A kind of preparation method of iron-based nanorod

A nanorod, iron-based technology, applied in the field of preparation of iron-based nanorods, can solve the problems of inability to carry out large-scale industrial production, unsuitable for industrial production, complex production process, etc., and achieves improved preparation efficiency and less environmental dependence. , the effect of short process cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

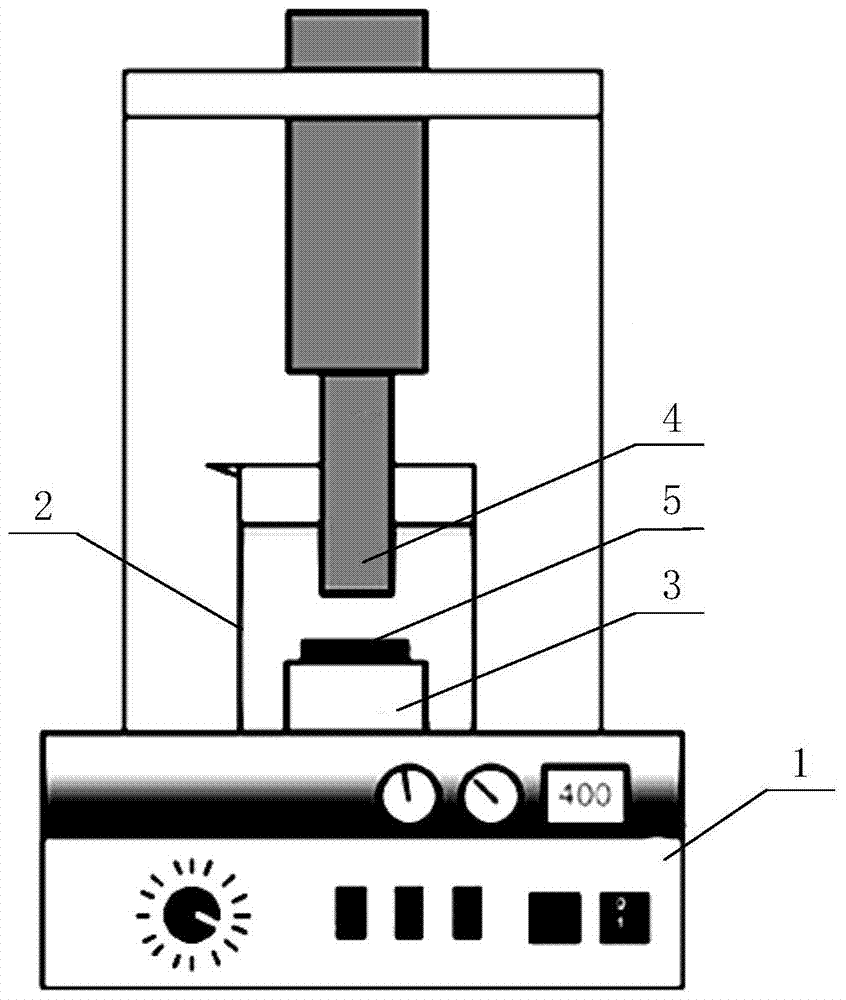

[0021] The preparation method of the iron-based nanorod provided by the present invention is described in detail below.

[0022] A method for preparing iron-based nanorods, comprising: putting polished iron materials into an aqueous dye solution, and performing ultrasonic cavitation treatment, thereby preparing iron-based nanorods on the surface of the iron materials.

[0023] Wherein, the dyeing agent is any one of methylene blue and methylene green, and the dyeing agent aqueous solution can be prepared from tap water or distilled water.

[0024] Specifically, the preparation method of the iron-based nanorods may include the following embodiments:

[0025] (1) The iron material can be pure iron, carbon steel or cast iron material, but it is better to select the iron material with a smooth and flat surface, which helps to generate iron-based nanorods on the surface of the iron material. In order to make the surface of the iron material smooth, it is best to polish the iron ma...

