Method for preparing uneven particle layer, organic light-emitting device, and display device

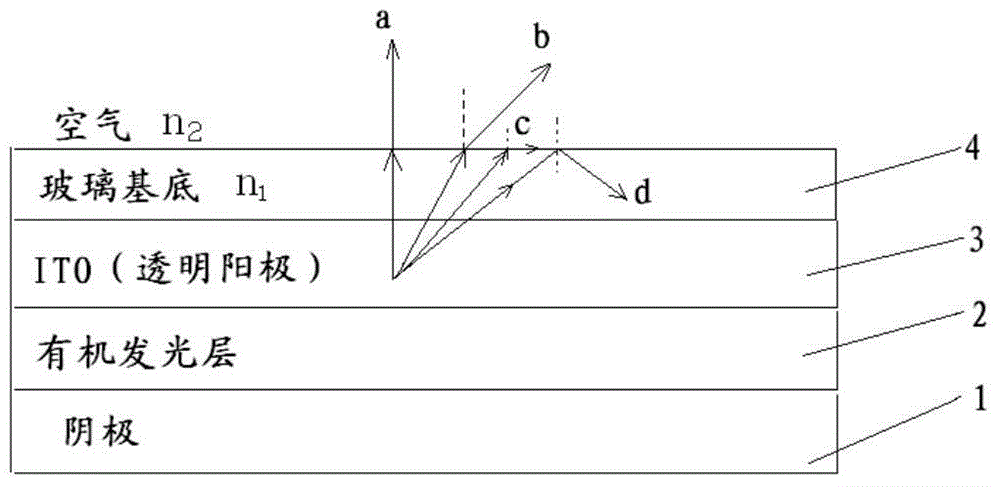

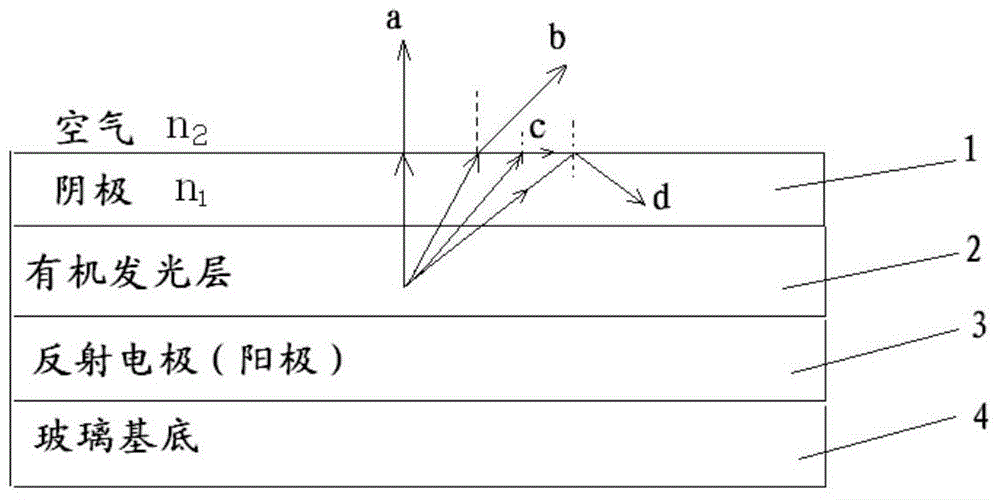

A particle layer, electroluminescence technology, applied in the direction of organic semiconductor devices, electric solid devices, optical components, etc., can solve the problem of low light extraction efficiency, and achieve improved light extraction efficiency, stable device performance, improved brightness and viewing angle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

