Method for producing NFC (nano-fibrillated cellulose)

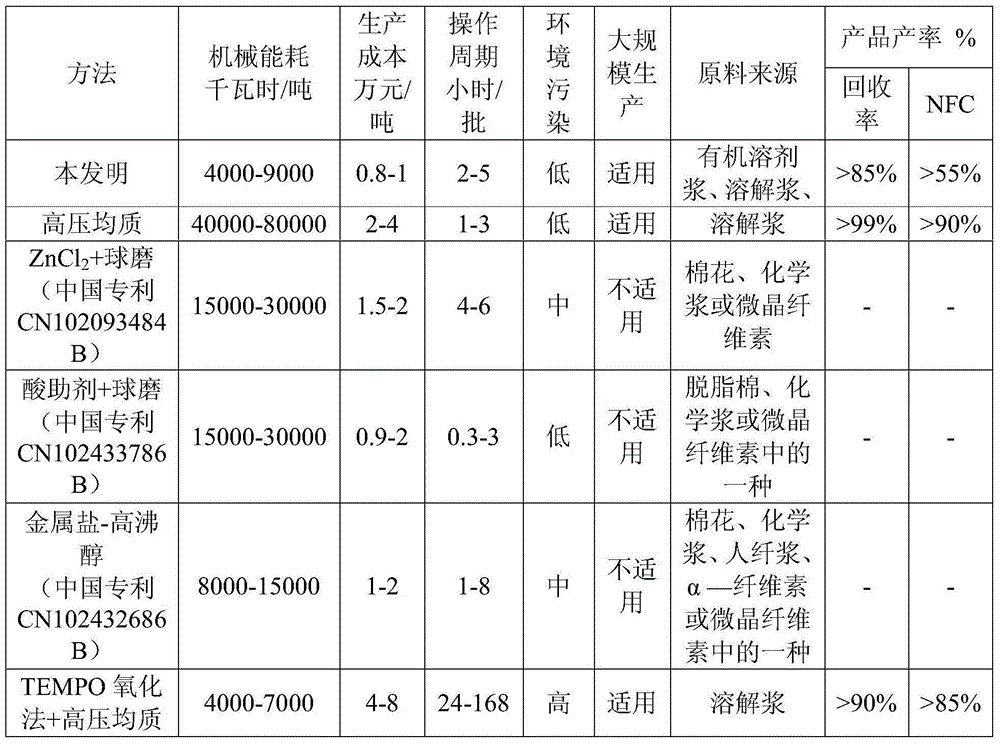

A technology of cellulose and cellulase, applied in the fields of green chemistry and biomass energy and materials, can solve the problems of large consumption of TEMPO reagents, environmental pollution, high cost, etc., and achieve the effect of saving mechanical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing cellulose nanofilament, the specific steps are as follows:

[0034] (1) 200 grams of poplar dissolving pulp boards were pre-soaked with 5 times the weight of distilled water for 60 minutes at room temperature (25° C.), and fully disintegrated. Adjust the slurry concentration to 15% (w / w) and use a medium-concentration hydraulic disc refiner for pretreatment. The pulp freeness was reduced to 130.

[0035] (2) Use NaAC-HAC buffer (pH=5.0) with a concentration of 0.1M to adjust the slurry concentration to 5% (w / w). The amount of cellulase added is 2.0×10 4 FPU / kg dry pulp. The raw materials and the reaction solution were thoroughly mixed, and kept at 50° C. for 30 minutes.

[0036] (3) Acidic oxidation solution is prepared by mixing 70% (w / w) hydrogen peroxide solution and 72% (w / w) sulfuric acid solution at 15°C, the molar ratio is 1:1.9, and the reaction time is 50 minutes. The stabilizer MgSO was added dropwise to the reaction solution 4 The...

Embodiment 2

[0040] A method for producing cellulose nanofilament, the specific steps are as follows:

[0041] (1) 300 grams of spruce organic solvent pulp, with a freeness of 100 after disc refining.

[0042] (2) The use concentration is 0.2MK 2 HPO 4 -KH 2 PO 4 Buffer (pH=7.0) was used to adjust the slurry concentration to 10% (w / w). The amount of xylanase added was 4.0×10 5 IU / kg dry pulp. The raw materials and the reaction solution were thoroughly mixed, and kept at 70° C. for 60 minutes.

[0043] (3) Alkaline oxidation solution is prepared by mixing 50% (w / w) hydrogen peroxide solution and 98% (w / w) sulfuric acid solution at 15°C, the molar ratio is 1:1.6, and the reaction time is 60 minutes. 1M K was added dropwise to the reaction solution 2 CO 3 The solution, the dropwise amount is alkaline reagent: sulfuric acid molar ratio is 1:1.5. Then add SDS at a final concentration of 0.1M as a diffusing agent. The yield of potassium persulfate was 50% of theory.

[0044] (3) The ...

Embodiment 3

[0047] (1) 300 grams of moso bamboo chemical pulp, with a freeness of 150 after refining with a disc refiner.

[0048] (2) Use K with a concentration of 0.2M 2 HPO 4 -KH 2 PO 4 Buffer (pH=7.0) was used to adjust the slurry concentration to 10% (w / w). The amount of mannanase added was 3.5×10 5 IU / kg dry pulp. The raw materials and the reaction solution were thoroughly mixed, and kept at 60° C. for 90 minutes.

[0049] (3) Alkaline oxidation solution is prepared by mixing 50% (w / w) hydrogen peroxide solution and 98% (w / w) sulfuric acid solution at 15°C, the molar ratio is 1:1.6, and the reaction time is 60 minutes. 1M K was added dropwise to the reaction solution 2 CO 3 The solution, the dropwise amount is alkaline reagent: sulfuric acid molar ratio is 1:1.5. The yield of potassium persulfate was 50% of theory.

[0050] (4) The pulp suspension pretreated by cellulase is filtered and washed twice with water, and the pulp concentration is adjusted to 8% (w / w). Potassium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com