Aluminium-plastic composite tube for cable and preparation method thereof

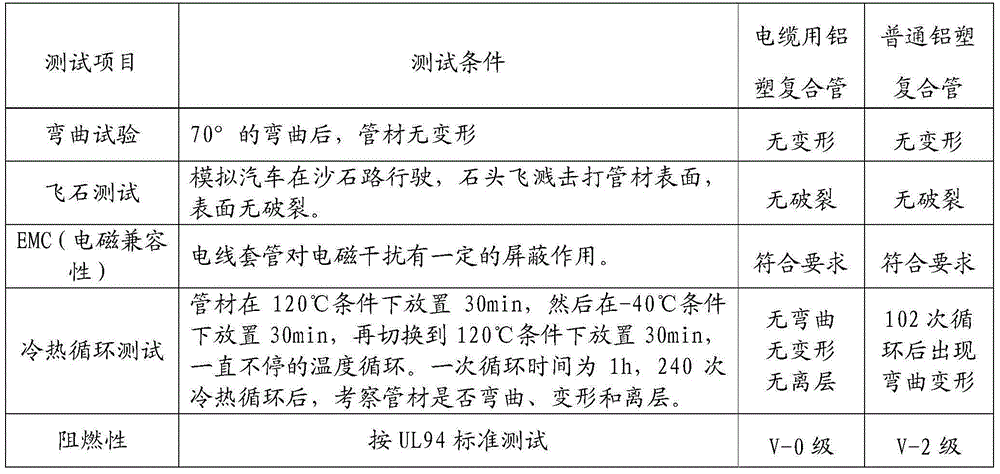

A technology of aluminum-plastic composite pipe and cable, which is applied in applications, electrical components, household appliances, etc., can solve the problems of insufficient rigidity, easy-leaf layer falling off, low hardness and tensile strength, etc., and achieve good corrosion resistance and Anti-rust performance, long service life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing an aluminum-plastic composite pipe for cables, the outer diameter of the aluminum-plastic composite pipe 100 is 20mm, the inner diameter is 17mm, the first plastic layer 10 and the second plastic layer 70 are orange, and it includes the following steps (the following parts Numbers are parts by weight):

[0053] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, 15 parts of flame-retardant masterbatch, 5 parts of weather-resistant masterbatch and 3 parts of color masterbatch, fully stir for 13 minutes with a high-speed mixer, and put it into the second plastic layer extrusion During discharge, the barrel temperature is 170°C;

[0054] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, 20 parts of flame-retardant masterbatch, and 3 parts of color masterbatch, fully stir with a high-speed mixer for 16 minutes, and then put it into the first plastic layer extruder. Cylinder temperature is 175°C;

[0...

Embodiment 2

[0061] A preparation of an aluminum-plastic composite pipe for cables, the outer diameter of the aluminum-plastic composite pipe is 25mm, the inner diameter is 21mm, the first plastic layer and the second plastic layer are orange, and it comprises the following steps (the following parts are all by weight share):

[0062] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, 15 parts of flame-retardant masterbatch, 5 parts of weather-resistant masterbatch and 3 parts of color masterbatch, stir fully with a high-speed mixer for 15 minutes, and put it into the second plastic layer In the extruder, the barrel temperature is 175°C;

[0063] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, and 20 parts of flame-retardant masterbatch, fully stir with a high-speed mixer for 17 minutes, and then put it into the first plastic layer extruder, and the barrel temperature is 170 ° C;

Embodiment 3

[0070] A preparation of an aluminum-plastic composite pipe for cables, the outer diameter of the aluminum-plastic composite pipe is 25mm, the inner diameter is 21mm, the first plastic layer and the second plastic layer are orange, and it comprises the following steps (the following parts are all by weight share):

[0071] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, 15 parts of flame-retardant masterbatch, 5 parts of weather-resistant masterbatch and 3 parts of color masterbatch, stir fully with a high-speed mixer for 10 minutes, and put it into the second plastic layer In the extruder, the barrel temperature is 150°C;

[0072] Mix 95 parts of low-density cross-linked polyethylene, 5 parts of catalyst, and 20 parts of flame-retardant masterbatch, fully stir with a high-speed mixer for 10 minutes, and then put it into the first plastic layer extruder, and the barrel temperature is 150 ° C;

[0073] Put the hot melt adhesive into the adhesive laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com