Glue squeezing device for producing three-dimensional fiber reinforced composite materials

A fiber-reinforced and composite material technology, which is applied in the field of extruding devices for preparing composite materials, can solve problems such as poor consistency of glue content, difficulty in control, and increased production costs, so as to improve extrusion efficiency, reduce production costs, and eliminate glue. The effect of fluid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

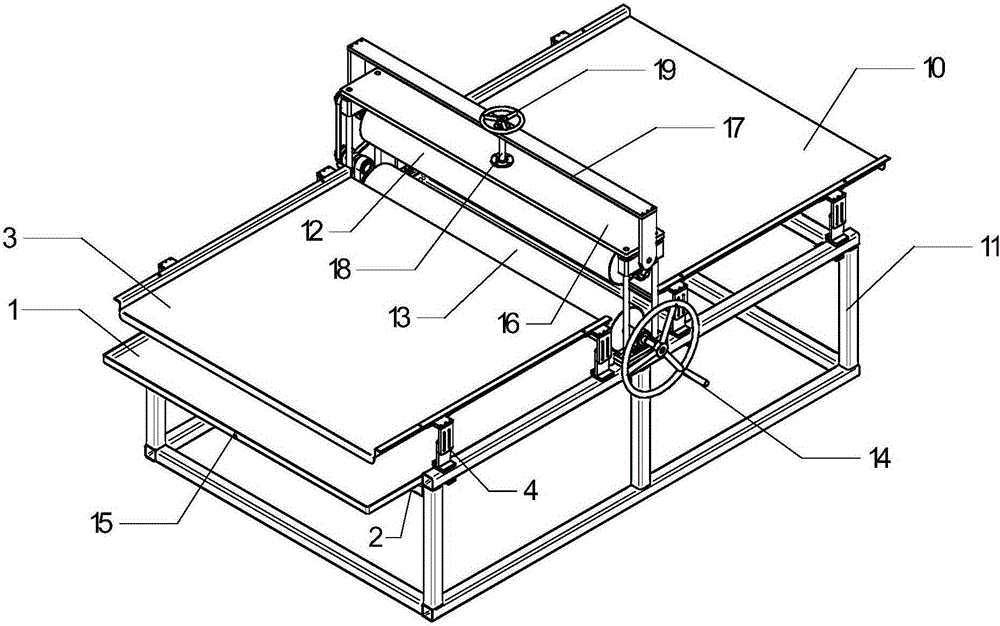

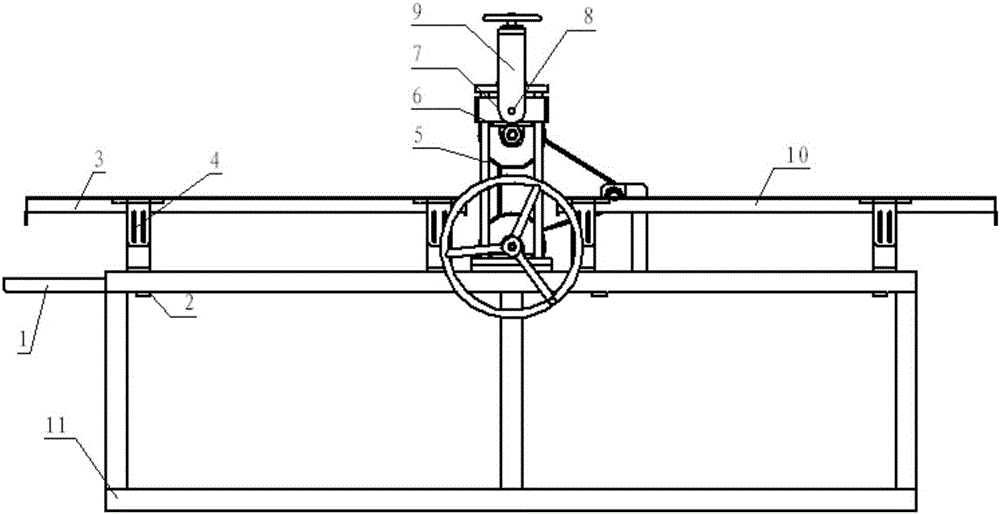

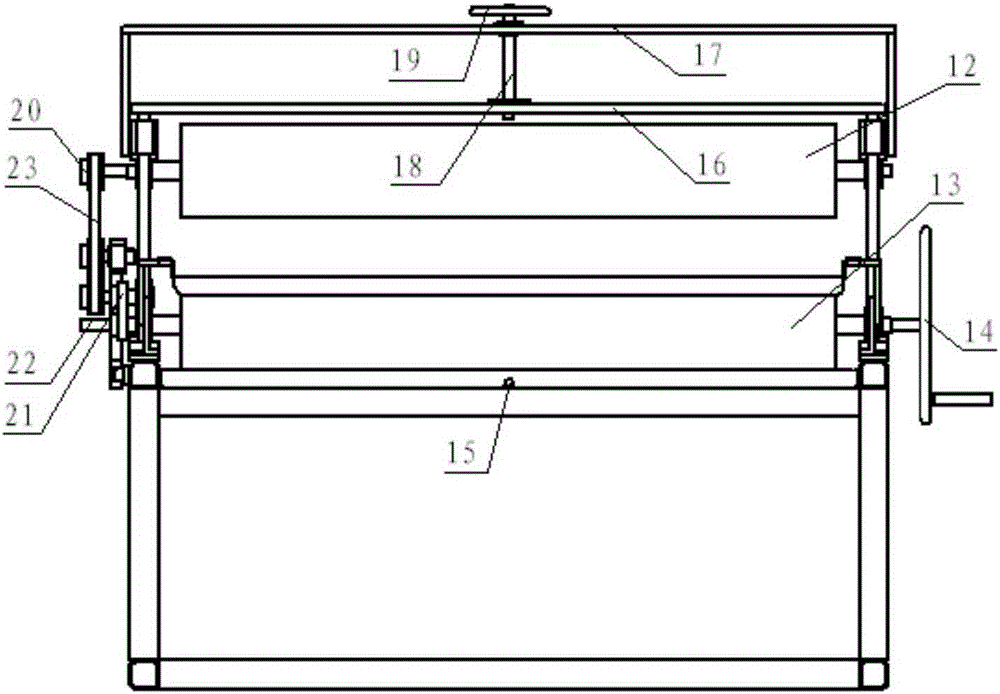

[0027] A squeezing device for preparing three-dimensional fiber-reinforced composite materials, comprising: flow glue plate 1, flow glue plate seat 2, feeding pallet 3, adjustable pallet bracket 4, support shaft 5, bearing base 6, upper roller slide Block 7, slider connecting shaft 8, slider connecting plate 9, receiving pallet 10, bracket 11, upper roller 12, lower roller 13, manual handwheel 14, glue hole 15, top plate 16, moving plate 17, screw rod 18. Pitch adjusting hand wheel. 19. Synchronous transmission mechanism.

[0028] Such as figure 1 , figure 2 As shown, the bracket 11 is a frame structure; both ends of the moving plate 17 are screwed to the slider connecting plate 9, and the slider connecting plate 9 is connected to the upper roller slider 7 through the slider connecting shaft 8. This hinge connection method can reduce the The requirements of the machining accuracy and assembly accuracy of the parts improve the operability of the equipment; both ends of the top pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com