Preparation method of sheet-shaped C/C-MoSi2 composite

A composite material and sheet-like technology, which is applied in the field of preparation of sheet-like C/C-MoSi2 composite materials, can solve the problems of decreased strength of fiber reinforcements, low mechanical properties of composite materials, low stability of composite materials, etc. junction strength, improved interfacial bonding, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

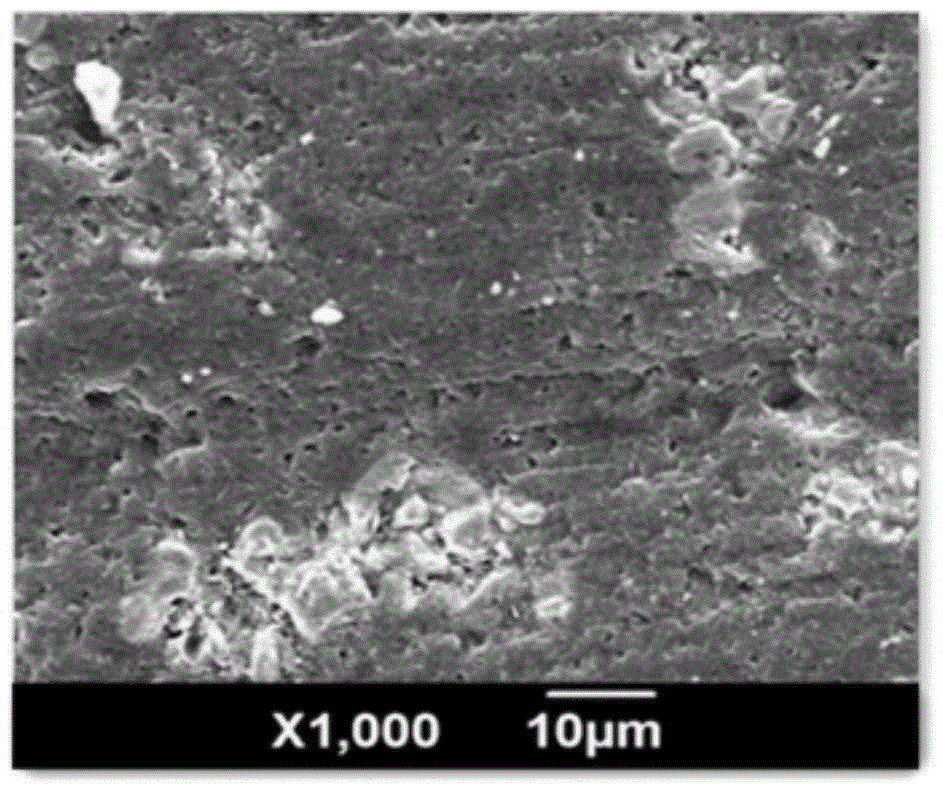

Image

Examples

Embodiment 1

[0032] 1) Select commercially available molybdenum disilicide powder (after dry ball milling for 24 hours, the average particle size is controlled at 1-3 μm), isopropanol (purity ≥ 99.8%), glucose (purity ≥ 99%) as raw materials;

[0033] 2) First, take an appropriate amount of molybdenum disilicide powder 6g and disperse it in 150mL of isopropanol to prepare a mixture with a concentration of 40g / L. The mixture is ultrasonically oscillated (ultrasonic power is 800W) for 50min, and then placed on a magnetic stirrer and stirred for 2h , to get a suspension;

[0034] 3) Set the density to 0.2g / cm 3 The carbon fiber three-dimensional fabric (manufacturer: Jiangsu Tianniao High-tech Co., Ltd.) is cut into discs with a diameter of 3 cm and a thickness of 0.5 cm;

[0035] 4) Place the disc in 0.5mol / L glucose solution for 180°C homogeneous hydrothermal treatment for 6 hours, deposit a carbon layer on the carbon fiber to protect the fiber, and increase the density to obtain a C / C sam...

Embodiment 2

[0042] 2) First, take an appropriate amount of molybdenum disilicide powder 5.25g and disperse it in 150mL of isopropanol to prepare a mixture with a concentration of 35g / L. The mixture is ultrasonically oscillated (ultrasonic power is 800W) for 30min, and then placed on a magnetic stirrer for stirring 2h, the suspension was obtained;

[0043] 3) Set the density to 0.3g / cm 3 The carbon fiber three-dimensional fabric (manufacturer: Jiangsu Tianniao High-tech Co., Ltd.) is cut into discs with a diameter of 4cm and a thickness of 1cm;

[0044] 4) Place the wafer in 0.75mol / L glucose solution for 200°C homogeneous hydrothermal treatment for 6 hours, deposit a carbon layer on the carbon fiber to protect the fiber and increase the density to obtain a C / C sample;

[0045] 5) Place the C / C sample prepared in step 4) flat in the glass sand core suction filter device, then pour the suspension into a vacuum filter flat-bottomed funnel, and perform suction filtration. The vacuum pump pum...

Embodiment 3

[0050] 1) Select commercially available molybdenum disilicide powder (after dry ball milling for 24 hours, the average particle size is controlled at 1-3 μm), isopropanol (purity ≥ 99.8%), glucose (purity ≥ 99%) as raw materials;

[0051] 2) First, take an appropriate amount of molybdenum disilicide powder 6.75g and disperse it in 150mL of isopropanol, and prepare a mixture with a concentration of 45g / L. The suspension is ultrasonically oscillated (ultrasonic power is 800W) for 50min, and then placed on a magnetic stirrer Stir for 2h to obtain a suspension;

[0052] 3) Set the density to 0.4g / cm 3 The carbon fiber three-dimensional fabric is cut into discs with a diameter of 3cm and a thickness of 2cm;

[0053] 4) Place the disc in 0.5mol / L glucose solution for 190°C homogeneous hydrothermal treatment for 8 hours, deposit a carbon layer on the carbon fiber to protect the fiber, and increase the density to a certain extent to obtain a C / C sample;

[0054] 5) Place the C / C sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com