FeS and Fe0 composite and preparation method and application thereof

A composite material and nanotechnology, applied in the field of chemical materials, can solve the problems of complex operation, long preparation time, waste of raw materials, etc., and achieve the effect of simple preparation process, environmental protection and feasible reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

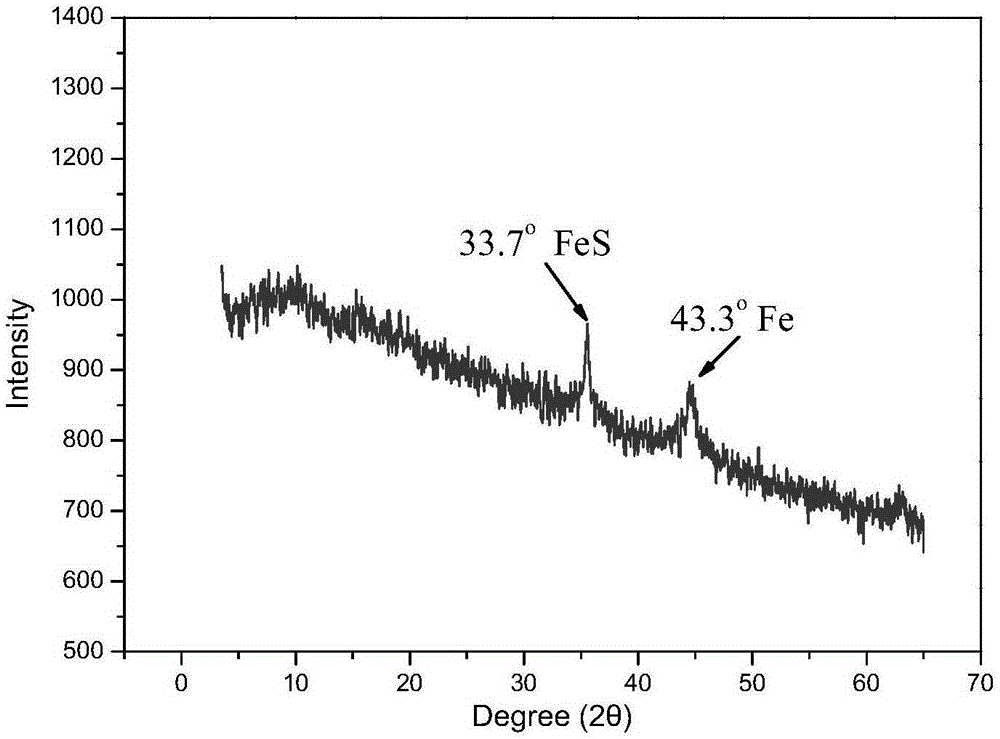

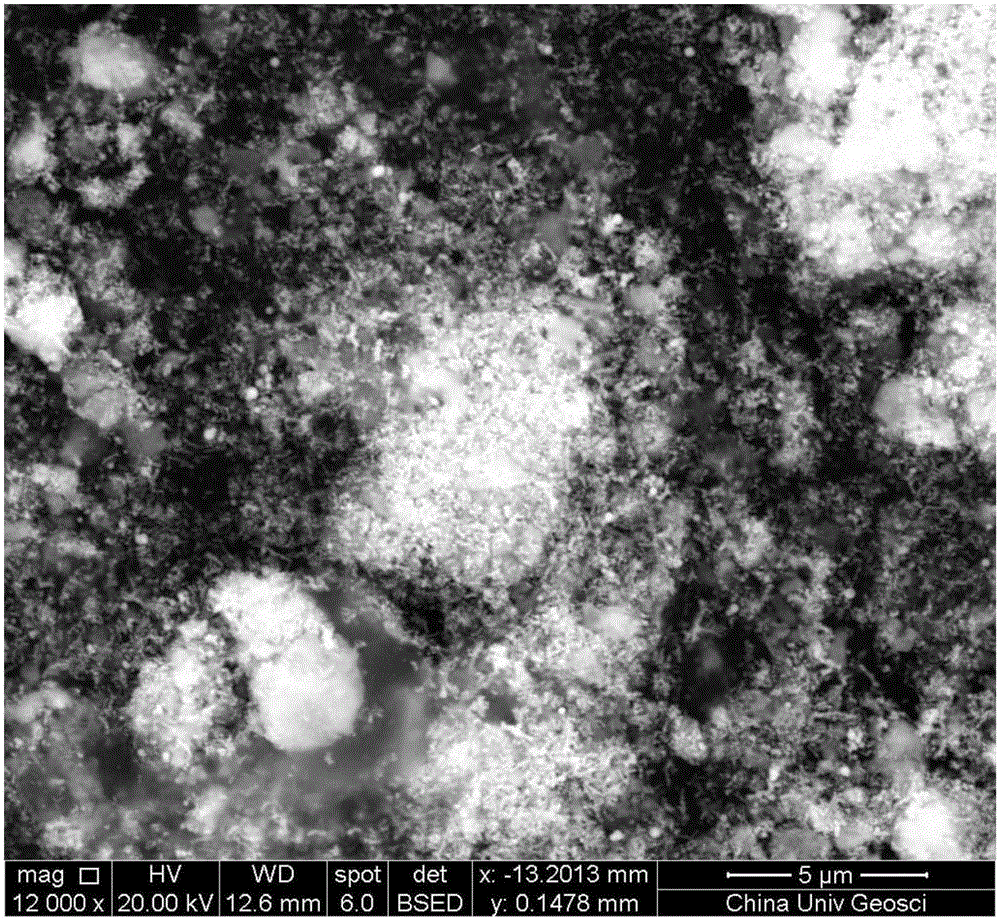

Image

Examples

Embodiment 1

[0037] A FeS / Fe 0 A method for preparing a composite material, comprising the steps of:

