An etchant and etching method for displaying solidified dendrite structure of medium and high-grade non-oriented silicon steel

A technology of oriented silicon steel and dendritic structure, applied in the field of metallographic inspection and analysis, can solve the problems of dendritic morphology damage, secondary dendrite damage, long corrosion time, etc. Simple operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

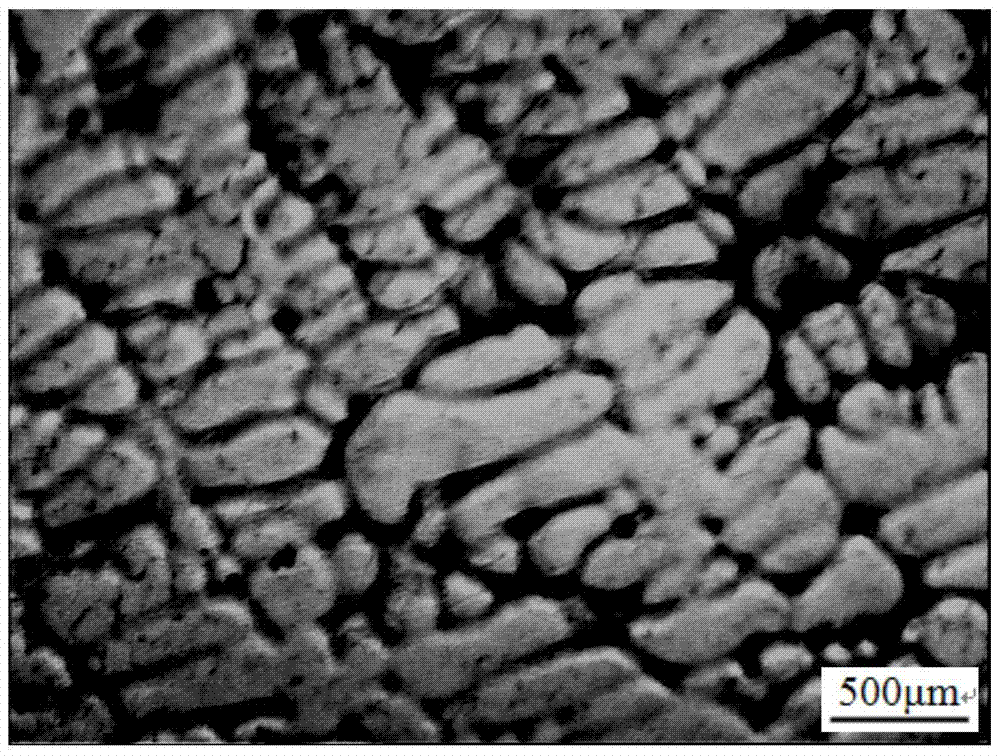

[0017] The chemical composition of 50W600 non-oriented silicon steel is shown in Table 1. Grind the solidified samples of 50W600 non-oriented silicon steel on 150#, 400#, 600#, 1000#, 2000# water sandpaper in sequence, and then polish with 2.5μm diamond grinding paste on a polishing machine until the surface of the sample is smooth as a mirror surface. Obvious scratches. After polishing, rinse the surface with alcohol, and then dry it with a polishing machine to prepare for erosion. Add 1.5g of analytically pure (purity ≥99.8%) picric acid sealed in water into a beaker containing 35ml of distilled water, and then add 0.4ml of hydrochloric acid, 0.3g of copper chloride and 0.5g of sodium dodecylbenzene sulfonate in sequence, Stir well. Heat the prepared etching solution on the heating furnace until the etching solution boils, and then use tweezers to clamp the processed sample so that the polishing surface is facing down, and suspend it in the etching solution in the beaker. A...

Embodiment 2

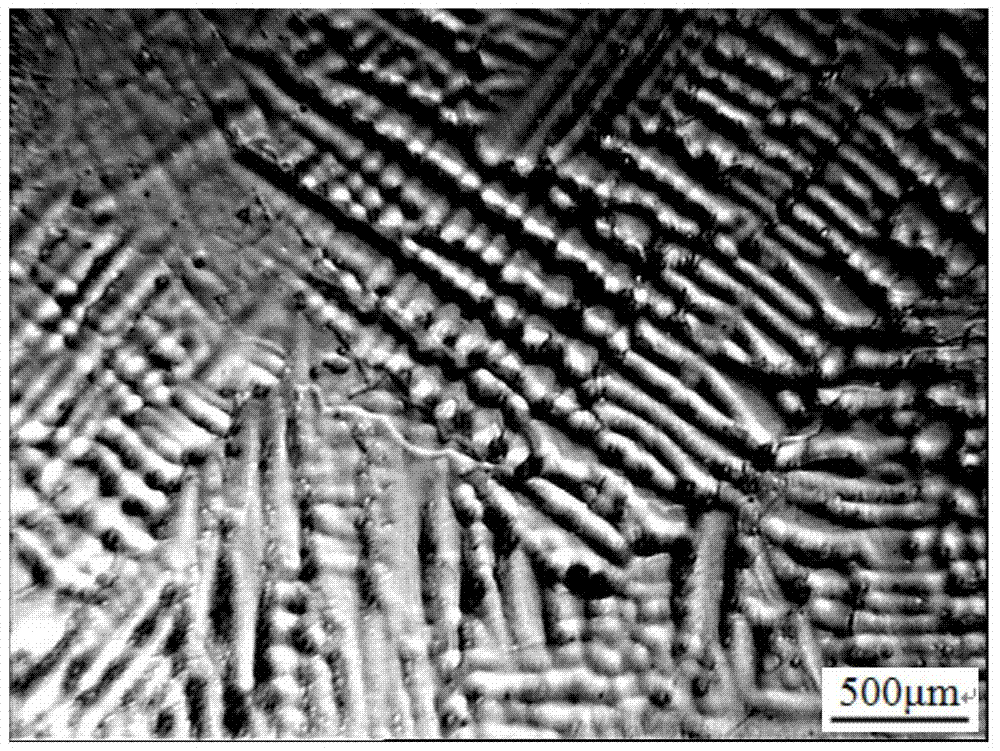

[0021] The chemical composition of 50W310 non-oriented silicon steel is shown in Table 2. Grind the solidified samples of 50W310 non-oriented silicon steel on 150#, 400#, 600#, 1000#, 2000# water sandpaper in sequence, and then polish with 2.5μm diamond abrasive paste on the polishing machine until the surface of the sample is smooth as a mirror surface. Obvious scratches. After polishing, rinse the surface with alcohol, and then dry it with a polishing machine to prepare for erosion. Add the water-sealed 2.0 analytically pure (purity ≥99.8%) picric acid into a beaker containing 50ml distilled water, then add 0.6ml hydrochloric acid, 0.5g copper chloride and 1g sodium dodecylbenzene sulfonate in sequence, and stir well . Heat the prepared etching solution on the heating furnace until the etching solution boils, and then clamp the processed sample with tweezers so that the polished surface is facing down, and hang it in the etching solution in the beaker. After 15 seconds of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com