Method for treating trivalent arsenic in water by photooxidation of small molecule diketone

A technology for oxidation treatment and trivalent arsenic, applied in the direction of oxidation water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of destroying chromophore, slow oxygen oxidation rate, and toxic by-products of chlorine gas and other problems, to achieve the effect of wide pH range and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

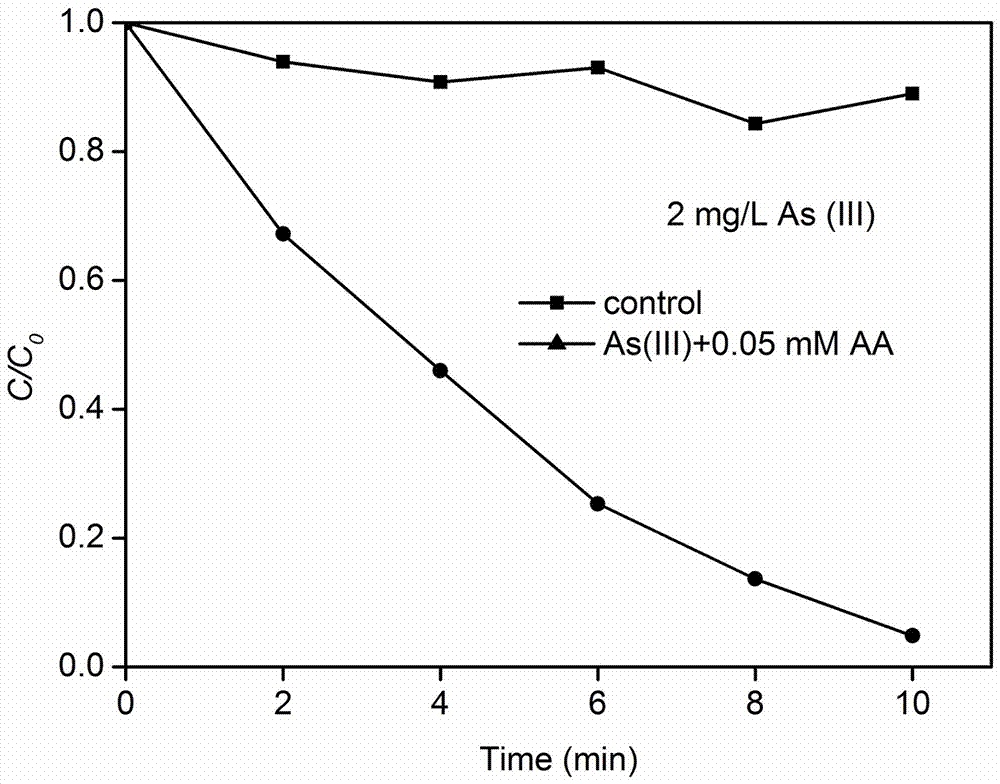

[0032] (1) UV / AA oxidation effect

[0033] Add Na to a 25mL colorimetric tube 3 AsO 3 Stock solution and AA solution, add the As(III) stock solution of 1g / L (unit is with Na 3 AsO 3 In terms of As(III), 3.468 g Na 3 AsO 3Dissolved in 1 L of water, the concentrations mentioned below are calculated as As(III)) and diluted step by step to As(III) concentration of 2 mg / L and AA concentration of 0.05 mM; then poured into 25 mL reaction In the tube, the photochemical oxidation reaction was carried out for 10 minutes, and the As(III) concentration was detected by sampling every 2 minutes; at the same time, a control experiment (control) was set up without AA (As(III) concentration was 2 mg / L);

[0034] figure 1 It is a schematic diagram of the concentration change of As(III) in the reaction solution in 10 minutes. In the figure, the abscissa is the time (min), and the ordinate is the real-time As(III) concentration (C) and the initial As(III) concentration (C 0 ) ratio, by fi...

Embodiment 2

[0056] Utilize Na 3 AsO 3 The stock solution and AA solution were diluted step by step in a 25 mL colorimetric tube. After dilution, the concentration of As(III) was 5 mg / L, and the concentration of AA was 0.1 mM, and then the solution was poured into the photoreaction tube for photochemical oxidation reaction For 20 min, samples were taken every 10 min to detect the concentration of As(III), and at the same time, Na 3 AsO 3 Solution (As(III) concentration is 5 mg / L) was used as control.

[0057] According to the final result, such as Figure 6 shown by Figure 6It can be seen that compared with the control group, after adding AA, the oxidation rate of As(III) is very fast, basically within 10 min, the oxidation reaction of As(III) has completely occurred to form As(V).

Embodiment 3

[0059] Utilize Na 3 AsO 3 The stock solution and AA solution were diluted step by step in a 25mL colorimetric tube. After dilution, the concentration of As(III) was 20 mg / L, and the concentration of AA was 0.5 mM. Then the solution was poured into the photoreaction tube for photochemical oxidation reaction 60 min, samples were taken every 10 min to detect As(III) concentration, and Na 3 AsO 3 Solution (As(III) concentration of 20 mg / L) was used as control.

[0060] Test results such as Figure 7 As shown, compared with the control group, after the addition of AA, 20 mg / L of As(III) could be completely oxidized within 60 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com