Degradable biomedical mg-nd-sr magnesium alloy and its preparation method and application

A biomedical and magnesium alloy technology, applied in the field of biomedical implant materials, can solve problems such as neurotoxicity, achieve good biocompatibility, reduce content, and require low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

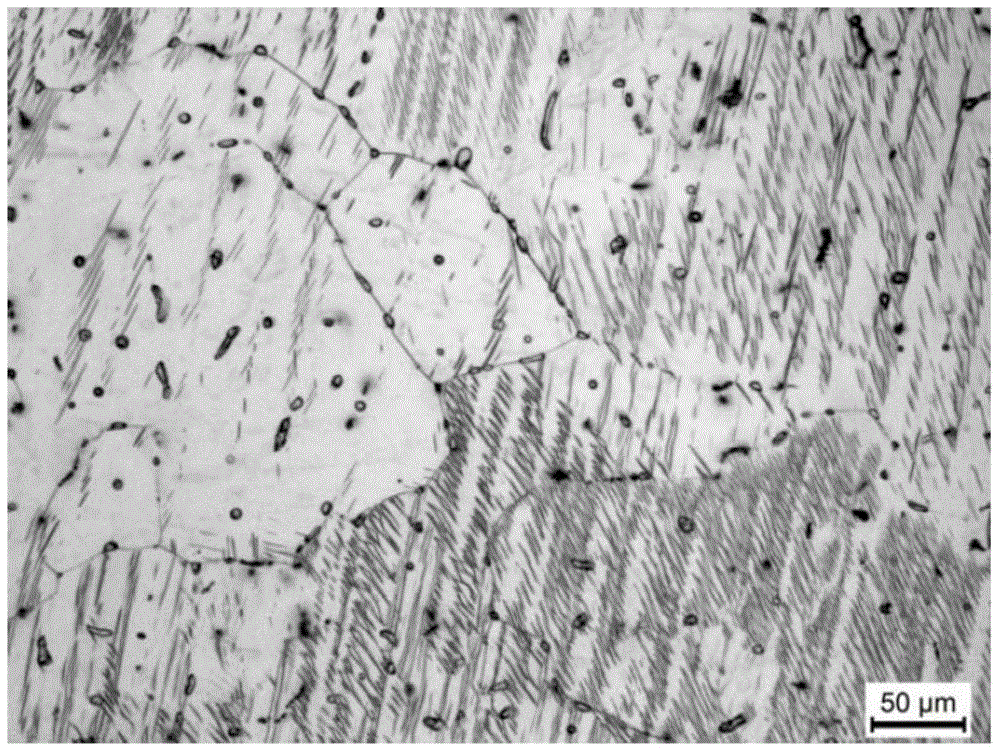

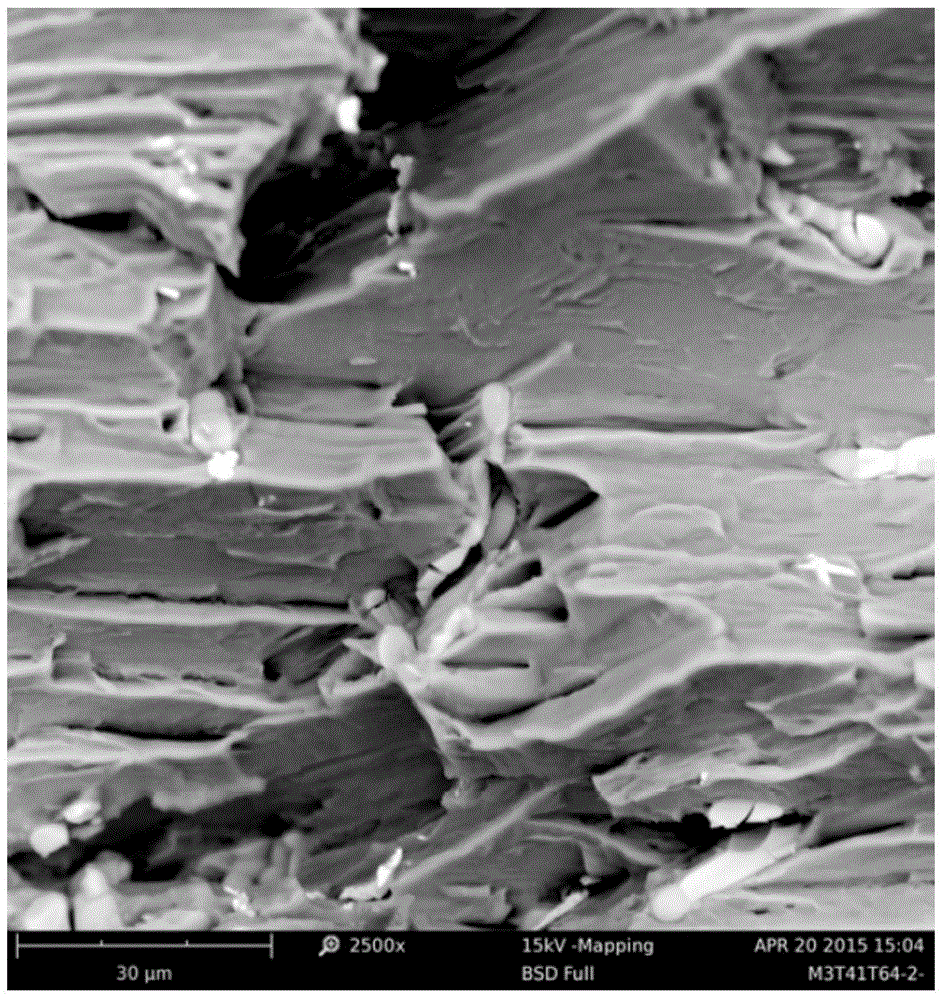

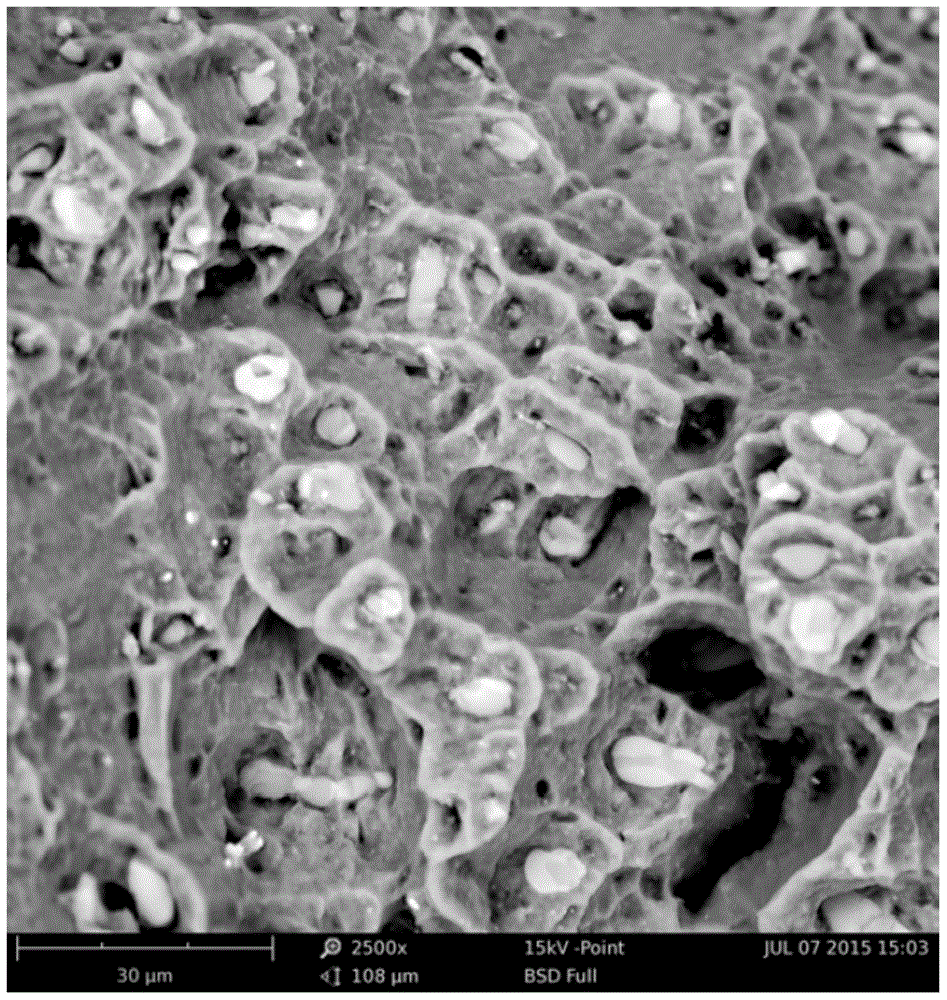

Image

Examples

Embodiment 1

[0043] The preparation of the Mg-1.91%Nd-0.27%Sr magnesium alloy of the present embodiment, the specific preparation process is:

[0044] (1) With the high-purity magnesium ingot, the Mg-Nd master alloy whose mass percentage content of Nd is 30%, and the Mg-Sr master alloy whose mass percentage content of Sr is 25% as raw materials, according to the Nd and Sr master alloys in the two master alloys The weight percentage composition is by weight percentage 1.91%Nd, 0.27%Sr, all the other are Mg and carry out material preparation;

