Process and device for acylation reaction of acetaminophen

A technique for the acylation reaction of acetaminophen and acetaminophen, which is applied in the field of pharmaceutical preparations, can solve the problems of high concentration of acetic acid, high reaction temperature, and long reaction time, and achieve the reduction of waste acid evaporation, lower reaction temperature, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

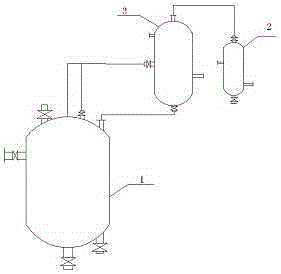

Image

Examples

Embodiment 1

[0030] Paracetamol acylation process of the present invention is as follows:

[0031] (1) Preparation of materials: Add 1200Kg of para-aminophenol, 2400L of paracetamol mother liquor and 1000Kg of glacial acetic acid into the reactor 1;

[0032] Paracetamol mother liquor comprises the component of following parts by weight:

[0033] 9~11 parts of acetaminophen

[0034] p-Aminophenol≤0.02 parts

[0035] 53~54 parts of acetic acid

[0036] 35~37 parts of water.

[0037] (2) Acylation reaction: raise the temperature of reactor 1 to 108°C to carry out the reaction;

[0038] (3) Distillation of acetic acid: the acid evaporated from the reaction kettle 1 enters the rectification tower 2, the temperature of the bottom of the rectification tower 2 is 108°C, the temperature at the top of the tower is 90°C, and the reflux ratio is 1:9;

[0039] (4) Recovery of dilute acid: dilute acid evaporated from rectification tower 2 enters condenser 3 and condenses to become waste dilute acid...

Embodiment 2

[0047] Paracetamol acylation process of the present invention is as follows:

[0048] (1) Preparation of materials:

[0049] Add 1200Kg of para-aminophenol, 2400L of paracetamol mother liquor and 1000Kg of glacial acetic acid in the reaction kettle 1

[0050] Paracetamol mother liquor comprises the component of following parts by weight:

[0051] 9~11 parts of acetaminophen

[0052] p-Aminophenol≤0.02 parts

[0053] 53~54 parts of acetic acid

[0054] 35~37 parts of water.

[0055] (2) Acylation reaction: raise the temperature of reactor 1 to 132°C to carry out the reaction;

[0056] (3) Distillation of acetic acid: the acid evaporated from the reaction kettle 1 enters the rectification tower 2, the temperature of the bottom of the rectification tower 2 is 108°C, the temperature at the top of the tower is 90°C, and the reflux ratio is 1:9;

[0057] (4) Recovery of dilute acid: dilute acid evaporated from rectification tower 2 enters condenser 3 and condenses to become wa...

Embodiment 3

[0065] A device for realizing the process described in Example 1 and Example 2 consists of a reactor 1, a rectifying column 2 and a condenser 3 connected in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com