Polyurethane foam supported liver/graphene/ titanium dioxide nano particle composite material, preparation method thereof and application thereof

A technology of polyurethane sponge and titanium dioxide, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, other chemical processes, etc., can solve the problem of weakening the actual processing capacity of photocatalysis, difficulty in recycling, secondary pollution, etc. problems, to achieve the effect of ensuring stability and reusability, cheap raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

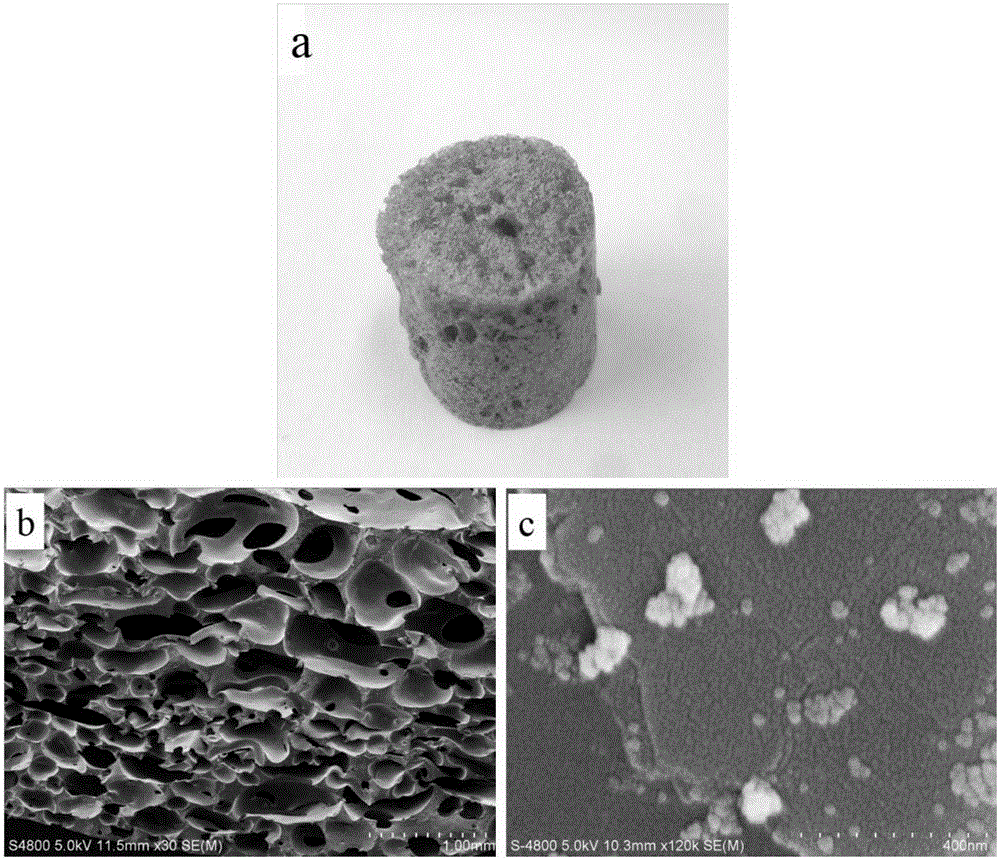

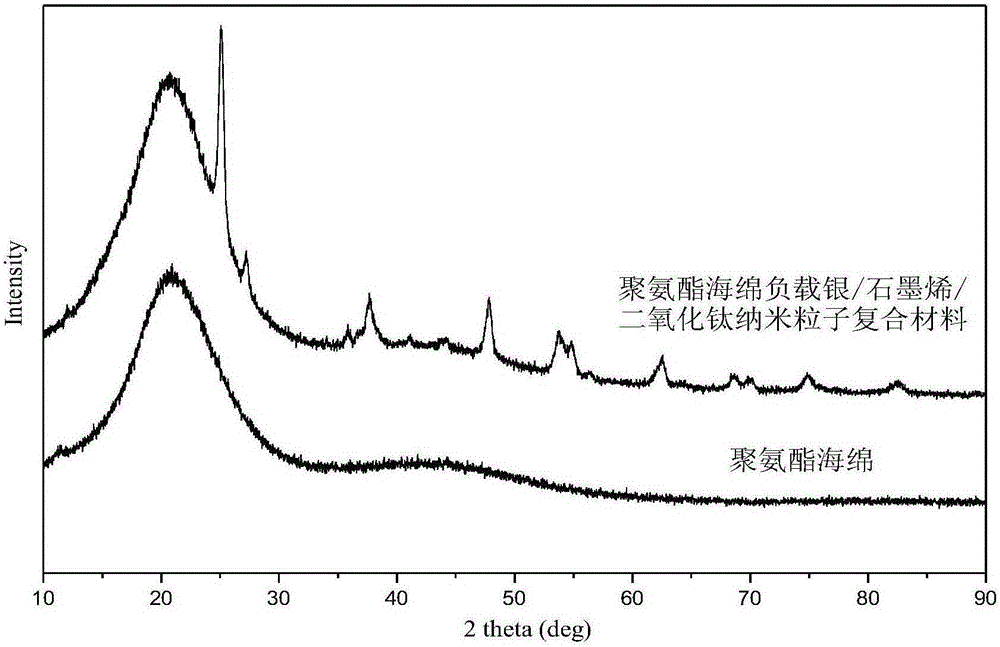

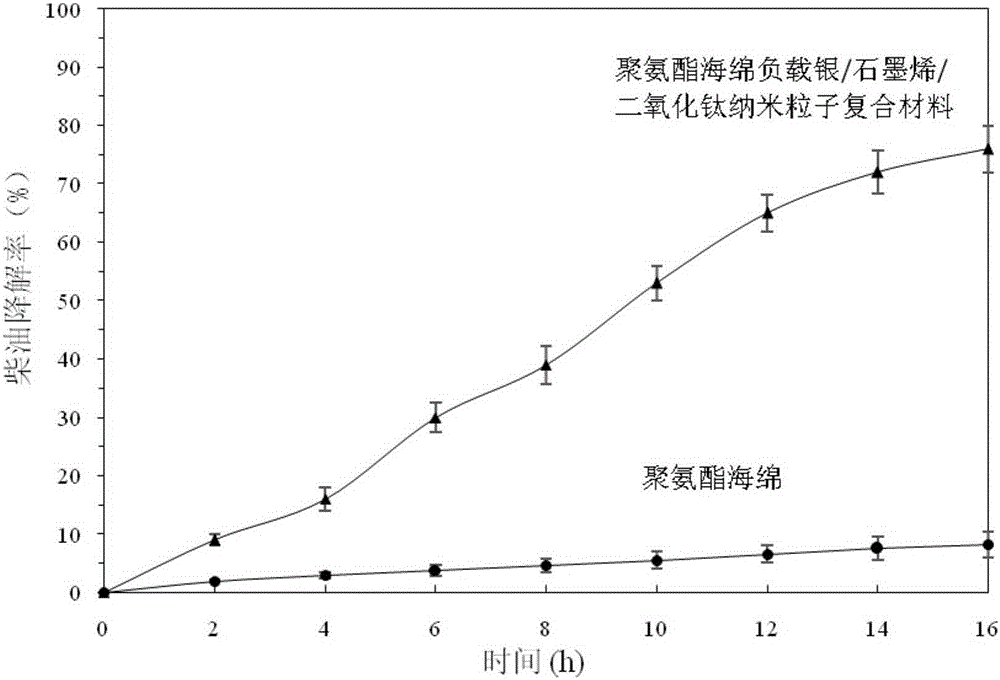

Image

Examples

Embodiment 1

[0030] (1) Preparation of graphite oxide: add 1 g of graphite with a purity of 99.5% to a mixed solution consisting of 90ml of concentrated sulfuric acid with a mass fraction of 98% and 25ml of concentrated nitric acid with a mass fraction of 65%, and place in an ice-water mixing bath (temperature control (below 4°C) and stirred for 20min. Then slowly add 6g of potassium permanganate and stir for 1h. Then the mixed solution was heated to 85°C for 30min, then 10ml of hydrogen peroxide with a mass fraction of 30% was added, stirred for 10min, the mixture was suction filtered, and finally the solid was repeatedly washed with 100ml of dilute hydrochloric acid and 150ml of deionized water. After washing three times, the solid matter was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0031](2) Preparation of graphene / titanium dioxide nanoparticles: ultrasonically disperse 0.025g of graphite oxide in a mixed solution of 60ml of distilled water and 30ml of ...

Embodiment 2