[0045] (2) Sprinkle a certain amount of RJ-5 flux on the wall and bottom of the reaction vessel in advance, preheat the reaction vessel to about 400°C, add high-purity magnesium ingots and raise the temperature to 720°C, after the magnesium ingots are melted, heat up to 750°C and add Mg in turn -Nd and Mg-Sr master alloys, after the Mg-Nd master alloys are completely melted, add Mg-Sr master alloys, and keep stirring to mix them evenly to obtain alloy...

Embodiment 2

[0056] The preparation of the Mg-1.48%Nd-2.49%Sr magnesium alloy of the present embodiment, the specific preparation process is:

[0057] (1) With the high-purity magnesium ingot, the Mg-Nd master alloy whose mass percentage content of Nd is 30%, and the Mg-Sr master alloy whose mass percentage content of Sr is 25% as raw materials, according to the Nd and Sr master alloys in the two master alloys The weight percentage composition is by weight percentage 1.48%Nd, 2.49%Sr, all the other are Mg and carry out material preparation;

[0058] (2) Sprinkle a certain amount of RJ-5 flux on the wall and bottom of the reaction vessel in advance, preheat the reaction vessel to about 400°C, add high-purity magnesium ingots and raise the temperature to 710°C, after the magnesium ingots melt, heat up to 750°C and add Mg in turn -Nd and Mg-Sr master alloys, after the Mg-Nd master alloys are completely melted, add Mg-Sr master alloys, and keep stirring to mix them evenly to obtain alloy melts...

Embodiment 3

[0068] The preparation of the Mg-2.07%Nd-0.24%Sr magnesium alloy of the present embodiment, the specific preparation process is:

[0069] (1) With the high-purity magnesium ingot, the Mg-Nd master alloy whose mass percentage content of Nd is 30%, and the Mg-Sr master alloy whose mass percentage content of Sr is 25% as raw materials, according to the Nd and Sr master alloys in the two master alloys The weight percentage composition is by weight percentage 2.07%Nd, 0.24%Sr, all the other are Mg and carry out material preparation;

[0070] (2) Sprinkle a certain amount of RJ-5 flux on the wall and bottom of the reaction vessel in advance, preheat the reaction vessel to about 400°C, add high-purity magnesium ingots and raise the temperature to 720°C, after the magnesium ingots are melted, heat up to 740°C and add Mg in turn -Nd and Mg-Sr master alloys, after the Mg-Nd master alloys are completely melted, add Mg-Sr master alloys, and keep stirring to mix them evenly to obtain alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com