Annealing method of injection bottles made from glass tubes

A technology for injection bottles and glass bottles, which is applied in the field of glass bottle annealing, can solve problems such as unstable product quality control, influence on proficiency, and low work efficiency, and achieve obvious energy-saving effects, good heat preservation performance, and improved quality consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

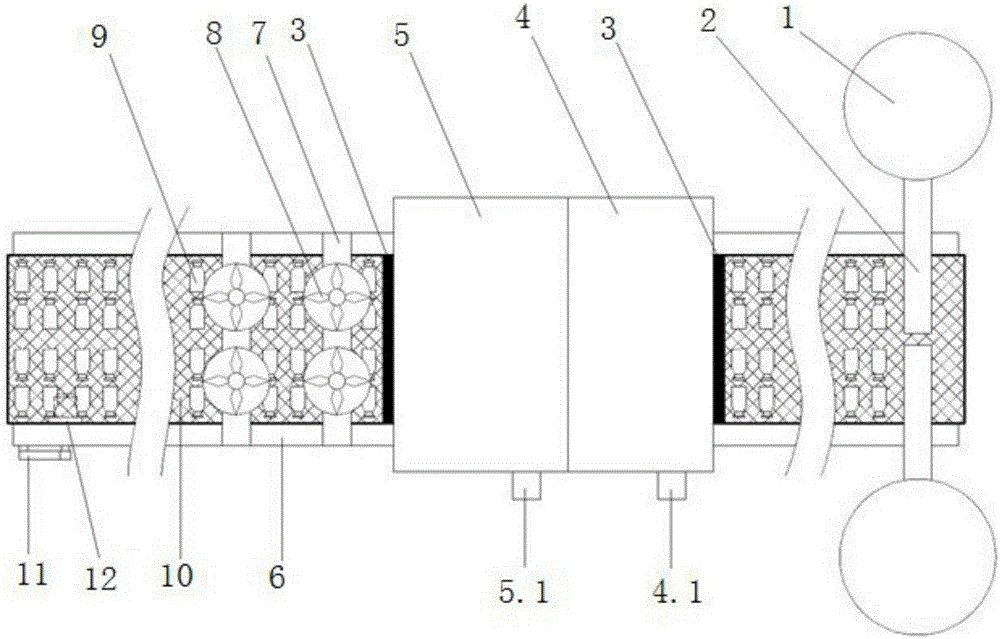

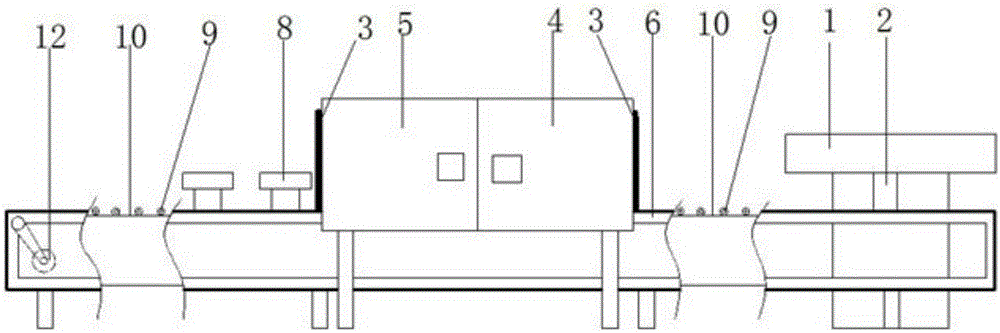

[0021] Such as figure 1 , figure 2 As shown, the annealing method for glass tube injection bottles includes the following steps: the glass bottle rolls from the bottle making machine 1 through the blanking chute 2 onto the mesh conveyor belt 10, and since the mesh conveyor belt 10 is in a low-speed conveying state, the glass bottle Evenly scattered on the mesh conveyor belt 10; the mesh conveyor belt 10 slowly transports the glass bottles to the annealing furnace, passes through the temperature control room 4 for heating at a temperature of 600°C, and passes through the holding room 5 for heating at a temperature of 550°C heat preservation annealing, since the running speed of the mesh conveyor belt 10 is 0.105m / min and the length of the annealing furnace is 2.1m, it can ensure that the time of the glass bottle in the temperature control room 4 and the heat preservation room 5 is long enough, up to 20min, Meet the needs of heating and annealing;

[0022] The mesh conveyor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com