Production method for tetraphenyl porphin

A technology of tetraphenylporphine and its production method, which is applied in organic chemistry and other fields, and can solve problems such as yield reduction, loss of pyrrole and aromatic aldehyde, and no countermeasures mentioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

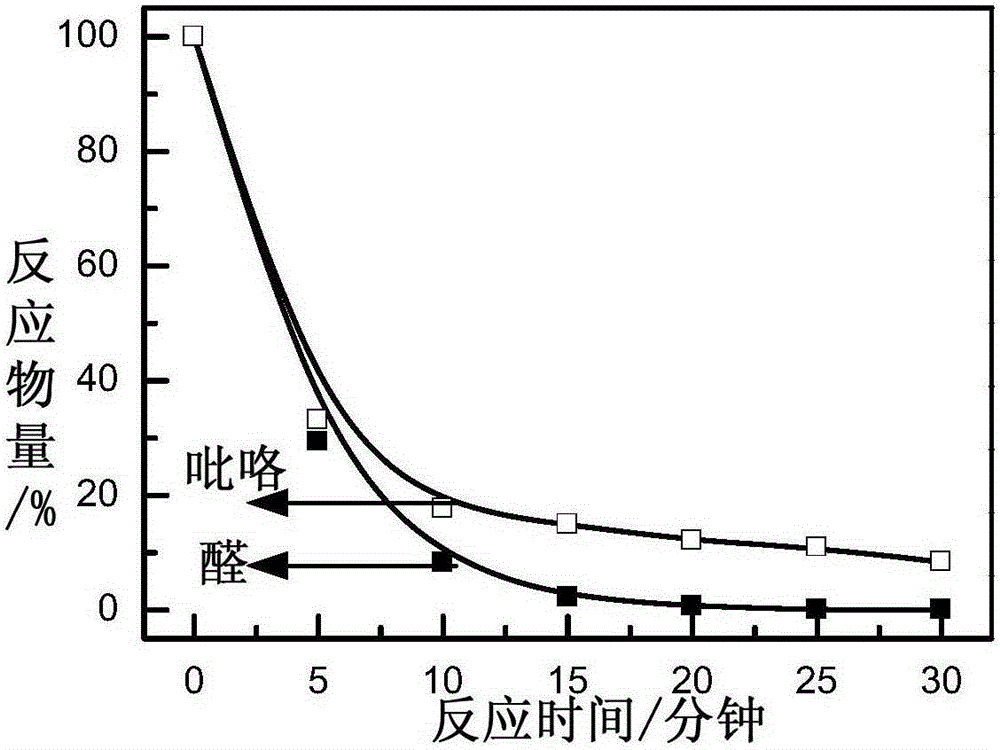

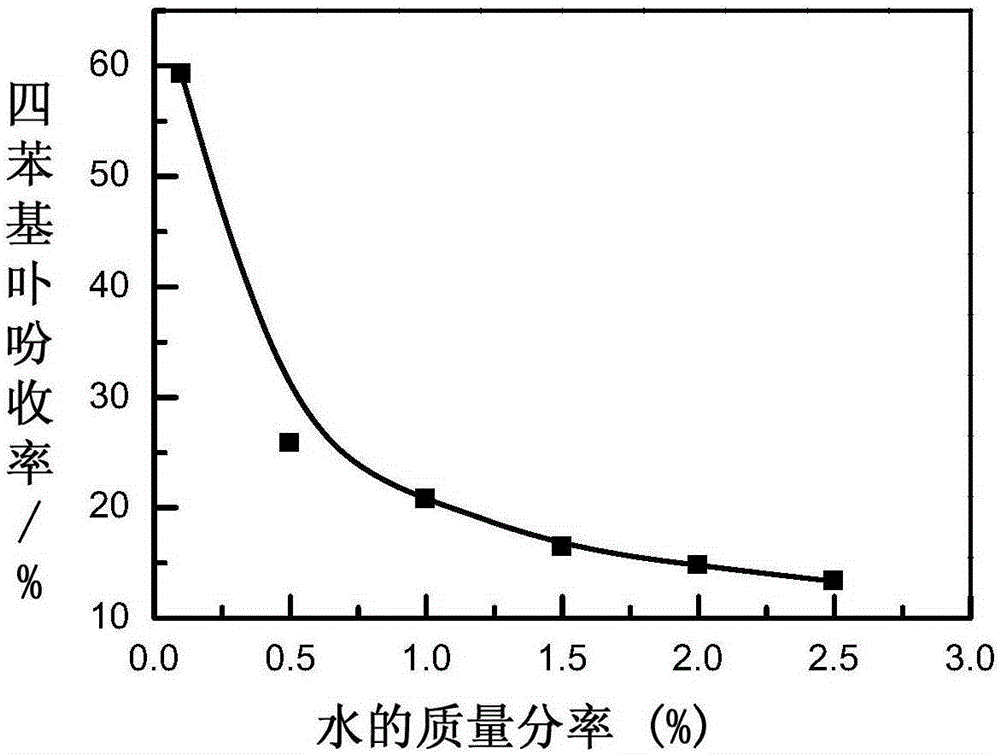

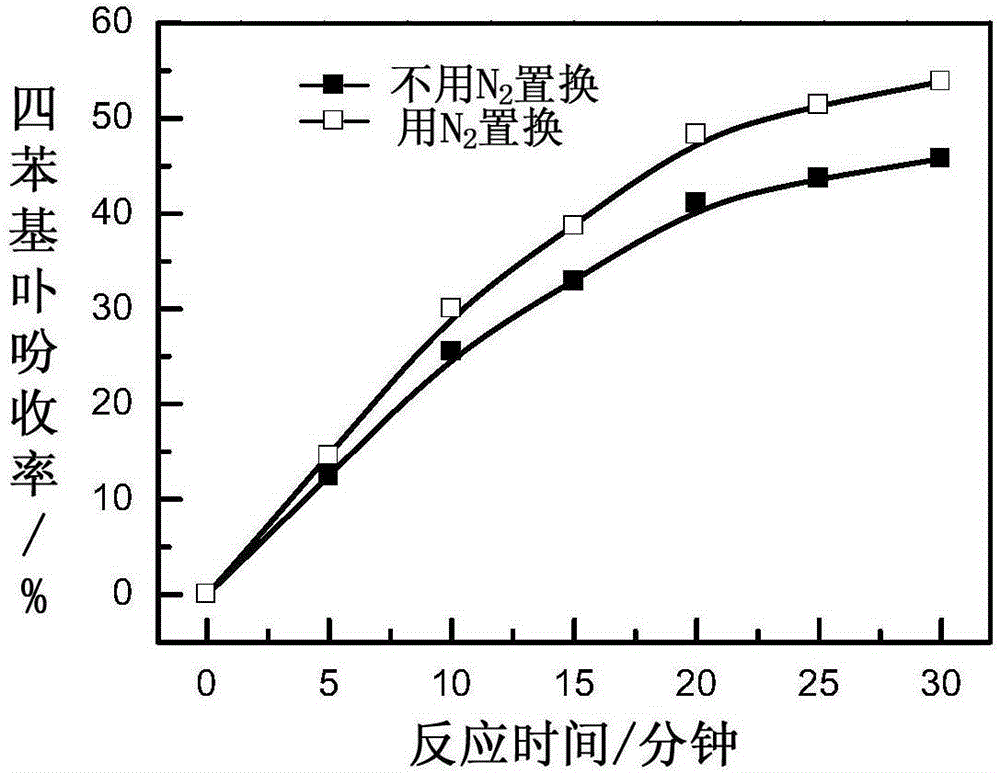

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) 560mol pyrrole and 560mol benzaldehyde are made into mixed solution, for subsequent use;

[0061] (2) In the 2000L titanium material high-pressure polymerization reactor 1 with mechanical stirring and electric heating jacket, top belt distillation device, add the solvent E that is made up of the cyclohexane of 840L propionic acid and 560L, and from the polymerization reactor 1 Bottom drum into N 2 The oxygen concentration in the gas phase at the outlet of the condenser on the top of the reactor is lower than 1%, and then the electric heating jacket switch of the polymerization reactor 1 is started, the liquid in the polymerization reactor 1 is heated to reflux, and the pressure of the polymerization reactor 1 is maintained at 5.0 atm. At the same time, the mixed solution prepared in step (1) is added dropwise from the top of the polymerization reactor 1, and the molar concentration of pyrrole in the reaction solution is always maintained to be lower than 0.1mol / L du...

Embodiment 2

[0064] Technical process is identical with embodiment 1, difference is:

[0065] (1) add 140mol pyrrole and 280mol p-chlorobenzaldehyde;

[0066] (2) Solvent E is a mixture of 980L propionic acid and 420L toluene;

