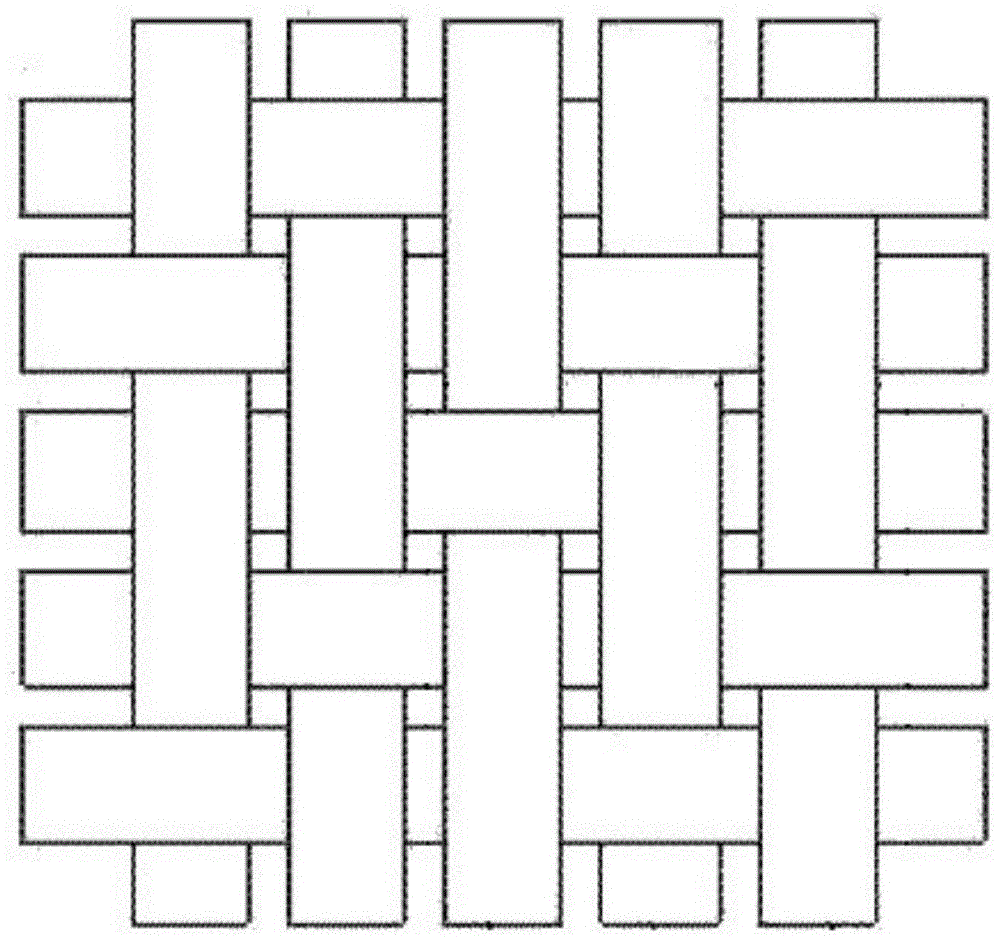

Waterproof and breathable anti-ultraviolet polypropylene yarn-dyed fabric

An anti-ultraviolet, waterproof and breathable technology, used in textiles, fabrics, textiles and papermaking, etc., can solve the problems of monotonous design, unable to meet the diverse needs of young people's fashion and leisure, lack of functionality, and environmental protection fabrics, etc. The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

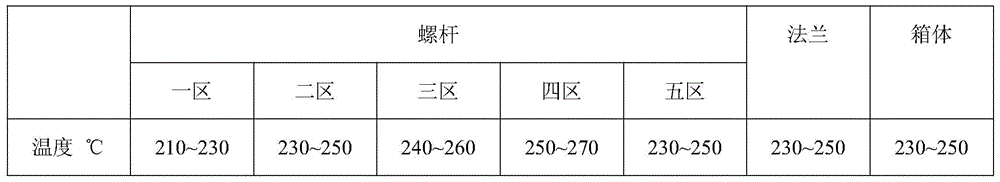

[0018] The polypropylene fiber material (produced in Jinan) whose brand is H30S is used as the raw material of isotactic polypropylene, its MFR value is 35g / 10min, and its isotactic index is greater than 94%. The content of styrene-maleic anhydride copolymer in the spinning material is 6.0wt%, the content of Et-MAH-acrylic resin is 3.6wt%, and the content of triallyl isocyanurate is 1.2wt%, The content of methyltriacetoxysilane is 0.6wt%, the content of color masterbatch is 1.6wt%, and the balance is isotactic polypropylene. The above raw materials were mechanically blended and then melt-spun and extruded. The range of spinning temperature is shown in Table 1.

[0019] Table 1

[0020]

[0021] The melt evenly flows into the spinning box and spins through the three-lobed spinneret hole of the spinneret, and the spinning speed is 2000 m / min. The number of holes on each spinneret is 48. The tow is oiled with an oil nozzle for cooling, and drawn by a hot roller. The tempera...

Embodiment 2

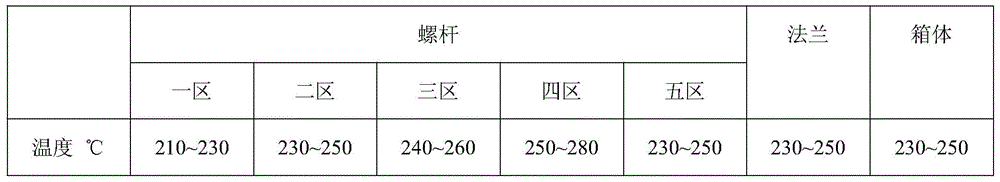

[0025] The polypropylene fiber material (produced in Jinan) whose brand is H30S is used as the raw material of isotactic polypropylene, its MFR value is 35g / 10min, and its isotactic index is greater than 94%. The content of styrene-maleic anhydride copolymer in the spinning stock is 7.0wt%, the content of Et-MAH-acrylic resin is 4.2wt%, and the content of triallyl isocyanurate is 1.4wt%, The content of methyltriacetoxysilane is 0.7wt%, the content of color masterbatch is 1.7wt%, and the balance is isotactic polypropylene. The above raw materials were mechanically blended and then melt-spun and extruded. The range of spinning temperature is shown in Table 3.

[0026] table 3

[0027]

[0028] The melt evenly flows into the spinning box and spins through the three-lobed spinneret hole of the spinneret, and the spinning speed is 2000 m / min. The number of holes on each spinneret is 100. The tow is oiled with oil nozzles for cooling, and drawn by three hot rollers. The temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| isotactic index | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com