Coal combustion improver

A combustion-supporting agent and coal technology, applied in the field of coal-fired additives, can solve problems such as excessive nitrogen oxide emissions and air pollution, and achieve the effects of reducing environmental pollution, increasing gas production, and improving combustion-supporting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

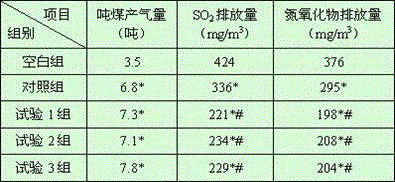

Image

Examples

Embodiment 1

[0026] Party:

[0027] Nano calcium oxide 20g, activated carbon 4g, chromium trioxide 2g, copper nitrate 8g,

[0028] Potassium nitrate 5g, cerium nitrate 4g, ferrocene 6g, diatomaceous earth 10g,

[0029] Ammonium bicarbonate 2g, diammonium phosphate 8g, polyoxyethylene castor oil 0.2g.

[0030] Preparation:

[0031] (1) Take activated carbon, chromium trioxide, copper nitrate, potassium nitrate, cerium nitrate, ferrocene and diatomaceous earth, grind them into fine powder, add deionized water, stir for 40 minutes, and get the mixed solution A;

[0032] (2) Take nano-calcium oxide, ammonium bicarbonate and diammonium phosphate, add deionized water, stir for 30 minutes, and get mixed solution B;

[0033] (3) Mix the above mixed solution A and mixed solution B, add polyoxyethylene castor oil, and make a water dispersant according to the conventional method.

[0034] The concentration of the resulting coal combustion improver is 60%.

Embodiment 2

[0036] Party:

[0037] Nano calcium oxide 20g, activated carbon 12g, chromium trioxide 10g, copper nitrate 16g,

[0038] Potassium nitrate 15g, cerium nitrate 10g, ferrocene 12g, diatomaceous earth 20g,

[0039] Ammonium bicarbonate 10g, diammonium phosphate 16g, polyoxyethylene castor oil 0.8g.

[0040] Preparation:

[0041] (1) Take activated carbon, chromium trioxide, copper nitrate, potassium nitrate, cerium nitrate, ferrocene and diatomaceous earth, grind them into fine powder, add deionized water, and stir for 60 minutes to obtain the mixed solution A;

[0042] (2) Take nano-calcium oxide, ammonium bicarbonate and diammonium phosphate, add deionized water, stir for 50 minutes, and get mixed solution B;

[0043] (3) Mix the above mixed solution A and mixed solution B, add polyoxyethylene castor oil, and make a water dispersant according to the conventional method.

[0044] The concentration of the resulting coal combustion improver is 80%.

Embodiment 3

[0046] Party:

[0047] Nano calcium oxide 20g, activated carbon 8g, chromium trioxide 6g, copper nitrate 12g,

[0048] Potassium nitrate 10g, cerium nitrate 7g, ferrocene 9g, diatomaceous earth 15g,

[0049] Ammonium bicarbonate 6g, diammonium phosphate 12g, polyoxyethylene castor oil 0.5g.

[0050] Preparation:

[0051] (1) Take activated carbon, chromium trioxide, copper nitrate, potassium nitrate, cerium nitrate, ferrocene and diatomaceous earth, grind them into fine powder, add deionized water, and stir for 50 minutes to obtain the mixed solution A;

[0052] (2) Take nano-calcium oxide, ammonium bicarbonate and diammonium phosphate, add deionized water, stir for 40 minutes, and get mixed solution B;

[0053] (3) Mix the above mixed solution A and mixed solution B, add polyoxyethylene castor oil, and make a water dispersant according to the conventional method.

[0054] The concentration of the resulting coal combustion improver is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com