High modulus glass fiber

A technology of glass fiber and high modulus, which is applied in the field of glass fiber and high modulus glass fiber, can solve the problems of high processing cost that cannot realize industrialization, close molding temperature and liquidus temperature, high fiber molding temperature, etc., to ensure mechanical Effects of performance and chemical stability, reduction of glass density, improvement of tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention has no special restrictions on the preparation method of the glass fiber, and it is preferably produced by the tank kiln method. Specifically, it can be prepared according to the following method:

[0037] Mix all kinds of raw materials uniformly and put them into the kiln. After melting, clarification and homogenization, the glass liquid is obtained;

[0038] The glass fiber is obtained by cooling, flowing out and drawing the glass liquid.

[0039] The present invention first mixes various raw materials in a mixing tank, and after they are evenly mixed, they are transported to the kiln silo; then the kiln silo puts the mixed materials into the kiln, and melts them under the conditions of 1400-1650°C. Clarify and homogenize to obtain molten glass;

[0040] Cooling the glass liquid to 1250-1350°C, flowing out through the platinum drain plate, and drawing into a glass filament with a diameter of 3-25um under the traction of a wire drawing machine;

[0041] Sp...

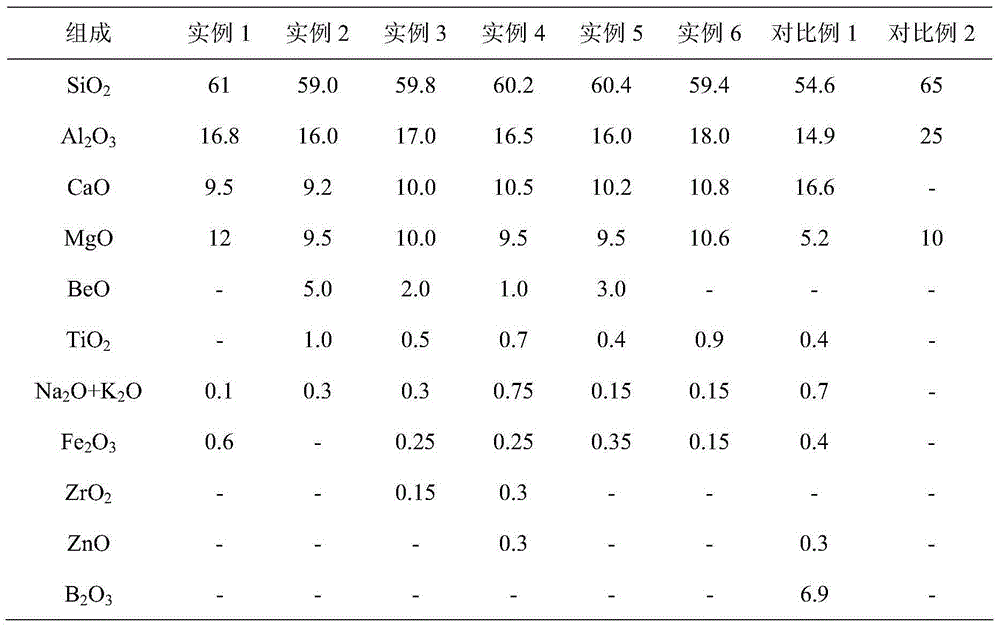

Embodiment 1

[0045] Select SiO according to the parameters of Example 1 shown in Table 1. 2 , 61%; Al 2 O 3 , 16.8%; CaO, 9.5%; MgO, 12%; Na 2 O+K 2 O, 0.1% and Fe 2 O 3 , 0.6% as glass raw material, and calculate the amount of each raw material;

[0046] Then weigh the required raw materials in proportion and transport them all to the mixing tank. After the mixing is uniform, the mixture is transported to the kiln silo;

[0047] Put the mixture in the silo of the tank kiln into the tank kiln. In the tank kiln, the mixture is gradually melted into molten glass at a high temperature above 1400℃. After clarification and homogenization, the stable and high-quality molten glass enters the wire drawing operation channel ;

[0048] After cooling the glass liquid in the wire drawing channel to a suitable temperature, it flows out through the platinum drain plate and is quickly drawn by the wire drawing machine into a glass wire with a diameter of 3-25μm;

[0049] The glass filaments are spray-cooled and ...

Embodiment 2

[0051] Select SiO according to the formula in Example 2 in Table 1 2 , 59.0%; Al 2 O 3 , 16.0%; CaO, 9.2%; MgO, 9.5%; BeO, 5.0%; TiO 2 , 1.0% and Na 2 O+K 2 O was used as the glass raw material, and the high modulus glass fiber was prepared according to the method in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus | aaaaa | aaaaa |

| Specific modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com