A negative lead paste for power lead-acid battery and preparation method thereof

A technology of lead-acid battery and negative electrode paste, applied in lead-acid battery, battery electrode, circuit, etc., can solve the problems of short cycle life and achieve the effects of improved cycle life, low-temperature capacity, and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

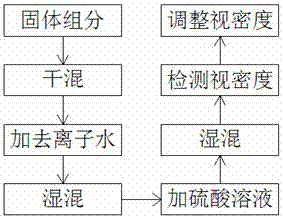

[0022] Such as figure 1 Shown is a schematic flow chart of a method for preparing the negative electrode paste of a power lead-acid battery according to the present invention. A kind of preparation method of power lead-acid storage battery negative lead paste of the present invention, comprises the following steps:

[0023] Step 1. Accurately weigh the following components by mass: 0.6 parts of synthetic fibers, 20 parts of barium sulfate, 0.5 parts of lignin, 1.5 parts of stannous sulfate, 1.5 parts of sodium lignosulfonate, and 15 parts of polyaniline; The synthetic fiber is a mixture of one or more of polyester fiber, polypropylene fiber and polyester fiber, and the length of the synthetic fiber is 2-4 mm.

[0024] Step 2. Preliminarily mix the components weighed in step 1, and then add them together to the paste mixer. Accurately weigh 1000 parts by mass of lead powder through the lead powder delivery pipeline and add it to the paste mixer. Turn on and Paste machine, dry...

specific Embodiment 2

[0030] Such as figure 1 Shown is a schematic flow chart of a method for preparing the negative electrode paste of a power lead-acid battery according to the present invention. A kind of preparation method of power lead-acid storage battery negative lead paste of the present invention, comprises the following steps:

[0031] Step 1. Accurately weigh the following components by mass: 0.9 parts of synthetic fibers, 30 parts of barium sulfate, 1.5 parts of lignin, 2 parts of stannous sulfate, 0.5 parts of sodium lignosulfonate, and 5 parts of polyaniline; The synthetic fiber is a mixture of one or more of polyester fiber, polypropylene fiber and polyester fiber, and the length of the synthetic fiber is 2-4 mm.

[0032] Step 2. Preliminarily mix the components weighed in step 1, and then add them together to the paste mixer. Accurately weigh 1000 parts by mass of lead powder through the lead powder delivery pipeline and add it to the paste mixer. Turn on and Paste machine, dry st...

specific Embodiment 3

[0038] Such as figure 1 Shown is a schematic flow chart of a method for preparing the negative electrode paste of a power lead-acid battery according to the present invention. A kind of preparation method of power lead-acid storage battery negative lead paste of the present invention, comprises the following steps:

[0039] Step 1. Accurately weigh the following components by mass: 0.8 parts of synthetic fibers, 10 parts of barium sulfate, 3 parts of lignin, 0.5 parts of stannous sulfate, 3 parts of sodium lignosulfonate, and 20 parts of polyaniline; The synthetic fiber is a mixture of one or more of polyester fiber, polypropylene fiber and polyester fiber, and the length of the synthetic fiber is 2-4 mm.

[0040] Step 2. Preliminarily mix the components weighed in step 1, and then add them together to the paste mixer. Accurately weigh 1000 parts by mass of lead powder through the lead powder delivery pipeline and add it to the paste mixer. Turn on and Paste machine, dry sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com