Open-close type wire nose and connecting structure thereof

A connection structure, opening and closing technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of reducing work efficiency, increasing the workload of on-site staff, and the workload cannot be ignored, so as to avoid the difference in expansion coefficient of copper and aluminum , Overcome the effect of low hardness and low fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

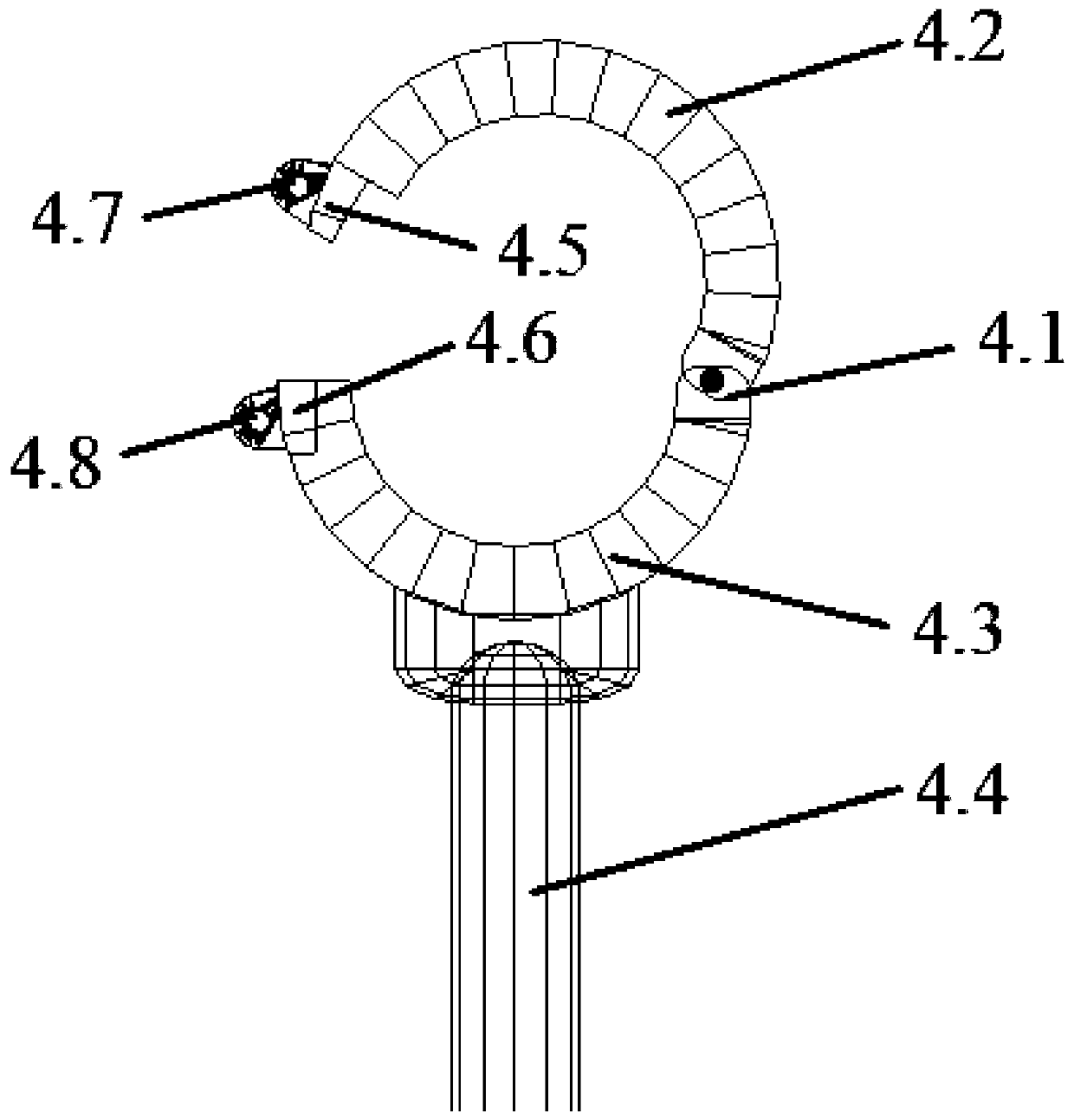

[0047] Such as figure 1 As shown, a split-type wire lug 4 includes a wire connecting pipe 4.4 and a ring, and the ring includes an upper ring 4.2, a lower ring 4.3 and a connecting part 4.1, wherein,

[0048] One end of the upper ring 4.2 is connected with one end of the connecting part 4.1;

[0049] The other end of the upper ring 4.2 is connected to the other end of the lower ring 4.3;

[0050] One end of the lower ring 4.3 is connected to the other end of the connecting part 4.1;

[0051] The lower ring 4.3 is connected with the wire connecting pipe 4.4.

[0052] In this embodiment, the ring has the function of opening and closing through the upper ring, the lower ring and the connecting parts, so that the ring can be taken off directly. Avoid needing to unscrew the nut all the way from the threaded rod to remove the lug.

