Compound visible photocatalyst, and preparation method and application thereof

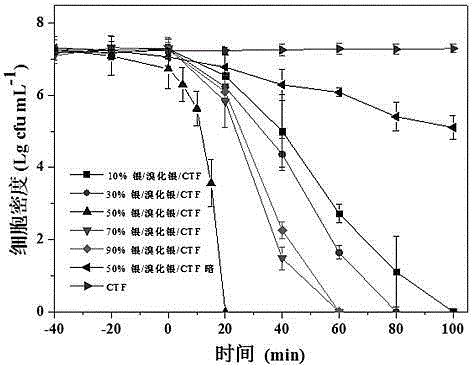

A catalyst and visible light technology, which is applied in the field of composite visible light catalyst and its preparation, can solve the problems of low photocatalytic performance, low quantum efficiency, and research on bactericidal performance of CTF, and achieve good application prospects and high-efficiency bactericidal performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The specific preparation method of the composite visible light catalyst of the present invention comprises the following steps:

[0024] (1) Preparation of covalent triazine polymer

[0025] Under the condition of stirring at 0°C, add 40mL trifluoromethanesulfonic acid into 5.12g terephthalonitrile, change the oil bath and raise the temperature to 30°C, after standing for 3 days, the obtained solid is rinsed with 160-200mL of dichloromethane , and then washed with ammonia water; then add 200-250mL ammonia water and stir overnight, wash with water and centrifuge, and finally wash with methanol and centrifuge once to obtain a solid precipitate; reflux the solid with methanol at 90°C for 36h, then dichloromethane in Reflux at 70°C for 36 hours, and vacuum dry at 80°C for 12 hours to obtain a covalent triazine polymer;

[0026] (2) Preparation of AgBr / CTF complex

[0027] Add 0.169-1.518g of hexadecyltrimethylammonium bromide into 50mL of distilled water, heat and dissolv...

Embodiment 1

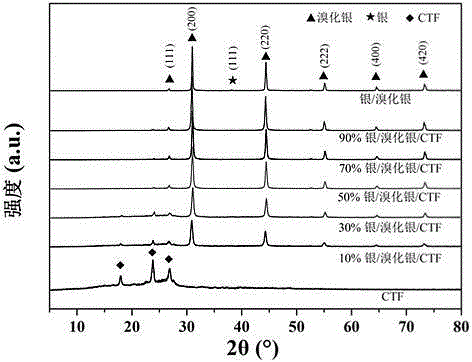

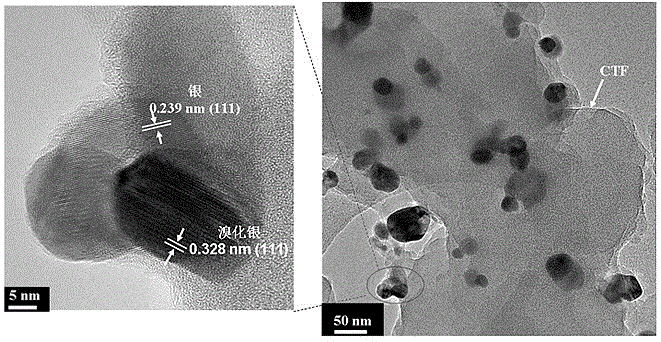

[0032] The preparation of embodiment 1Ag / AgBr / CTF composite

[0033] Add 0.169g of cetyltrimethylammonium bromide into a beaker with 50mL of distilled water, heat and dissolve in a water bath at 70°C, add 0.5g of the prepared CTF, stir and dissolve for 60min, then add 0.079g of AgNO 3 , continue to stir for 4 hours, then centrifuge, wash the precipitate with distilled water and absolute ethanol, and dry it at 80°C to obtain an AgBr / CTF composite with a loading capacity of AgBr of 10%; In a quartz tube, stir and pass hydrogen for 30 minutes, irradiate for 2 hours under a 400nm xenon lamp, centrifuge, dry, and grind to obtain the Ag / AgBr / CTF composite with a loading of Ag element of 10%.

Embodiment 2

[0034] The preparation of embodiment 2Ag / AgBr / CTF composite

[0035] Add 0.506g of cetyltrimethylammonium bromide into a beaker filled with 50mL of distilled water, heat and dissolve in a water bath at 70°C, add 0.5g of the prepared CTF, stir and dissolve for 60min, then add 0.236g of AgNO 3 , continue to stir for 4 hours, then centrifuge, wash the precipitate with distilled water and absolute ethanol, and dry it at 80°C to obtain an AgBr / CTF composite with a loading capacity of AgBr of 30%; In a quartz tube, after stirring and passing hydrogen for 30 minutes, irradiate for 2 hours under a 400nm xenon lamp, centrifuge, dry, and grind to obtain an Ag / AgBr / CTF composite with an Ag element loading of 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com