Flexible attapulgite membrane and preparation method thereof

A technology of attapulgite and flexibility is applied in the field of attapulgite membrane and its preparation, which can solve the problem of inflexibility of membrane materials, and achieve the effects of obvious flexibility, uniform texture and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) At room temperature, weigh 20 g of attapulgite and disperse it in 400 mL of deionized water, add 20 mL of 1M HCl solution, stir vigorously with a mechanical stirrer for 12 hours, then filter to remove large particles and impurities, and centrifuge to obtain acidified attapulgite. Then wash the acidified attapulgite with deionized water, then disperse it in deionized water, centrifuge and wash repeatedly until the filtrate is neutral.

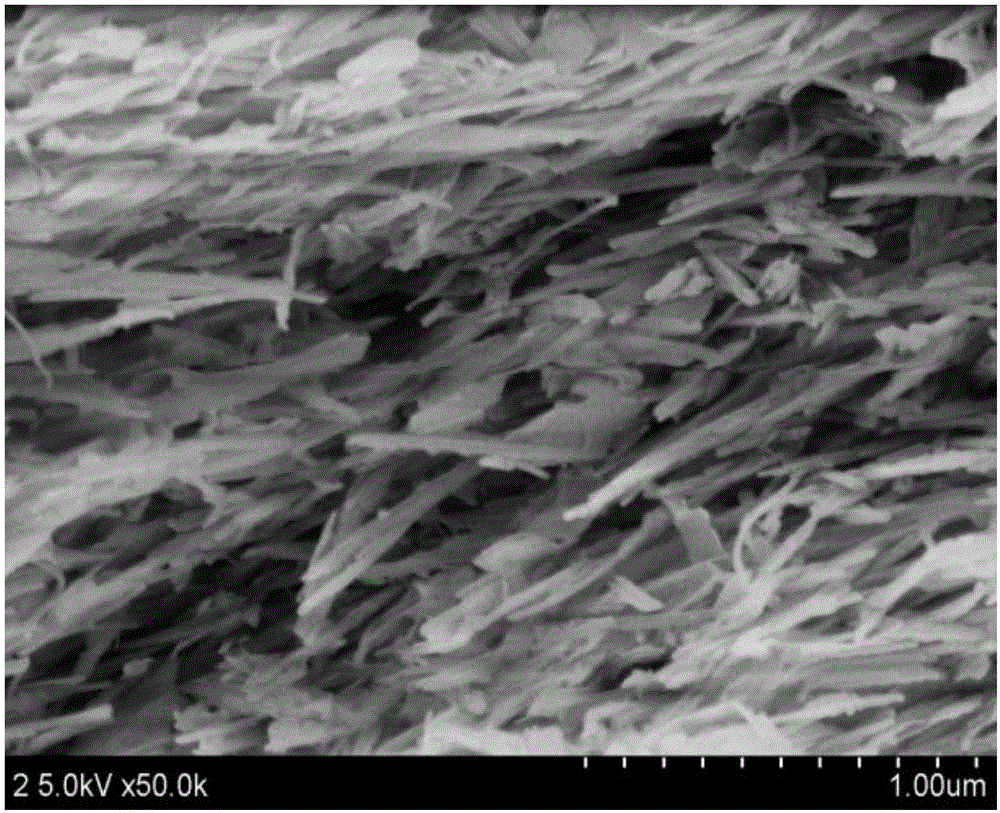

[0031] (2) Dry the attapulgite in step (1) in a blower dryer at 100° C., grind it into powder, and pass through a 100-mesh sieve to obtain purified attapulgite. Disperse 2 g of the purified attapulgite in 400 mL of deionized water, ultrasonically disperse it in an ultrasonic cleaner for 180 min, and separate the stable floc in the upper layer to obtain the attapulgite suspension.

[0032] (3) Concentrate the attapulgite suspension in step (2) until viscous in a blast dryer at 60°C. Measure a known volume of the suspension, dry it in ...

Embodiment 2

[0037] Steps (1), (2), (3) are the same as steps (1), (2), (3) of Example 1.

