Preparation method for 2-aryl-2-glycollic acid esters

A technology of glycolic acid ester and aryl group, which is applied in the field of medicine, can solve the problems of unsuitability for industrial production, difficulty in purification, and many by-products, and achieve the effects of mild conditions, reduced side reactions, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

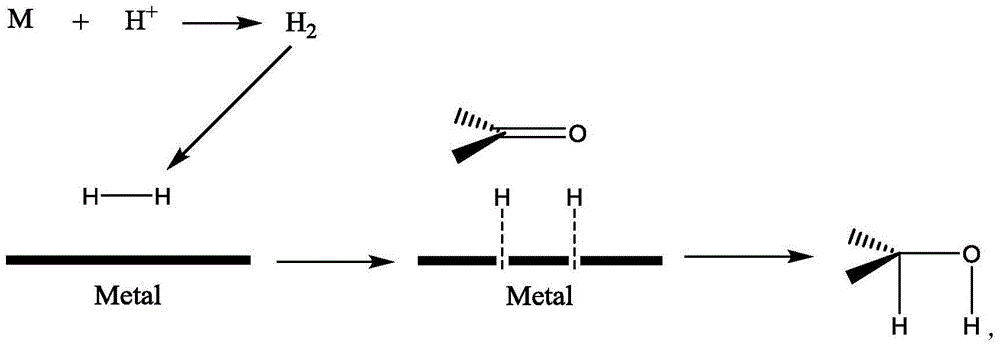

Method used

Image

Examples

Embodiment 1

[0029] Preparation of ethyl 2-(2-fluoro-3-methoxyphenyl)-2-hydroxyacetate

[0030] Ethyl 2-(2-fluoro-3-methoxyphenyl)-2-oxoacetate (69.95g, 0.31mol) was dissolved in 600mL of absolute ethanol, cooled to 0-5°C with ice-water, added Zinc powder (80.6g, 1.24mol) and glacial acetic acid (142mL, 2.25mol) were stirred at 25°C for 4 hours. Use saturated sodium carbonate solution to adjust the pH to 9 (solid sodium carbonate can be added appropriately), filter with suction, wash the filter cake with absolute ethanol, concentrate to remove ethanol, extract the filtrate with ethyl acetate (250mL×3), and use anhydrous Dried over magnesium sulfate and concentrated to dryness yielded 68.81 g of product. Product purity 95.26%, yield: 97.52%; Product characterization: MS (m / z): 229.1 [MH + ]; 1 HNMR (DMSO-d 6 )δ:1.12(t,3H),3.83(s,3H),4.07(q,2H),5.31(d,1H),6.17(d,1H),6.96-7.01(m,1H),7.10-7.13 (m,2H).

Embodiment 2

[0032] Preparation of 2-(2-fluoro-3-methoxyphenyl)-2-hydroxyacetic acid methyl ester

[0033] Methyl 2-(2-fluoro-3-methoxyphenyl)-2-oxoacetate (2.12g, 0.01mol) was dissolved in 30mL of absolute ethanol, cooled to 0-5°C with ice-water, added Zinc powder (1.95 g, 0.03 mol) and acetic acid (2.3 mL, 0.04 mol) were stirred at 25°C for 4 hours. Use saturated sodium carbonate solution to adjust the pH to 9 (solid sodium carbonate can be added appropriately), filter with suction, wash the filter cake with absolute ethanol, concentrate to remove ethanol, extract the filtrate with ethyl acetate (20mL×3), and use anhydrous Dried over magnesium sulfate and concentrated to dryness yielded 2.08 g of product. Product purity 93.63%, yield: 97.19%; Product characterization: MS (m / z): 215.2 [MH + ]; 1 HNMR (DMSO-d 6 )δ: 3.53 (s, 3H), 3.84 (s, 3H), 5.30 (d, 1H), 6.18 (d, 1H), 6.95-7.00 (m, 1H), 7.11-7.13 (m, 2H).

Embodiment 3

[0035] Preparation of Propyl 2-(2-fluoro-3-methoxyphenyl)-2-hydroxyacetate

[0036] Propyl 2-(2-fluoro-3-methoxyphenyl)-2-oxoacetate (2.40g, 0.01mol) was dissolved in 30mL methanol, cooled to 0-5°C with ice-water, and iron powder was added (1.68g, 0.03mol) and glacial acetic acid (2.3mL, 0.04mol), stirred at 25°C for 12 hours. Use saturated sodium carbonate solution to adjust the pH to 9 (solid sodium carbonate can be added appropriately), filter with Celite salt, wash the filter cake with methanol, concentrate the methanol, and extract the filtrate with ethyl acetate (20mL×3), and use the organic phase with Dry over magnesium sulfate and concentrate to dryness to obtain 2.32 g of product. Product purity 93.03%, yield: 95.87%; Product characterization: MS (m / z): 243.2 [MH + ].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com