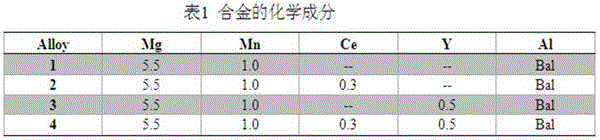

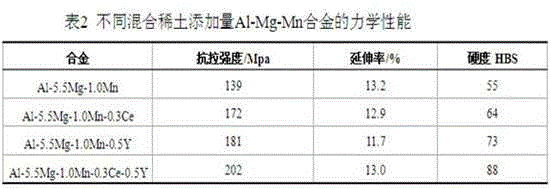

Al-Mg-Mn alloy containing rare earth elements Ce and Y, and preparation method thereof

A rare earth element and alloy technology, applied in the field of Al-Mg-Mn alloy and its preparation, can solve the problems of unsatisfactory alloy properties and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The molten materials are industrial aluminum ingots and high-purity magnesium, and Ce, Y, and Mn elements are added in the form of Al-Mn, Al-Y, and Al-Ce master alloys. The smelting uses an electric resistance furnace, which is a graphite crucible. First, put the weighed industrial pure aluminum and covering agent (NaCI, KCI) into the electric resistance furnace, melt at a temperature of 800°C, and then turn on the furnace and cool down to 600°C , Press the magnesium block with a titanium cover (magnesium has a low melting point and is not flammable when pressed), and then add the master alloy when the temperature rises to 740 ° C, stir evenly during the smelting process, and add hexachloroethane for refining and degassing. Finally, let it stand for 6 minutes, and pour it after removing the slag.

[0019]

[0020] The following items should be paid attention to when smelting:

[0021] (l) Before smelting, the raw materials should be heated to remove moisture, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com