[0038] (1) Weigh 0.018mol of FeSO 4 ·7H 2 O (iron salt) and 0.036mol of NaBH 4 (strong reducing agent), respectively dissolved in anaerobic water to obtain NaBH 4 solution and FeSO 4 solution, in N 2 Under the protection of a closed environment, the NaBH 4 The solution was added dropwise to FeSO 4 Solution, mechanically stirred, and fully reacted for 20 minutes to form black nano-sized zero-valent iron particles;

[0039] (2) Magnetically separate the nano-zero-valent iron particles in the solution, wash them three times with anaerobic water and absolute ethanol, and then disperse the nano-zero-valent iron evenly in 100mL of anaerobic water to obtain a nano-zero-valent iron suspension;

[0040] (3) Weigh 0.002M FeSO 4 ·7H 2 O (ferrous salt) and Na 2 S, also dissolved in anaerobic water at a volume ratio of 1:1 to obtain FeSO 4 solution and Na 2 S solution, FeSO 4 The solutio...

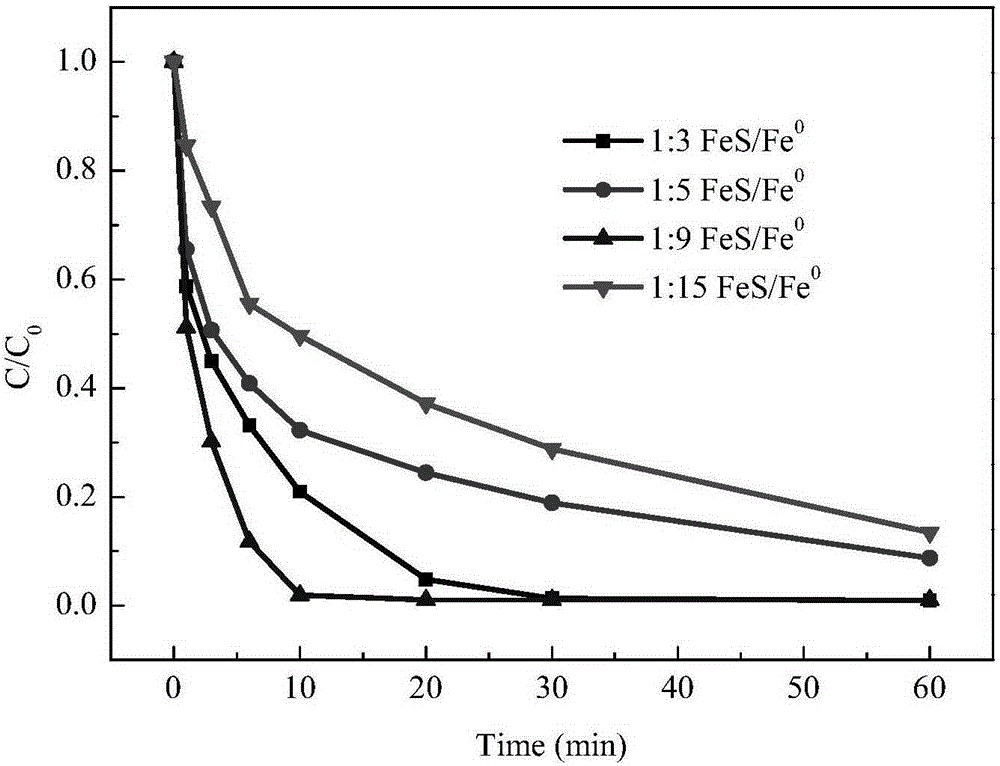

Embodiment 2

[0044] This embodiment prepares FeS / Fe 0 The method of composite material is roughly identical with embodiment 1, and difference is: (1) choose ferric sulfate as the iron salt described in step (1); Choose potassium borohydride as the strong reducing agent described in step (1); Choose chloride Ferrous iron is as described ferrous salt of step (3); Select K for use 2 S replaces Na in step (3) 2 S; (2) the molar ratio of the ferric sulfate and potassium borohydride is 1:3; the ferrous chloride and K 2 The molar mass ratio of S is 1:1; the molar mass ratio of the iron salt described in step (1) to the ferrous salt described in step (3) is 3:1.

[0045] The FeS / Fe that this embodiment prepares 0 FeS and Fe in composites 0 The molar ratio is 1:3.

Embodiment 3

[0047] This embodiment prepares FeS / Fe 0 The method of composite material is roughly identical with embodiment 1, and difference is: (1) choose ferrous nitrate as the iron salt described in step (1); Choose potassium borohydride and sodium borohydride by 1:1 combination as step ( 1) described strong reductant; Choose ferrous nitrate as the ferrous salt described in step (3); (2) the molar ratio of described ferrous nitrate and strong reductant is 1:2; Described ferrous nitrate and Na 2 The molar mass ratio of S is 1:1; the molar mass ratio of the iron salt described in step (1) to the ferrous salt described in step (3) is 5:1.

[0048] The FeS / Fe that this embodiment prepares 0 FeS and Fe in composites 0 The molar ratio is 1:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com