Composite semifinished products and mouldings produced therefrom and directly produced mouldings based on hydroxy-functionalized (meth)acrylates and uretdiones which are crosslinked by means of radiation to give thermosets

A technology of acrylate and molded products, which is applied in the field of preparing storage-stable polyurethane prepregs to achieve good mechanical properties, high flexibility, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

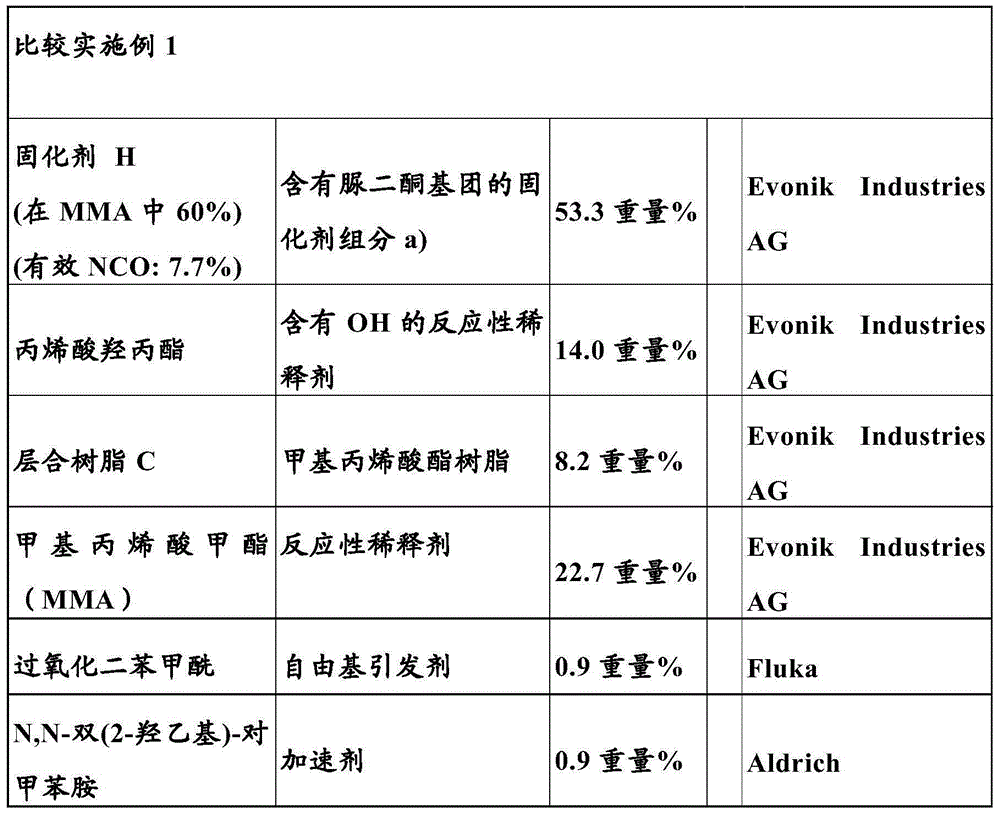

Examples

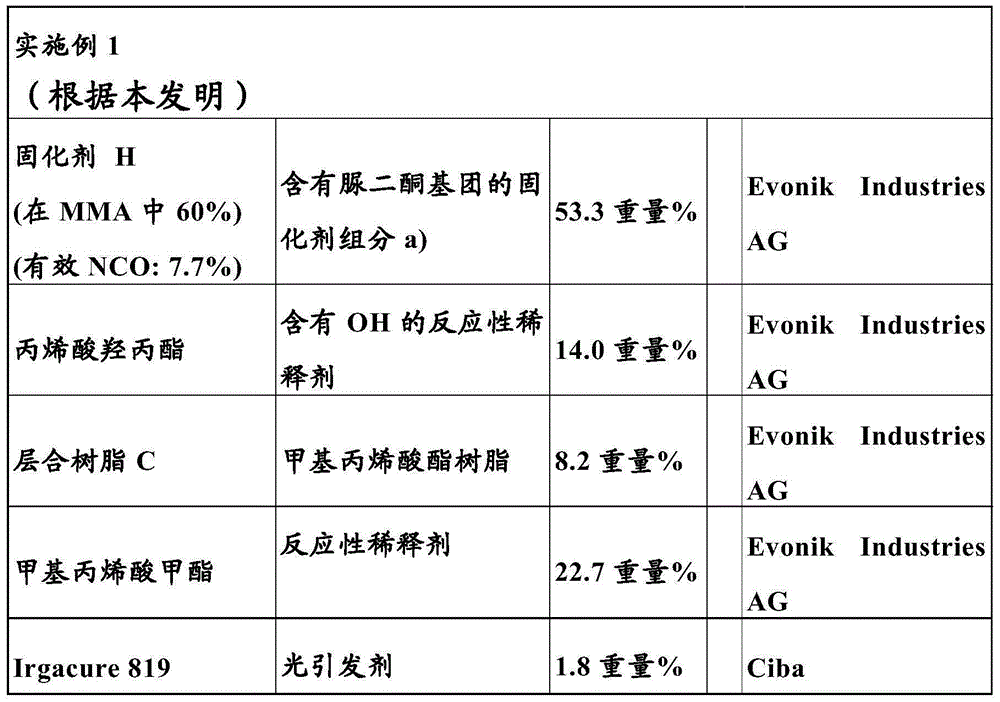

Embodiment 1

[0110] The prepreg of Example 1 exhibited a weight loss of about 34% based on the substrate after drying.

[0111] The impregnated glass fiber mat was pressed at 180° C. and 50 bar for 1 hour (Polystat 200T from the company Schwabenthan) and was completely crosslinked there. The hard, rigid, chemical resistant and impact resistant composite component (sheet material) has a Tg of 119°C.

[0112]

[0113] The starting materials in this table were mixed intimately in a pre-mixer and then dissolved. The mixture can be stored for about 1 to 2 years without gelling, under conditions where light is excluded.

[0114] To prepare the prepreg, the glass fiber woven is impregnated with a solution of the matrix material. Then use UVLED lamps below (Heraeus Water-cooled heat sink, wavelength: 395±5nm, power density: 8W / cm at 5mm operating distance 2 ;Launch window: 251×35mm 2 ) was dried at 1.5 m / min. The fiber mass content determined in Example 1 was 54%. The prepreg of Example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com