Embodiment 1

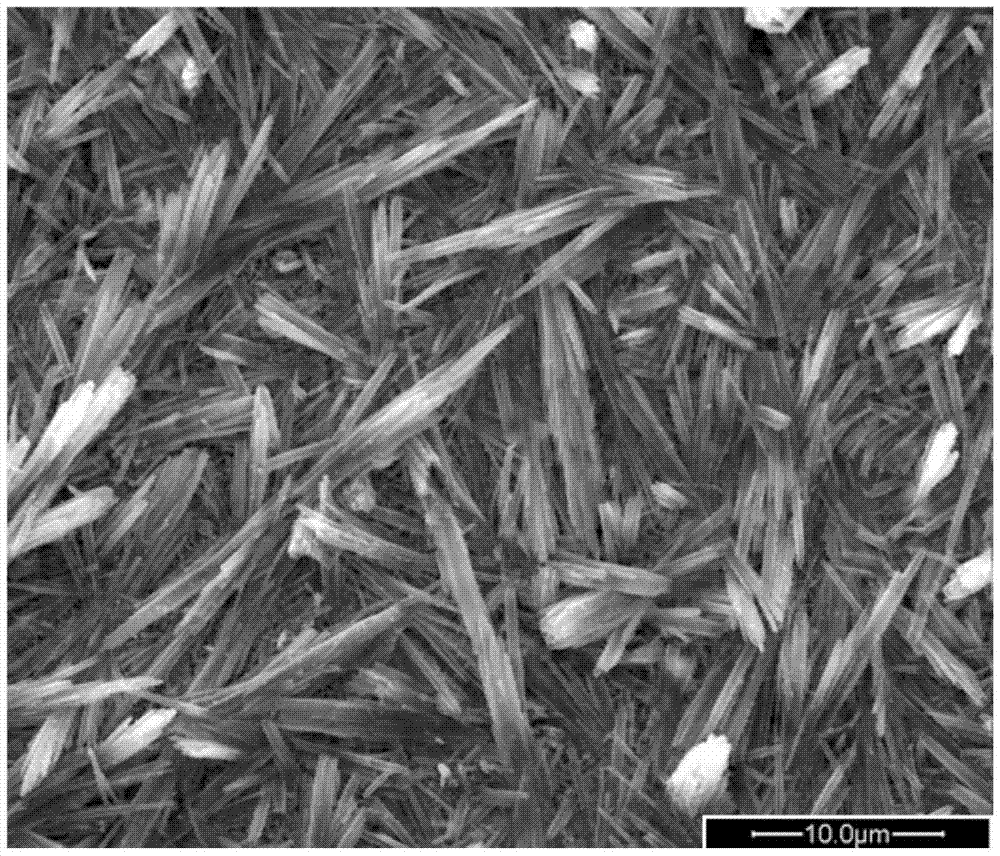

[0035] Put the polished Q235 steel block into 0.05g / L methylene blue tap water solution, and put it into the ultrasonic vibration device. The distance between the vibration head of the ultrasonic vibration device and the polished surface of the iron material is 35mm. Perform ultrasonic cavitation treatment for 25 minutes; then take out the Q235 steel block from the ultrasonic vibration device, use ethanol to perform centrifugal cleaning, and after drying, collect the surface products of the Q235 steel block, which are iron-based nanorods.

[0036] It can be known by weighing method measurement: in this embodiment 1, the average production efficiency of iron nanorods is 500g / m 2 h, the chemical properties of the prepared iron-based nanorods are stable, and there is no change in shape and composition after being stored in the atmosphere at room temperature for 3 months.

[0037] Adopt electron microscope scanning to this iron-based nanorod in the prior art, obtain as follows f...

Embodiment 2

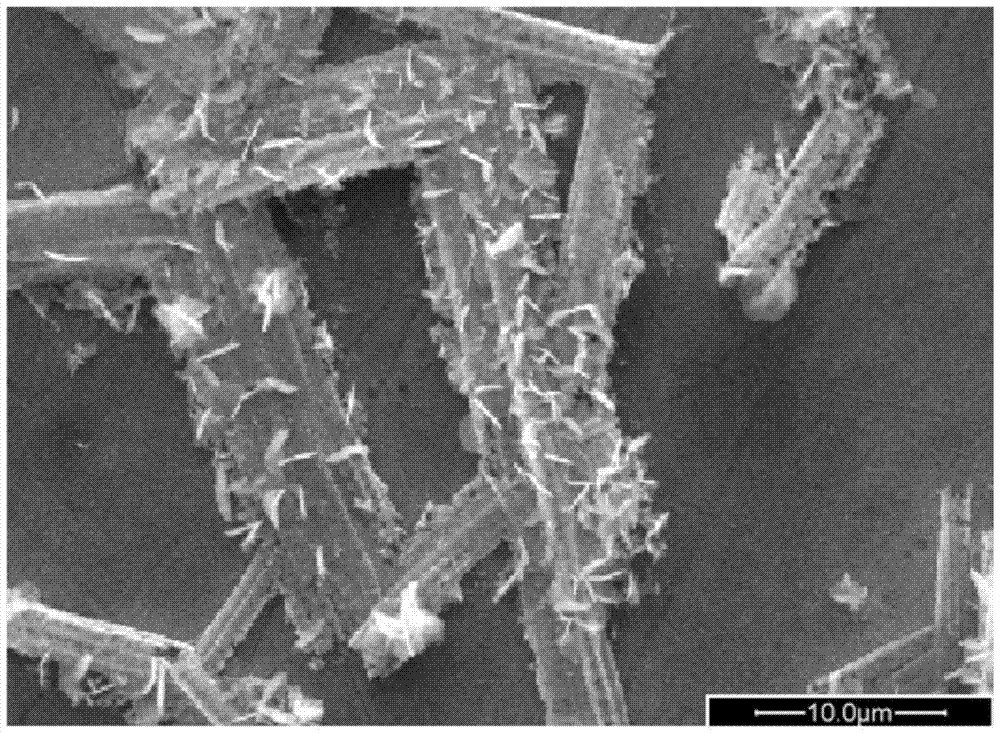

[0039] Put the polished Q235 steel block into 0.05g / L methylene blue tap water solution, and put it into the ultrasonic vibration device. The distance between the vibration head of the ultrasonic vibration device and the polished surface of the iron material is 40mm. Ultrasonic cavitation treatment was carried out for 20 minutes; then the Q235 steel block was taken out from the ultrasonic vibration device, cleaned by centrifugation with acetone, and after drying, the surface products of the Q235 steel block were collected, which were iron-based nanorods.

[0040] It can be known by weighing method measurement: in this embodiment 2, the average production efficiency of iron nanorods is 400g / m 2 h, the chemical properties of the prepared iron-based nanorods are stable, and there is no change in shape and composition after being stored in the atmosphere at room temperature for 3 months.

[0041] Adopt electron microscope scanning to this iron-based nanorod in the prior art, obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com