Preparation method of Maillard reaction products of ulva fasciata polysaccharide and gelatin peptide

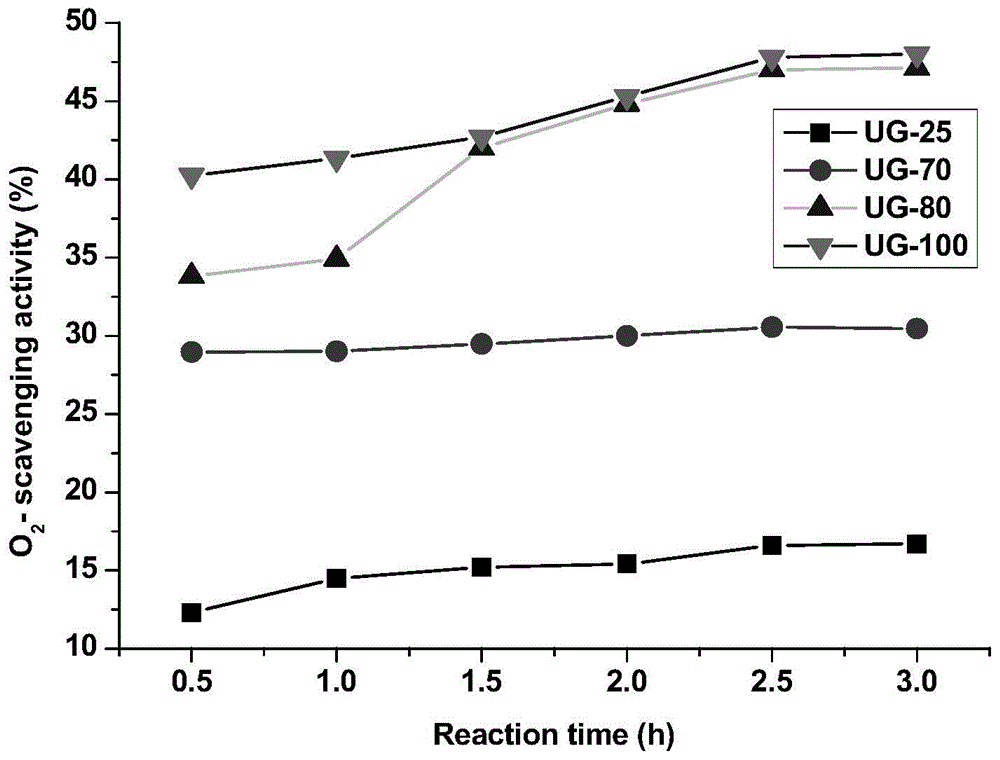

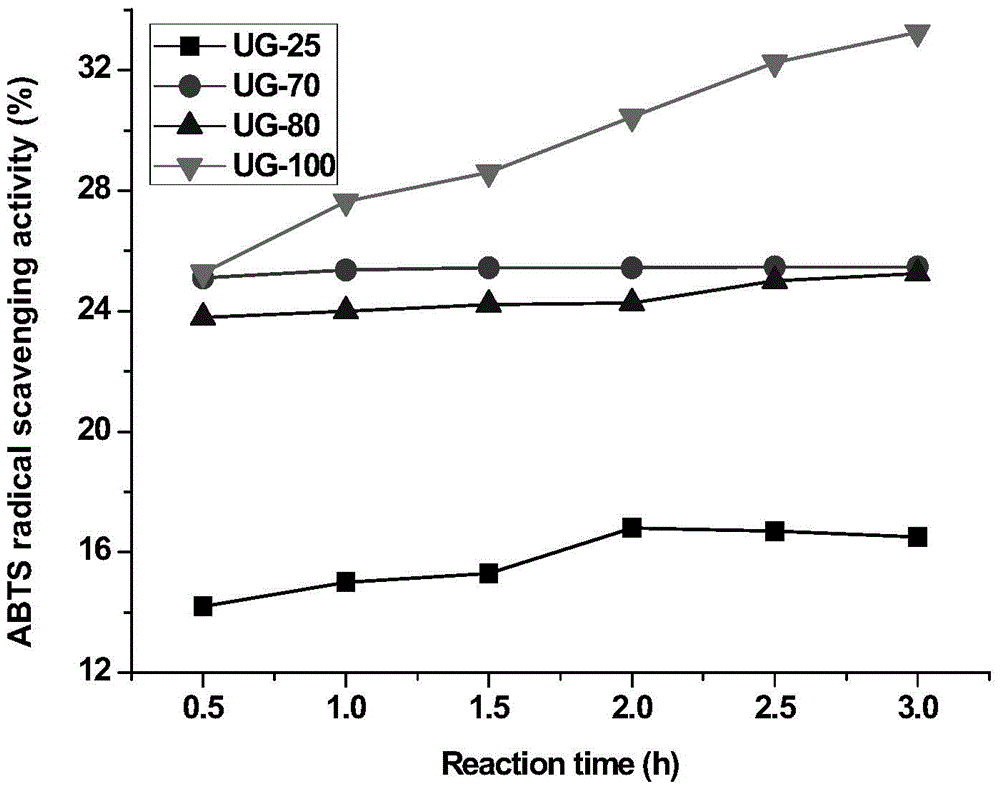

A technology of Ulva schistus and polysaccharides, which is applied in the field of preparation of Ulva sliver polysaccharides and gelatin peptide Maillard reaction products, can solve the problems of low added value of products, waste of resources, etc., and achieve the effect of improving the antioxidant capacity in vitro

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Extraction and separation of polysaccharides from Ulva sliver

[0035] Raw material pretreatment: Ulva splinters were rinsed repeatedly with fresh water, dried in the shade, soaked overnight in 95% alcohol, dried in an oven at 60°C, crushed, passed through an 80-mesh sieve, and stored in a desiccator for later use.

[0036] Microwave-assisted extraction process: take an appropriate amount of algae powder, add distilled water according to a certain ratio of material to liquid, and perform microwave-assisted extraction according to the set parameters: microwave power 400W, extraction time 8min, liquid-to-solid ratio 25mL / g, under this parameter, the extraction rate up to 16.37%. After the extraction was completed, cool and stand for 0.5 h, and then refrigerated and centrifuged at 10,000 rpm and 4°C for 10 min to obtain supernatant and precipitate. Take the supernatant, concentrate it to 2 times the concentration by rotary evaporation, add 95% ethanol solution to make ...

Embodiment 3

[0048] 1. Determination of scavenging hydroxyl radical·OH by Maillard reaction product

[0049] Pipette 0.8mL of each spare sample solution for Maillard reaction, add 2mL 2mmol / L FeSO4 solution, 1mL 2mmol / L sodium salicylate and 1ml 0.1% H 2 o 2 , the blank control tube replaced the UG sample solution with distilled water, and the sample control tube replaced the sodium salicylate solution with distilled water, in a constant temperature water bath for 1h (37°C), let it stand for cooling, and measured its absorbance at a wavelength of 510nm.

[0050] R%=[A 0 -(A i -A j )] / A 0 ×100%

[0051] In the formula: A 0 、A i 、A j Represent the absorbance of blank control, sample and sample control, respectively.

[0052] Hydroxyl free radicals are one of the most active free radicals in reactive oxygen species, and are also the most toxic free radicals in organisms, which can directly damage various biofilms, cause a variety of diseases and endanger organisms. The experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com