[0053] In Embodiment 1, the following improvements can also be made: the connecting part 4.1 is a rotatable part, and the upper ring 4.2, the lower ...

Embodiment 2

[0067] Embodiment 2 is an extended example of Embodiment 1.

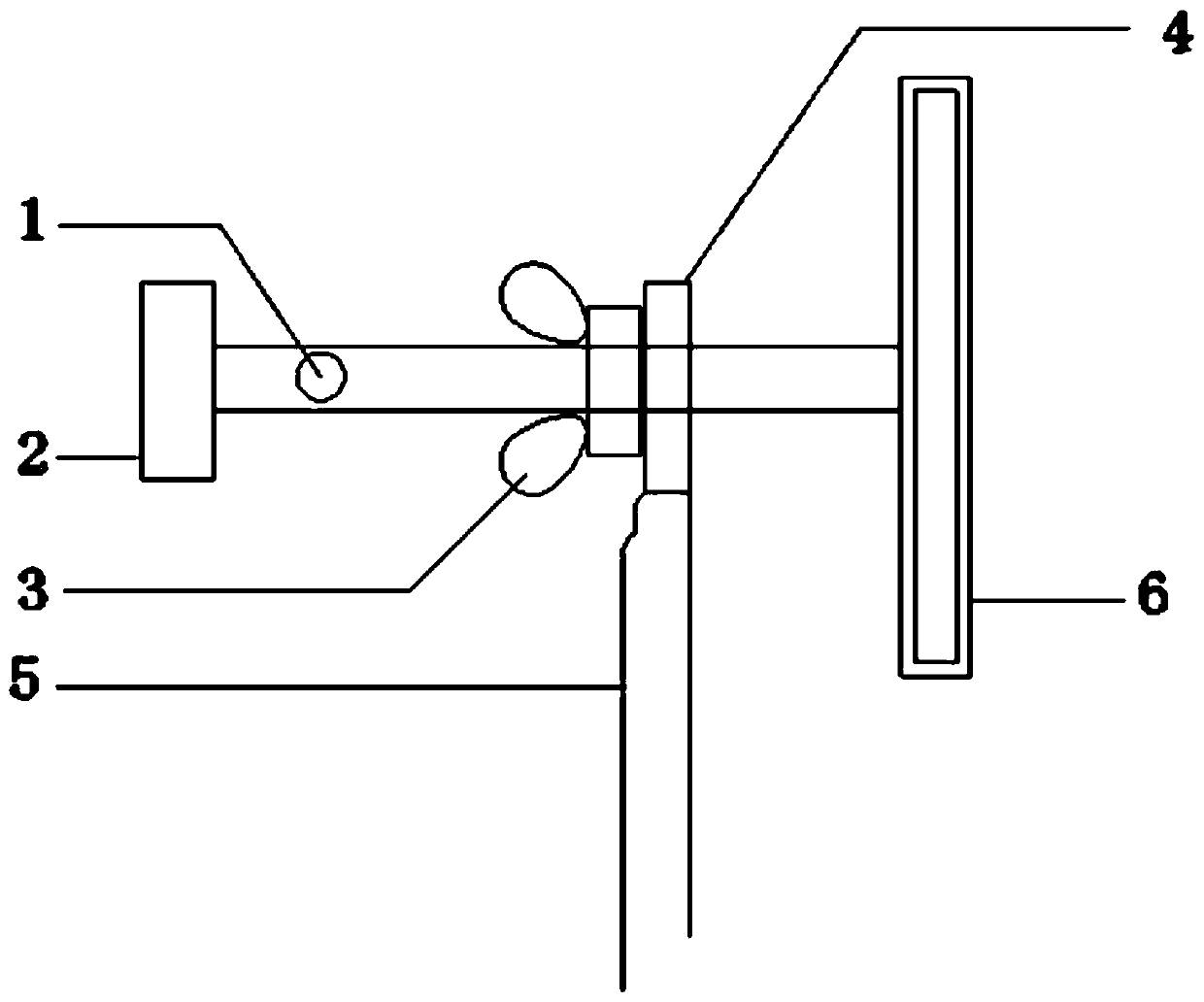

[0068] A connection structure, including the split-type wire lug 4 of Embodiment 1, and also includes bolts 2, nuts 3, grounding wires 5 and grounding rods 6, wherein,

[0069] The bolt 2 includes a head and a screw rod, the head is arranged on one end of the screw rod 2, and the head is fixedly connected with the screw rod 2;

[0070] The other end of the screw rod is meshed with the ground rod 6;

[0071] The nut 3 rotates and moves on the screw rod;

[0072] The wire connecting pipe 4.4 is connected with the ground wire 5;

[0073] The split-type wire lug 4 is located between the nut 3 and the grounding rod 6, and the nut 3 realizes a position-limiting function.

[0074] The course of work of embodiment 2:

[0075] Install the ground wire: turn the nut outward slightly, open the open-closed wire lug, insert it to the position to be connected, close the open-closed wire lug, and can choose to add a lock to loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com