A kind of production method of tissue paper or kitchen paper and paper preparation method thereof

A technology of kitchen paper and production method, which is applied in the field of paper production, can solve the problems of high production process cost, unfavorable market promotion, complicated research and development process, etc., achieve good results, ensure the quality of finished products, and improve the effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The hydrophobic modification of embodiment 1 kenaf core

[0038] Kenaf core has a well-developed microcavity structure, the main chemical components are cellulose, hemicellulose and lignin, and has good oil adsorption potential. Simultaneously absorb oil and water. In this embodiment, the kenaf core is hydrophobically modified to improve the oil adsorption performance of the kenaf core.

[0039] Specific steps are as follows:

[0040] 1. Preparation of kenaf core granules:

[0041] Utilize pulverizer to pulverize commercially available kenaf core, and sieve to obtain 80-100 mesh kenaf core particles;

[0042] 2. Pretreatment of kenaf core particles

[0043] Mix the crushed and sieved kenaf core particles with 40g / L NaOH solution, the mass ratio of the NaOH solution to the kenaf core particles is 15:1, shake at a constant temperature at 40°C for 6h, and then neutralize it to pH with hydrochloric acid =7, after suction filtration, washing and drying, ball milling for...

Embodiment 2

[0046] Embodiment 2 comprises the preparation of the paper of modified kenaf core

[0047] The modified kenaf has good adsorption performance for oil stains. In this example, the paper with good oil stain adsorption performance is prepared by adding modified kenaf particles to paper.

[0048] Specific steps are as follows:

[0049] (1) 20 parts of coniferous fiber, 35 parts of bamboo fiber, and 25 parts of bagasse fiber are crushed into wood pulp through a pulper, and the slag is removed through a high-concentration slag removal system, and impurities are removed by a coarse sieve. Sieve and concentrate to obtain fiber wood pulp;

[0050] (2) Put the fiber wood pulp in the pulper, add water to adjust the wood pulp concentration to be 6.0wt%, and after 10 minutes of disintegration, the resulting pulped material will be disentangled by the fiber disintegration machine, and then beaten by a beater to obtain Fiber wood pulp after tapping, the beating degree is 32°SR;

[0051] (...

Embodiment 3

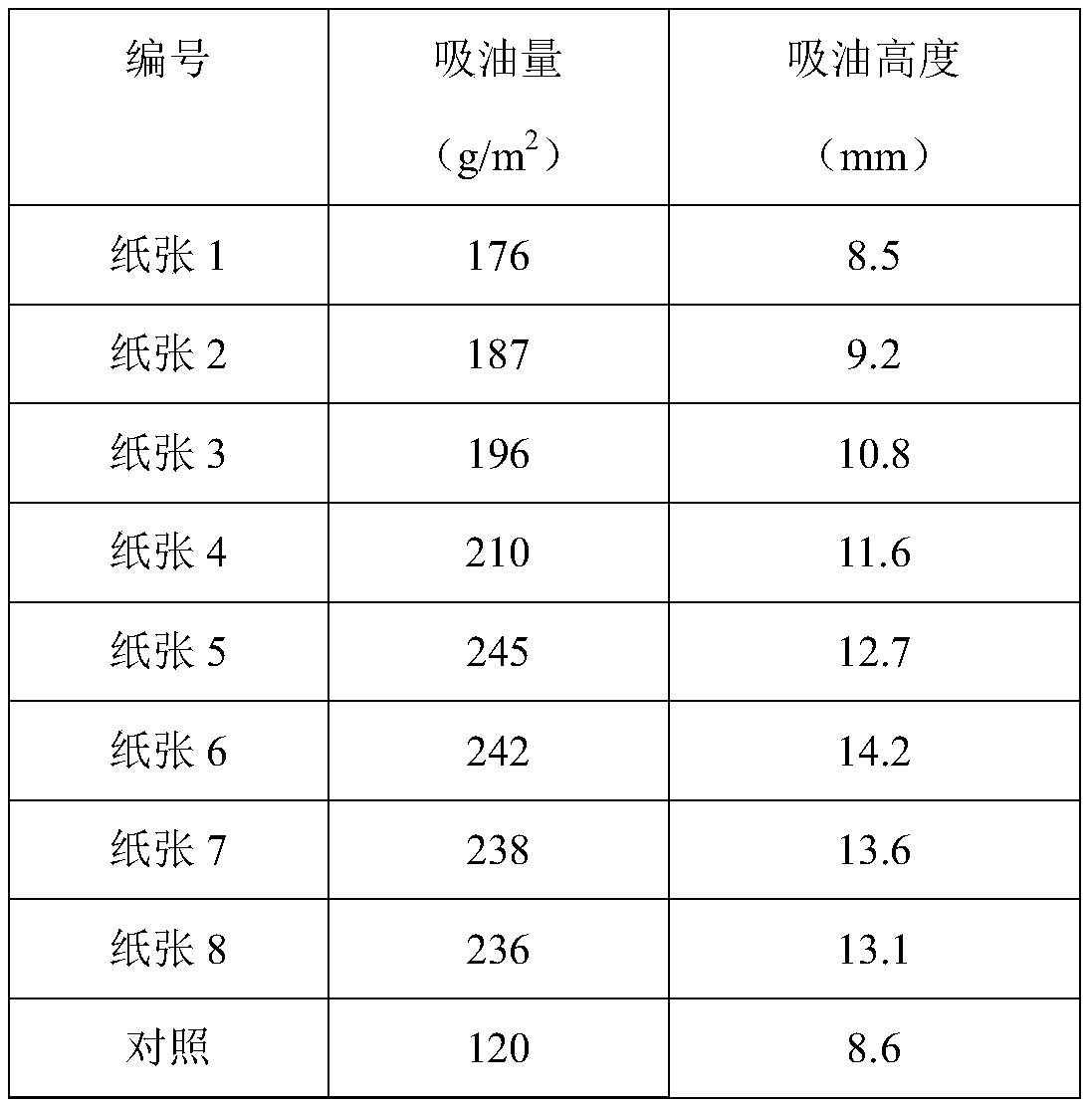

[0054] Embodiment 3: the influence of the addition amount of kenaf core on paper oil-absorbing performance

