Corrosion and scale inhibitor applicable to circulating cooling water high in chlorine content and bromine content

A technology of corrosion and scale inhibitor and circulating cooling water, applied in the field of water treatment, can solve the problems of good scale inhibition effect, slow release or poor scale inhibition effect of copper material, material limitation, etc., to achieve good corrosion and scale inhibition performance, Good corrosion and scale inhibition effect and small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Corrosion and scale inhibitor suitable for high chlorine and high bromine circulating cooling water, the raw material components are as follows, all in parts by weight:

[0057] Hydroxyethylidene diphosphonic acid (HEDP) 5.4 parts

[0058] 1.5 parts of hydrolyzed polymaleic anhydride (HPMA)

[0059]Acrylic acid-2-acrylamido-2-methylpropanesulfonic acid copolymer (AA-AMPS) 0.5 parts

[0060] Zinc sulfate (ZnSO 4 )1.2 parts

[0061] Benzotriazole (BTA) 1.2 parts

[0062] The corrosion and scale inhibitor of this embodiment is added to the circulating water shown in Table 1, and the dosage is 10ppm,

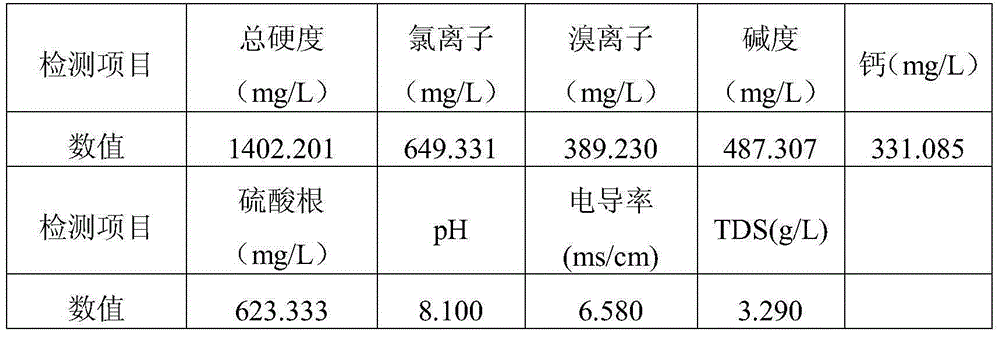

[0063] Table 1 Circulating water test index

[0064]

[0065] After adding the corrosion and scale inhibitor of this example, the scale inhibition effect and the slow release effect on carbon steel, stainless steel and brass were tested, so that the corrosion rate of carbon steel was reduced to 0.0104mm / year, and the corrosion rate of stainless steel was reduced to 0....

Embodiment 2

[0067] Corrosion and scale inhibitor suitable for high chlorine and high bromine circulating cooling water, the raw material components are as follows, all in parts by weight:

[0068] Hydroxyethylidene diphosphonic acid (HEDP) 5.2 parts

[0069] Hydrolyzed polymaleic anhydride (HPMA) 1.3 parts

[0070] Acrylic acid-2-acrylamido-2-methylpropanesulfonic acid copolymer (AA-AMPS) 0.5 parts

[0071] Zinc sulfate (ZnSO 4 ) 1 copy

[0072] Benzotriazole (BTA) 2 parts.

[0073] The corrosion and scale inhibitor of this embodiment is added to the circulating water shown in table 2, and the dosage is 15ppm,

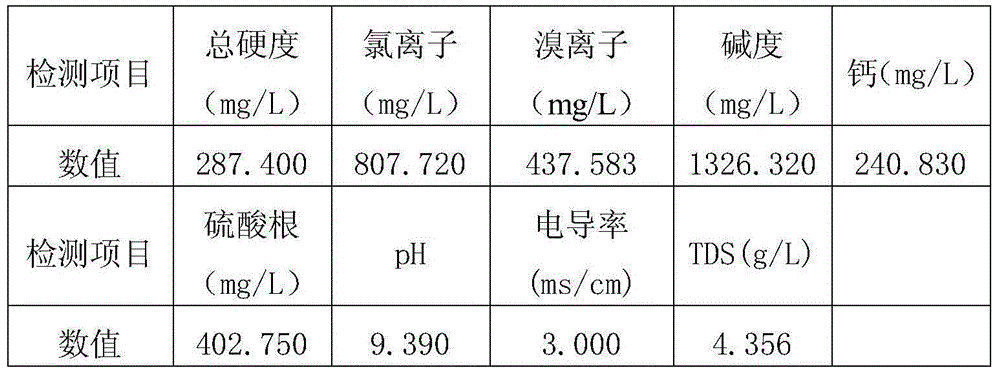

[0074] Table 2 Circulating water test index

[0075]

[0076] After adding the corrosion and scale inhibitor of this embodiment, the scale inhibition effect and the slow release effect on carbon steel, stainless steel and brass were tested, so that the corrosion rate of carbon steel was reduced to 0.0087mm / year, and the corrosion rate of stainless steel was reduced to 0.00...

Embodiment 3

[0078] Corrosion and scale inhibitor suitable for high chlorine and high bromine circulating cooling water, the raw material components are as follows, all in parts by weight:

[0079] 6 parts of hydroxyethylidene diphosphonic acid (HEDP)

[0080] 1.7 parts of hydrolyzed polymaleic anhydride (HPMA)

[0081] Acrylic acid-2-acrylamido-2-methylpropanesulfonic acid copolymer (AA-AMPS) 0.7 parts

[0082] Zinc sulfate (ZnSO 4 ) 1 copy

[0083] Benzotriazole (BTA) 2 parts.

[0084] Add the corrosion and scale inhibitor of this embodiment into the circulating water shown in table 3, and the dosage is 15ppm,

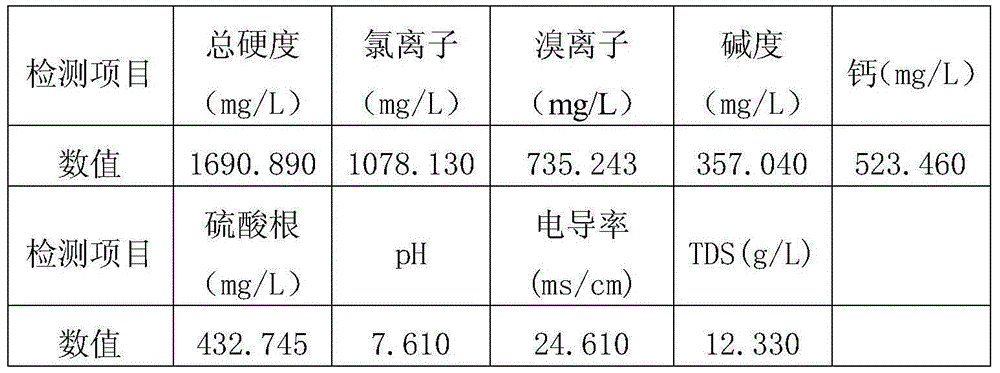

[0085] Table 3 Circulating water test index

[0086]

[0087] After adding the corrosion and scale inhibitor of this example, the scale inhibition effect and the slow release effect on carbon steel, stainless steel and brass were tested, so that the corrosion rate of carbon steel was reduced to 0.0072mm / year, and the corrosion rate of stainless steel was reduced to 0.0040...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com