Method for preparing high-thermal-conductivity coating for aluminum-based copper-clad plate

An aluminum-based copper-clad laminate with high thermal conductivity technology, applied in the field of copper-clad laminates, can solve the problems of reduced withstand voltage, easy cracking, high brittleness, etc., to increase cladding, improve electrical insulation performance and withstand voltage performance, The effect of reducing microbubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] The method for preparing a high thermal conductivity adhesive film for an aluminum-based copper-clad laminate provided in this embodiment includes the following steps:

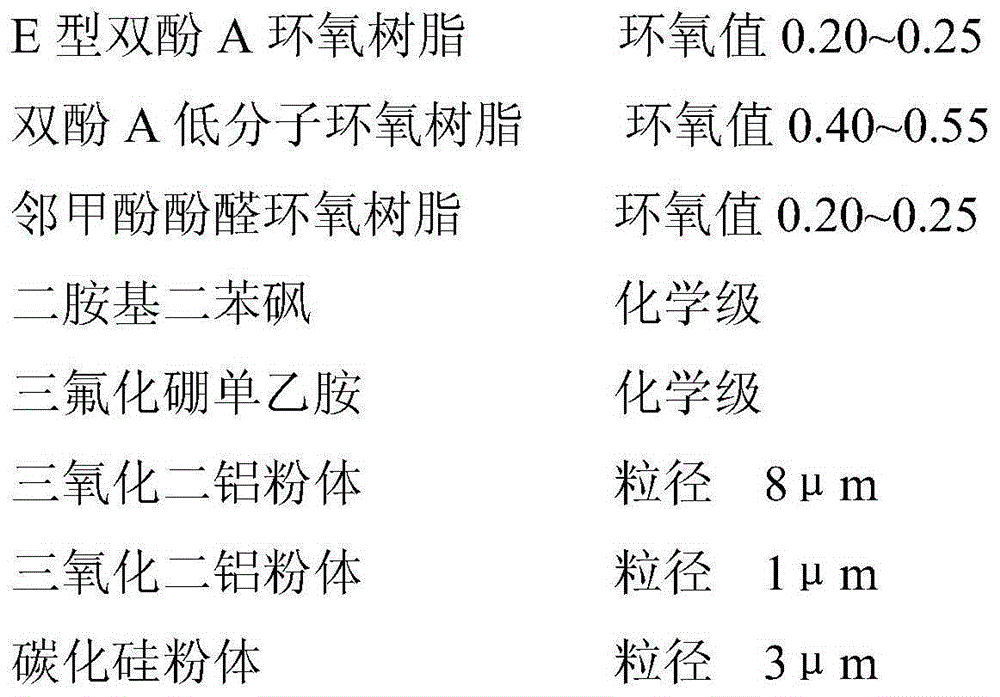

[0028] (1) Provide raw materials for the following components:

[0029] material name

Mass (grams)

mass ratio

E type bisphenol A epoxy resin

60

11.25%

30

5.62%

Bisphenol A Low Molecular Epoxy Resin

10

1.88%

Diaminodiphenylsulfone

25

4.69%

boron trifluoride monoethylamine

0.5

0.09%

silicone rubber

8

1.50%

50

9.38%

25

4.69%

50

9.38%

20

3.75%

10

1.88%

50

9.38%

90

16.87%

100

18.75%

...

example 2

[0044] The method for preparing a high thermal conductivity adhesive film for an aluminum-based copper-clad laminate provided in this embodiment includes the following steps:

[0045] (1) Provide raw materials for the following components:

[0046] material name

Mass (grams)

mass ratio

E type bisphenol A epoxy resin

85

16.14

10

1.90

Bisphenol A Low Molecular Epoxy Resin

5

0.95

Diaminodiphenylsulfone

15

2.85

boron trifluoride monoethylamine

0.6

0.11

silicone rubber

3

0.57

50

9.49

25

4.75

50

9.49

20

3.80

10

1.90

Aluminum oxide powder (1μm)

60

11.39

70

13.29

Aluminum oxide powder (8μm)

120

22.79

3

0.57

...

example 3

[0061] The method for preparing a high thermal conductivity adhesive film for an aluminum-based copper-clad laminate provided in this embodiment includes the following steps:

[0062] (1) Provide raw materials for the following components:

[0063] material name

Mass (grams)

mass ratio

E type bisphenol A epoxy resin

70

12.94%

O-Cresol Novolak Epoxy Resin

25

4.62%

Bisphenol A Low Molecular Epoxy Resin

5

0.92%

Diaminodiphenylsulfone

20

3.70%

boron trifluoride monoethylamine

0.8

0.15%

silicone rubber

10

1.85%

50

9.25%

25

4.62%

50

9.25%

20

3.70%

10

1.85%

Aluminum oxide powder (1μm)

60

11.09%

90

16.64%

Aluminum oxide powder (8μm)

100

18.49%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com