[0067] (3) The reaction time in the polymerization reactor was 9 minutes, the pressure was controlled at 3 atm, and the temperature was 152.4 ° C when the reaction ended, and the water concentration in the polymerization reactor was controlled to be lower than 0.08% all the time;

[0068] (4) The gas that feeds in the oxidation reactor is pure oxygen, and the reaction time is 18 minutes;

[0069] (5) The crude TPP filter cake is 15.2kg;

[0070] According to this method, the finally obtained solid was vacuum-dried at 80° C. to obtain 12.8 kg of the product TPP, and the amount of pyrrole remaining in the polymerization reaction system was 8.8 mol. The synthesis yield of the product TPP based on the reactant pyrrole is 51.8%, and the purity is 99.5%.

Embodiment 3

[0072] Technical process is identical with embodiment 1, difference is:

[0073] (1) add 840mol pyrrole and 840mol m-chlorobenzaldehyde;

[0074] (2) Solvent E is a mixture of 1120L propionic acid and 280L benzene, the pressure is controlled at 2.8atm, the temperature is 148.8°C at the end of the reaction, and the water concentration in the polymerization reactor is controlled to be lower than 0.04% all the time;

[0075] (3) the reaction time in the polymerization reactor is 12 minutes;

[0076] (4) The gas that feeds in the oxidation reactor is air, and the reaction time is 12 minutes;

[0077] (5) The crude TPP filter cake is 98.7kg;

[0078] According to this method, the finally obtained solid was vacuum-dried at 80° C. to obtain 82.8 kg of product TPP, and the amount of pyrrole remaining in the polymerization reaction system was 48.8 mol. The synthesis yield of the product TPP based on the reactant pyrrole is 55.6%, and the purity is 99.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com