 1) 25.8g of aluminum sulfate (17.2wt%Al 2 o 3 ), 8.65g of magnesium sulfate (MgO content 16.2wt%) were dissolved in 200g of water; 2) 1400mL of deionized water was added to a 5L autoclave, and 10.8g of NaOH was added to stir; 3) 518g of alkaline silica sol (30wt% SiO 2 ) into the reactor and continue to stir; 4) Add the 1) solution to the reactor and continue to stir; 5) Add 115g of ethylenediamine to the reactor and stir, then raise the temperature to 160°C for crystallization for 96 hours; 6) After washing and filtering , the filter cake was dried at 110°C for 10 h to obtain MgO / Na 2 O / Al 2 o 3 / SiO 2 Mg-ZSM-22 molecular sieve raw powder with a molar ratio of 0.82:0.42:1:55.9.

[0028] (2) Carrier molding

[0029] 1) 41.2g Mg-ZSM-22, 80g SB powder (dry basis 75wt%, Al 2 o 3 content>99%), mixed with 1.2g methyl cellulose; 2) configure 71g 5wt% dilute nitric acid solution; 3) knead 2) and 1) in a kneader for 4...

Embodiment 2

[0037] (1) Synthesis of Mg-ZSM-22 molecular sieve

[0038] 1) 25.8g of aluminum sulfate (17.2wt%Al 2 o 3 ), 12.98g of magnesium sulfate (MgO content 16.2wt%) were dissolved in 200g of water; 2) 1400mL of deionized water was added to a 5L autoclave, and 10.8g of NaOH was added to stir; 3) 518g of alkaline silica sol (30wt% SiO 2 ) into the reactor and continue to stir; 4) Add the 1) solution to the reactor and continue to stir; 5) Add 115g of ethylenediamine to the reactor and stir, then raise the temperature to 160°C for crystallization for 96 hours; 6) After washing and filtering , the filter cake was dried at 110°C for 10 h to obtain MgO / Na 2 O / Al 2 o 3 / SiO 2 Mg-ZSM-22 molecular sieve raw powder with a molar ratio of 1.15:0.39:1:61.

[0039] (2) Carrier molding

[0040] With embodiment 1 step (2).

[0041] (3) Carrier ammonia exchange

[0042] With embodiment 1 step (3)

[0043] (4) Alcohol-amine solution treatment

[0044]Dissolve 0.3g of dodecylamine in 100g of...

Embodiment 3

[0048] (1) Synthesis of Mg-ZSM-22 molecular sieve

[0049] 1) 25.8g of aluminum sulfate (17.2wt%Al 2 o 3 ), 16.23g of magnesium sulfate (MgO content 16.2wt%) were dissolved in 200g of water; 2) 1400mL of deionized water was added to a 5L autoclave, and 10.8g of NaOH was added to stir; 3) 518g of alkaline silica sol (30wt% SiO 2 ) into the reactor and continue to stir; 4) Add the 1) solution to the reactor and continue to stir; 5) Add 115g of ethylenediamine to the reactor and stir, then raise the temperature to 160°C for crystallization for 96 hours; 6) After washing and filtering , the filter cake was dried at 110°C for 10 h to obtain MgO / Na 2 O / Al 2 o 3 / SiO 2 Mg-ZSM-22 molecular sieve raw powder with a molar ratio of 1.52:0.43:1:58.6.

[0050] (2) Carrier molding

[0051] With embodiment 1 step (2).

[0052] (3) Carrier ammonia exchange

[0053] With embodiment 1 step (3)

[0054] (4) Alcohol-amine solution treatment

[0055] Dissolve 0.4g of hexadecylamine in 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com