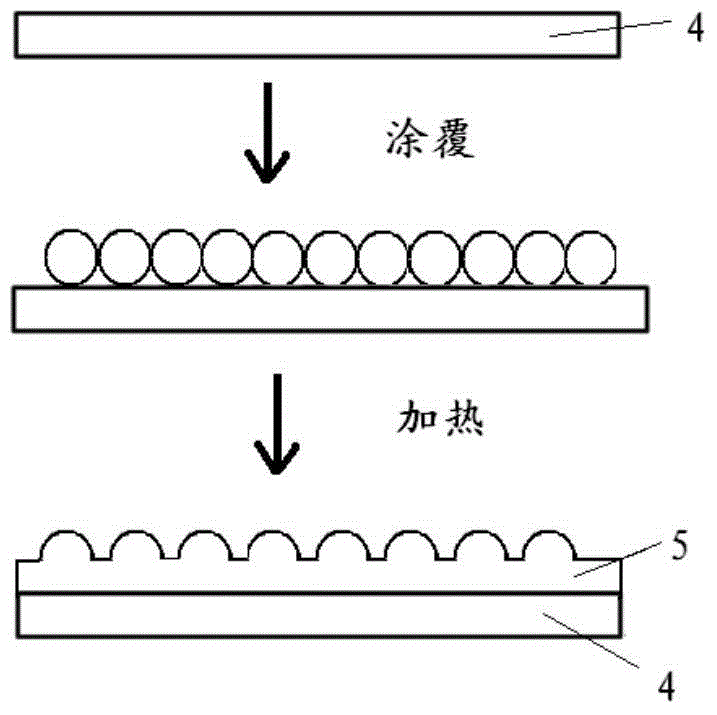

[0032] This embodiment provides a method for preparing an uneven particle layer, comprising the following steps:

[0033] forming a layer of nanoparticles on the substrate;

[0034] heating the substrate so that the nanoparticles in contact with the substrate melt while the nanoparticles on the surface are in a solid state;

[0035] Cooling the above substrate forms a nanoparticle layer with an uneven surface.

[0036] The preparation method of the uneven particle layer in this embodiment only needs to add coating and heating steps, and the method is simple and easy for industrial production. The surface unevenness of the uneven particle layer prepared by this method is uniform and periodic. The substrate comprising the nanoparticle layer is used in an OLED device, the performance of the device is stable, and the propagation direction of the light of the organic light-emitting layer of the OLED device can be changed to avoid the formation of total internal reflection at the i...

Embodiment 2

[0038] This embodiment provides a method for preparing an uneven particle layer, such as image 3 shown, including the following steps:

[0039] S1, forming a nanoparticle layer on the substrate;

[0040] Mixing the nanoparticles with the solvent and dispersant of the nanoparticles to form a mixed liquid of the nanoparticles; that is, mixing the nanoparticles with the solvent and the dispersant, wherein the dispersant helps to promote the discharge of the nanoparticles on the surface of the substrate 4 Cloth, prevents the accumulation of nanoparticles and helps to form a monolayer of nanoparticles.

[0041] Preferably, the nanoparticles are spherical in shape.

[0042] Wherein, when the shape of the nanoparticles is spherical, the degree of surface unevenness of the formed uneven particle layer 5 is uniform and the periodicity is good. When it is used in an OLED device, the light will not undergo total internal reflection on the spherical surface, and the direction of light...

Embodiment 3

[0064] This embodiment provides an organic electroluminescent device, such as Figure 4 As shown, it includes a substrate 4 , an anode 3 , an organic light-emitting layer 2 and a cathode 1 ; the substrate 4 is the substrate 4 prepared by the method of the above-mentioned embodiment 2 and includes an uneven particle layer.

[0065] In this embodiment, a specific OLED device A is given:

[0066] Wherein, the nanoparticles are polystyrene nanoparticles with a particle diameter of 600nm, the solvent is methanol, and the dispersant is PVP.

[0067] The substrate 4 is made of PET (polyethylene terephthalate), the material of the anode 3 is aluminum, and the thickness of the anode 3 is 150 nm.

[0068] Concrete preparation steps include:

[0069] Add polystyrene nanoparticles with a particle size of 600nm and dispersant PVP into the solvent methanol and mix evenly to form a mixed solution;

[0070] Coating the above mixed solution on the PET substrate 4;

[0071] Heating the side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com