Tungsten-oxide-quantum-dot-material simulated peroxidase

A technology of tungsten oxide quantum dots and peroxidase, applied in tungsten oxide/tungsten hydroxide, physical/chemical process catalyst, analysis by chemical reaction of materials, etc., can solve easy deactivation, purification difficulty, limitation application and other problems, to achieve the effect of good peroxidase activity, simple preparation process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 0.03g of tungsten sulfide, add 200mL of double-distilled water at 65°C, and sonicate in an ultrasonic cleaner (power 400W) for 15-24 hours (preferably 18 hours). Filter through a sand core funnel with a pore size of 0.22 μm to obtain a filter cake, and then resuspend the collected filter cake in 30 mL of twice distilled water. The above solution is placed in a polytetrafluoroethylene high-pressure reactor, reacted at 200°C for 12-18 hours (preferably 15 hours), and then cooled to room temperature to obtain a hydrothermal product. The obtained hydrothermal product is filtered through a sand core funnel with a pore size of 0.22 μm, and the filtrate is collected to obtain a tungsten oxide quantum dot material solution. After suspension steaming, ethanol dispersion, centrifugation (centrifuge speed is 16000r / min, time 30min), vacuum drying (temperature is 50°C-60°C (preferably 55°C), drying time is 8h-12h (preferably 10 hours) )) step to obtain tungsten oxide quantum...

Embodiment 2

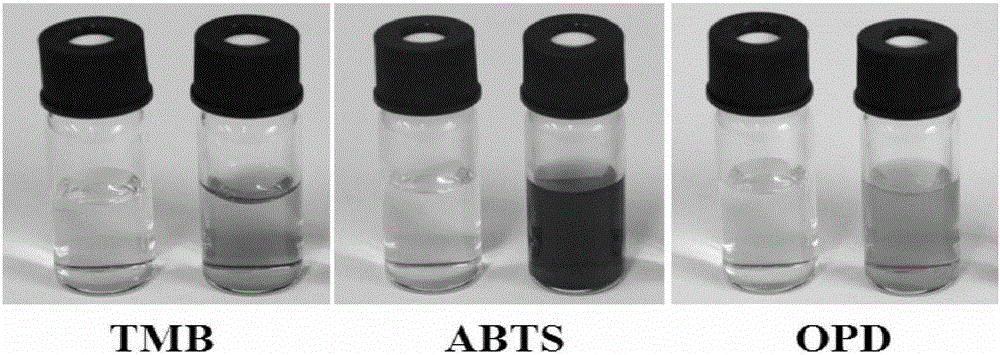

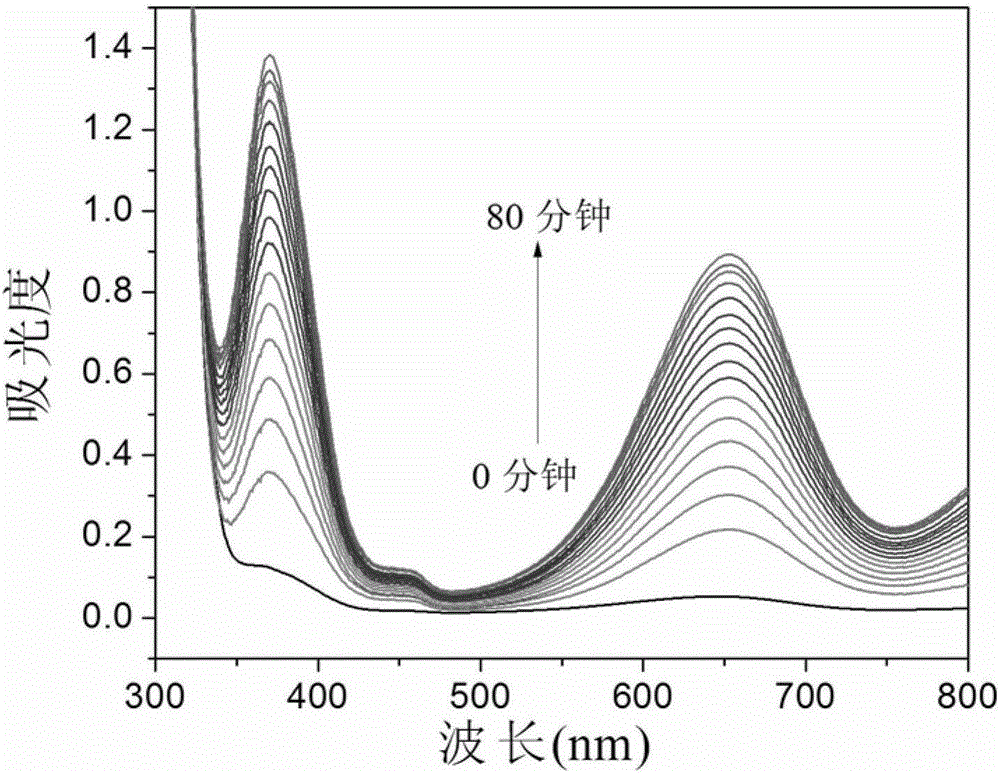

[0032] Add 0.2mL of 3% hydrogen peroxide and 0.2mL of 4mmol / L 3,3',5,5'-tetramethylbenzidine to 0.5mLHAc-NaAc buffer (pH3.6, 20mmol / L) Hydrochloric acid and 100 μL of the tungsten oxide quantum dot material aqueous solution prepared in Example 1 with a concentration of 10 μg / mL were mixed and incubated at 37°C for 30 minutes, and the solution changed from colorless to blue (see figure 1 , left), with an absorption peak at 652nm (see figure 2 ).

Embodiment 3

[0034] Add 0.2mL of 3% hydrogen peroxide and 0.2mL of 4mmol / L 2,2'-azino-bis(3-ethylbenzene And thiazoline-6-sulfonic acid) diammonium salt and 100 μ L concentration are the tungsten oxide quantum dot material aqueous solution that the embodiment 1 of 10 μ g / mL makes, after mixing, the solution changes from colorless to green immediately (see figure 1 , middle image).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com