[0038] (4) Dissolve 0.56g of cornstarch in 50g of deionized water, heat and stir in a water bath at 60°C for 8 hours until completely dissolved, and take 5mL of starch solution at a speed of 0.5mL / min at the speed of a magnetic stirrer at 800r / min Add dropwise to 45mL of the attapulgite suspension in step 3 (attapulgite: corn starch mass ratio is about 100:4), after the dropwise addition, reduce the speed of the magnetic stirrer to 200r / min, and stir for 8h.

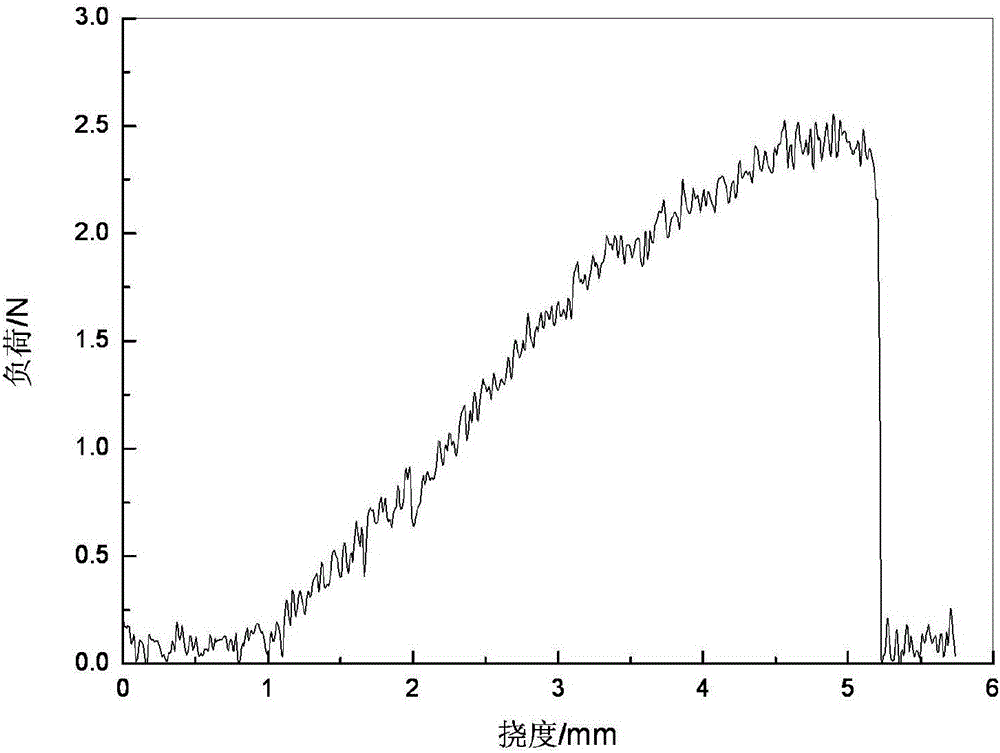

[0039] (5) Take 30 mL of the suspension obtained in step (4) and place it in a plastic petri dish with a diameter of 50 mm, and evaporate water at a constant temperature in a vacuum oven at 60° C. to obtain a flexible attapulgite film. The attapulgite membrane was subjected to a three-point bending mechanical test. The circular attapulgite membrane with a diameter of 48.5mm and a thickness of 0.6mm can withstand a load of 1.71N, with a deflect...

Embodiment 3

[0041] (1) At room temperature, weigh 25g of attapulgite and disperse it in 500mL of deionized water, and add 10mL of 0.5MH 2 SO 4 Solution, stirred vigorously with a mechanical stirrer for 12 hours, then filtered to remove large particles and impurities, centrifuged to obtain acidified attapulgite, then washed the acidified attapulgite with deionized water, then dispersed it in deionized water, centrifuged, Washing is repeated several times until the filtrate is neutral.

[0042] Steps (2), (3) and (5) are the same as steps (2), (3) and (5) of Example 1, wherein the mass concentration of the attapulgite suspension is 2.03%

[0043] (4) Dissolve 3g of polyvinyl alcohol in 97g of deionized water, heat and stir in an oil bath at 90°C for 6 hours until completely dissolved, and take 1mL of polyvinyl alcohol solution at a speed of 800r / min with a magnetic stirrer at 0.5mL / Add it dropwise to 49mL of the attapulgite suspension in step 3 (the mass ratio of attapulgite to polyvinyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com