[0036] (1) Preparation of graphite oxide: add 1 g of graphite with a purity of 99.5% to a mixed solution consisting of 90ml of concentrated sulfuric acid with a mass fraction of 98% and 25ml of concentrated nitric acid with a mass fraction of 65%, and place in an ice-water mixing bath (temperature control (below 4°C) and stir for 20min. Then slowly add 6g of potassium permanganate and stir for 1h. Then the mixed solution was heated to 85°C for 30min, then 10ml of hydrogen peroxide with a mass fraction of 30% was added, stirred for 10min, the mixture was suction filtered, and finally the solid was repeatedly washed with 100ml of dilute hydrochloric acid and 150ml of deionized water. After washing three times, the solid matter was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0037] (2) Preparation of graphene / titanium dioxide nanoparticles: ultrasonically disperse 0.025g of graphite oxide in a mixed solution of 60ml of distilled water and 30ml of fo...

Embodiment 3

[0041] (1) Preparation of graphite oxide: add 1 g of graphite with a purity of 99.5% to a mixed solution consisting of 90ml of concentrated sulfuric acid with a mass fraction of 98% and 25ml of concentrated nitric acid with a mass fraction of 65%, and place in an ice-water mixing bath (temperature control (below 4°C) and stir for 20min. Then slowly add 6g of potassium permanganate and stir for 1h. Then the mixed solution was heated to 85°C for 30min, then 10ml of hydrogen peroxide with a mass fraction of 30% was added, stirred for 10min, the mixture was suction filtered, and finally the solid was repeatedly washed with 100ml of dilute hydrochloric acid and 150ml of deionized water. After washing three times, the solid matter was dried in a vacuum oven at 60° C. for 12 hours to obtain graphite oxide.

[0042] (2) Preparation of graphene / titanium dioxide nanoparticles: ultrasonically disperse 0.025g of graphite oxide in a mixed solution of 60ml of distilled water and 30ml of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com