Catalytic cracking catalyst and preparation method and application thereof

A catalytic cracking and catalyst technology, used in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problem of high coke selectivity, achieve high liquefied gas yield, low coke selectivity, and increase catalytic cracking catalysts. The effect of pore content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

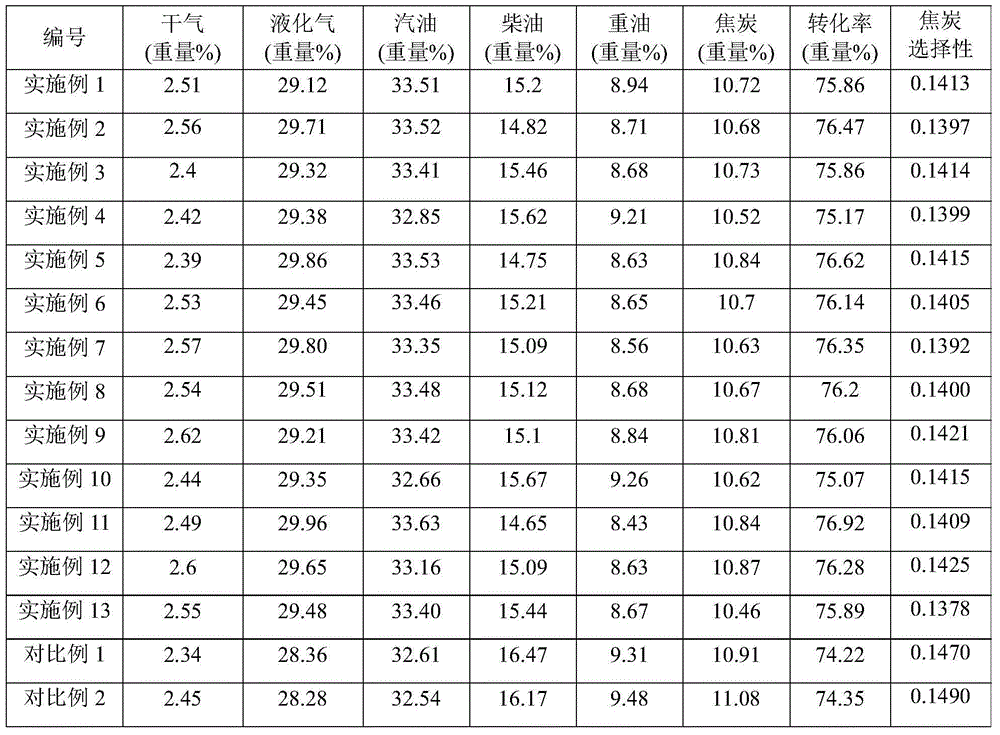

Examples

preparation example Construction

[0023] In the preparation process of the above-mentioned modified aluminum sol, water can be introduced into the reactor through a soluble silicon-containing compound solution, through a chloride solution, through a soluble phosphorus-containing compound solution, by adding water such as deionized water, or through a combination of the above methods Water is introduced into the reactor, preferably, the weight ratio of the water introduced into the reactor before adding the chloride to the soluble silicon-containing compound (calculated as Si) introduced into the reactor before adding the chloride is 100:0.1-10 , such as 100:1-10 or 100:0.1-5 or 100:0.15-1.4 or 100:0.2-1.3:1.

[0024] The content of silicon (calculated as silicon element) in the modified aluminum sol obtained in the present invention is 0.1-1 wt%, preferably 0.2-0.9 wt%, for example 0.3-0.85 wt%.

[0025] In the preparation process of the above-mentioned modified aluminum sol, the amount of metal aluminum added...

preparation example

[0068] In the following preparation examples, comparative preparation examples, examples and comparative examples:

[0069]The purity of aluminum chips used is 99.2% by weight, and the purity of aluminum particles is 98.8% by weight; the 1:1 chemically pure hydrochloric acid used is a mixture of 1 volume concentration of 36% by weight chemically pure hydrochloric acid and 1 volume water; the 1:1 chemically pure phosphoric acid used It is a mixture of 1 volume of chemically pure phosphoric acid with a concentration of 85% by weight and 1 volume of water; the rare earth chloride is purchased from Baotou Steel Rare Earth High Technology Co., Ltd., and the rare earth elements are La and Ce.

[0070] The specific surface area, pore volume and average pore diameter were all measured by the low-temperature nitrogen adsorption-desorption method, and the instrument used was the physical and chemical adsorption instrument ASAP2400 of Micromeritics Company in the United States; 2 O, Al ...

preparation example 1

[0075] This preparation example is used to illustrate the preparation method of the silicon-modified aluminum sol provided by the present invention.

[0076] 286 grams of aluminum chips (calculated as Al), 1481 grams of deionized water and 119 grams of water glass aqueous solution (containing 9.33% by weight of Si element and 4.63% by weight of Na element) were added into the three-necked flask and heated to 60°C. Slowly add 921 ml of 1:1 chemically pure hydrochloric acid into the three-necked flask to make it react with aluminum chips. The addition time of hydrochloric acid is 3 hours; The product was cooled to 60-70°C and filtered to obtain modified aluminum sol SA-1. The residual aluminum chips from the reaction were weighed to be 36 grams, that is, the aluminum excess was 14.8% by weight. After analyzing the modified aluminum sol SA-1, the results are as follows: Al content is 9.0% by weight, Cl content is 6.7% by weight, Si content is 0.41% by weight, Al / Cl (weight ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com