Preparation method for anti-dielectric substrate delamination of multi-layer fss radome

A radome and anti-dielectric technology, which is applied in the field of preparation of multi-layer FSS radome anti-dielectric substrate delamination, can solve the problems of mismatch between layers, poor exhaust, uneven thickness of dielectric layer, etc., and achieve operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

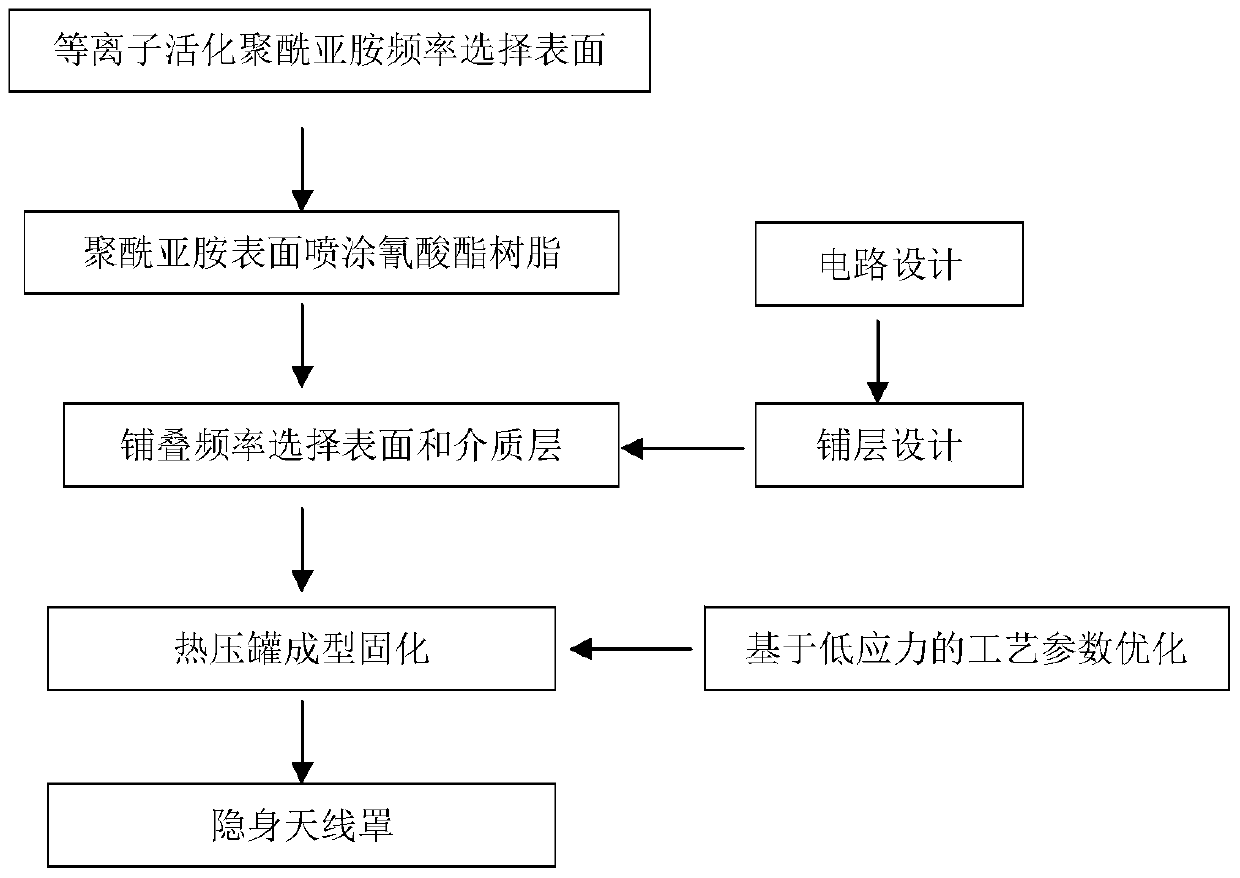

[0015] In the following, a radome using four layers of frequency selective surfaces will be selected as an example to further illustrate the present invention.

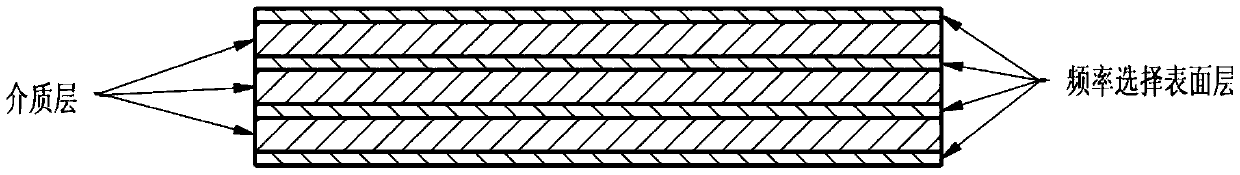

[0016] refer to figure 1 figure 2 . According to the present invention, the base material of the frequency selective surface of the multilayer frequency selective surface stealth radome is polyimide. The dielectric layer material of the multilayer frequency selective surface stealth radome is quartz fiber cloth reinforced cyanate resin composite material.

[0017] Before the radomes are laid, plasma activation is performed on the polyimide frequency selective surface and cyanate resin is sprayed for tackifying treatment; the gas for plasma activation treatment on the polyimide frequency selective surface is O2 , processing power 2.5Kw ~ 4Kw, processing time 30min ~ 50 min. After treatment, active groups appear on the frequency selective surface of polyimide, which increases the surface energy, improves the chemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com