An internal circulation enhanced fully mixed flow anaerobic reactor

An anaerobic reactor and fully mixed flow technology, which is applied in the direction of anaerobic digestion and treatment, can solve the problems of high energy consumption and unsatisfactory mixing effect, and achieve the effects of reducing interference, stabilizing discharge, and small height-to-diameter ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

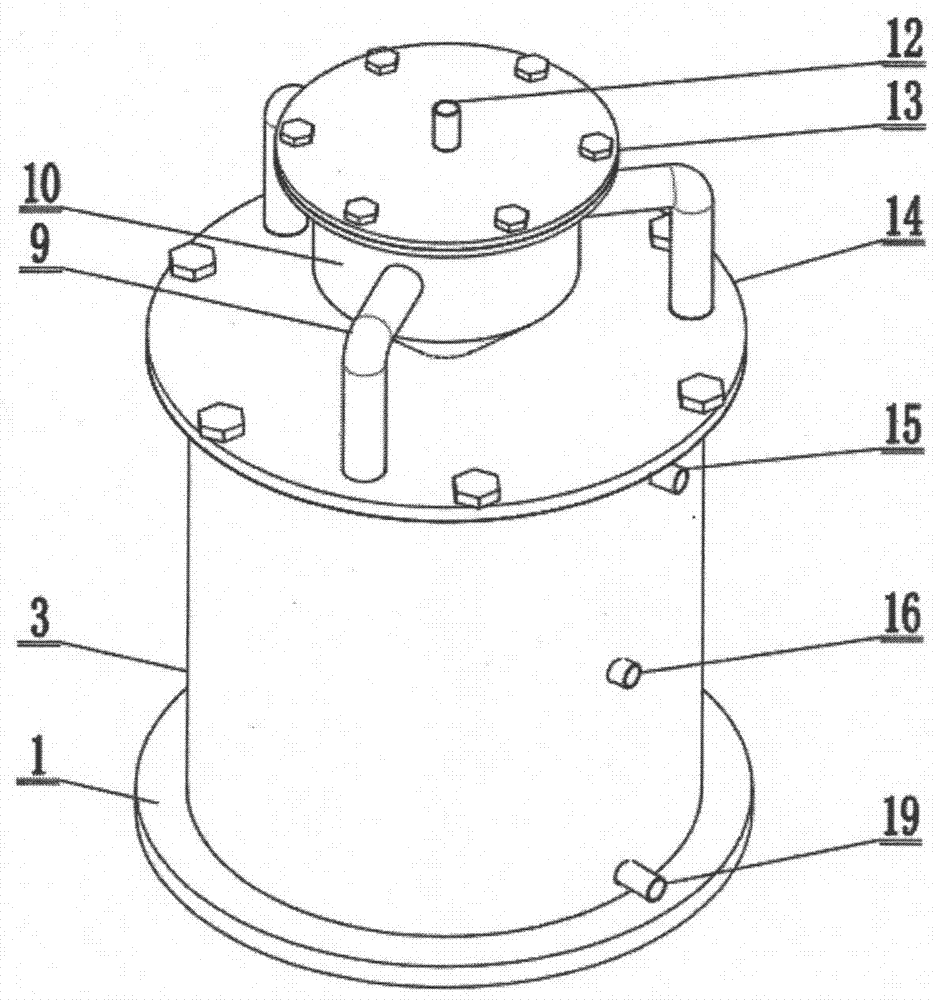

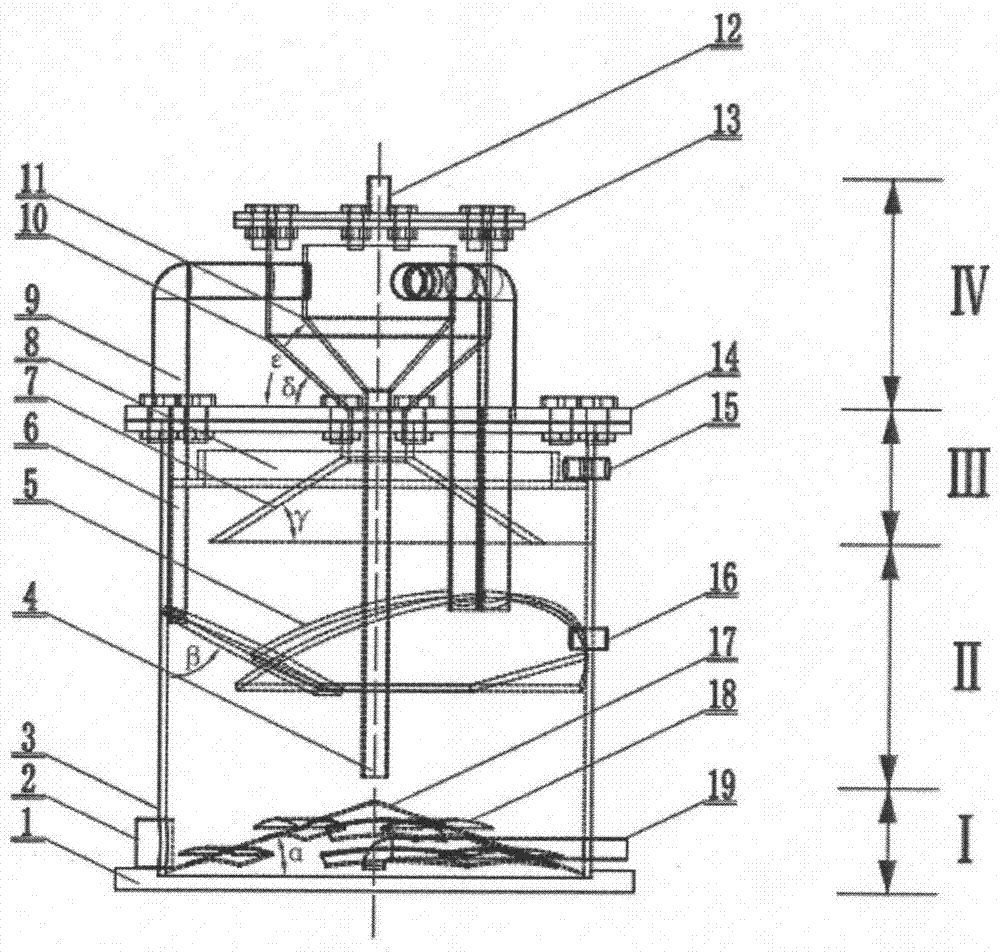

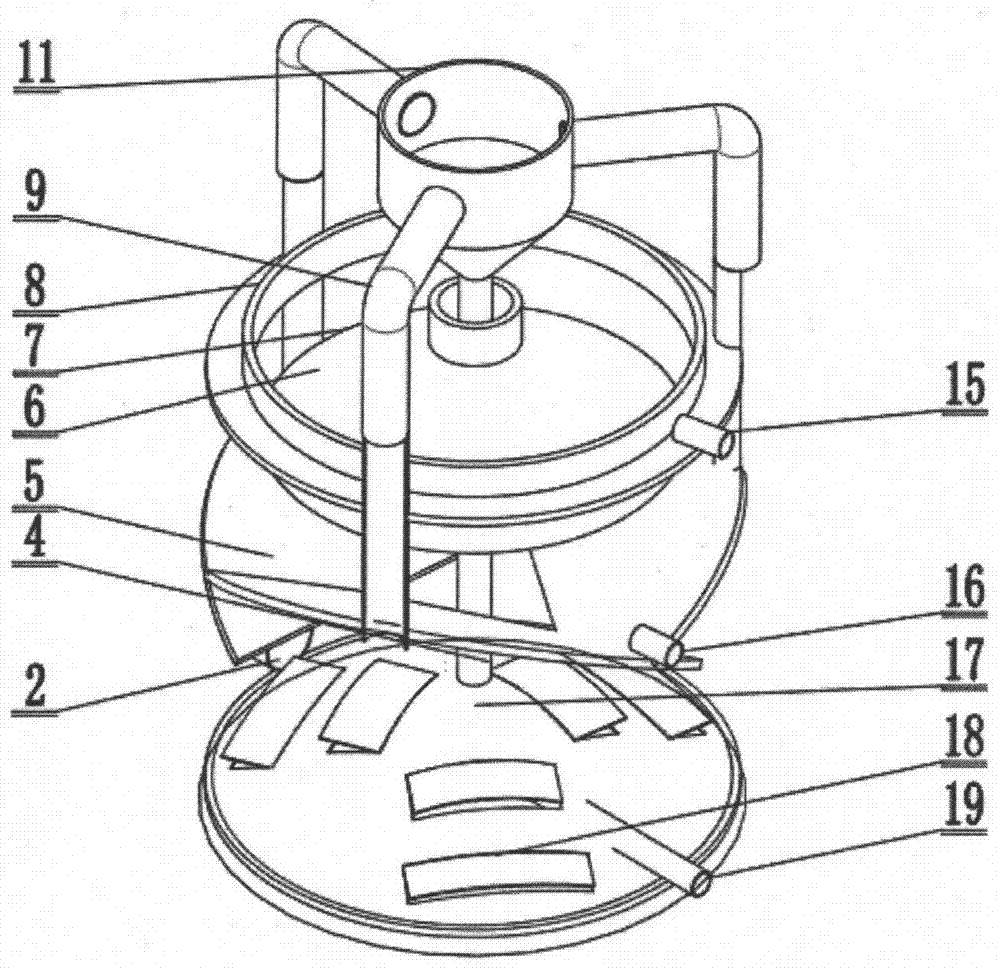

[0040] Figure 1 ~ Figure 3 Respectively, the three-dimensional view, the front section view and the three-dimensional schematic diagram of the internal structure of the internal circulation enhanced fully mixed flow anaerobic reactor provided in this embodiment, the internal circulation enhanced fully mixed flow anaerobic reactor is a short and fat type, and the main body is a cylindrical structure , from bottom to top, there are water distribution area I, full mixing area II, first separation area III and second separation area IV.

[0041] The water distribution area I is equipped with a bottom plate 1, an emptying port 2, a water inlet pipe 19, a hollow cone water distributor 17, an arc-shaped baffle 18 and the lower part of the cylindrical wall 3. The bottom of the cylindrical wall 3 is connected to the bottom plate 1, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com