[0055] In order to explore the impact of the addition of different kenaf cores on the oil-absorbing performance of paper, and strive to find the most suitable addition of kenaf cores, the present embodiment adopts the following experimental design:

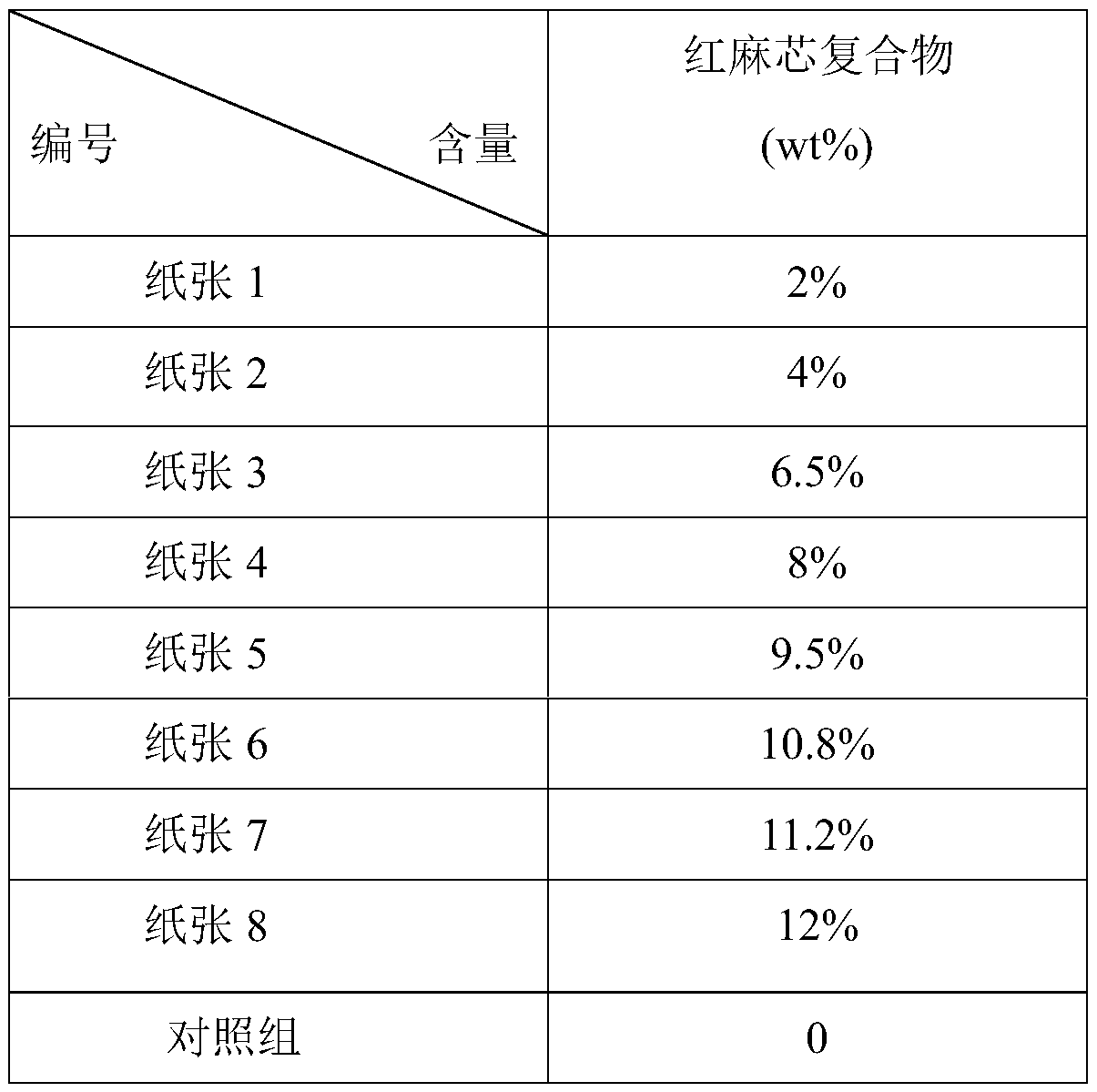

[0056] In the preparation of paper, the addition amount of different kenaf core mixtures is adopted, and the specific addition amount of kenaf core mixture is as shown in Table 1,

[0057] The addition amount of kenaf core compound in table 1 paper

[0058]

[0059] For the above-mentioned different concentrations, three parallel experiments were set up for each group, and the specific steps were as follows:

[0060] 1. Paper Preparation

[0061] (1) 20 parts of coniferous fiber, 35 parts of bamboo fiber, and 25 parts of bagasse fiber are crushed into wood pulp through a pulper, and the slag is removed through a high-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com