Town sewage curing agent and preparation method thereof

A technology for urban sewage and polyferric chloride, which is applied in chemical instruments and methods, water pollutants, and other chemical processes, etc., can solve problems such as difficulty in obtaining purification standards for water bodies, unsolidified pollutants, and increasing organic components in water bodies. , to achieve the effect of reducing scaling and corrosion, reducing production costs and rapid precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Polyferric chloride 15kg, sodium aluminate 10kg, sodium carboxymethyl starch 3kg, sodium silicate 3kg, nano-montmorillonite 60kg, activated carbon 10kg, modified starch 60kg, sugar glycosides 3kg, alum 5kg, calcium chloride 3kg;

Embodiment 2

[0023] Polyferric chloride 20kg, sodium aluminate 15 parts kg, carboxymethyl starch sodium 4 parts kg, sodium silicate 4 kg, nano-montmorillonite 70 kg, activated carbon 15 parts kg, modified starch 70 kg, glycoside sugar 4 kg, alum 10 kg, Calcium chloride 4kg;

[0024] The method for preparing the above-mentioned Examples 1 and 2:

[0025] All the raw materials in the raw materials are put into the ball mill according to the ratio, mixed by the ball mill, and ground to a fineness of 350-450 meshes, and packed separately to obtain the microbial coagulant for urban sewage.

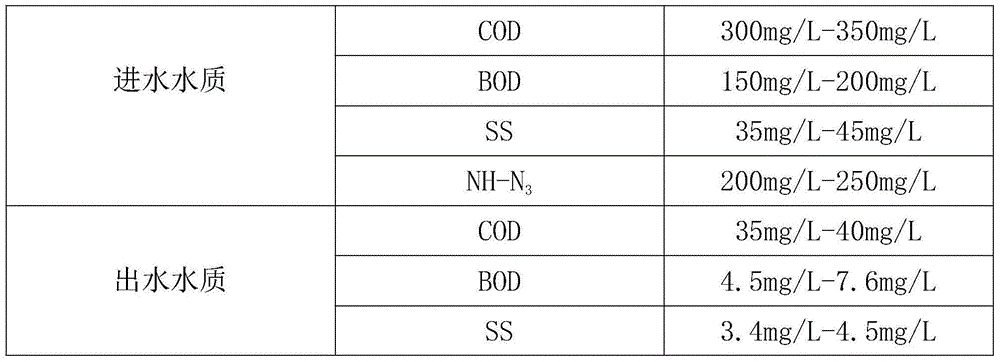

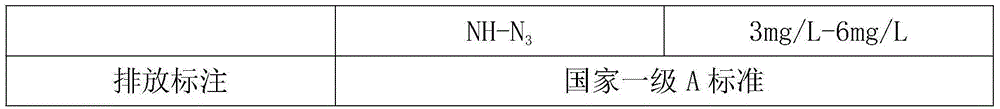

[0026] The following table is the experimental data obtained by carrying out the sewage treatment detection of this embodiment:

[0027]

[0028]

[0029] As can be seen from the table, the present invention can effectively remove SS, COD, BOD, organic matter and grease in the sewage by using the primary physical and chemical enhanced coagulation treatment agent in Examples 1 and 2. In addition, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com