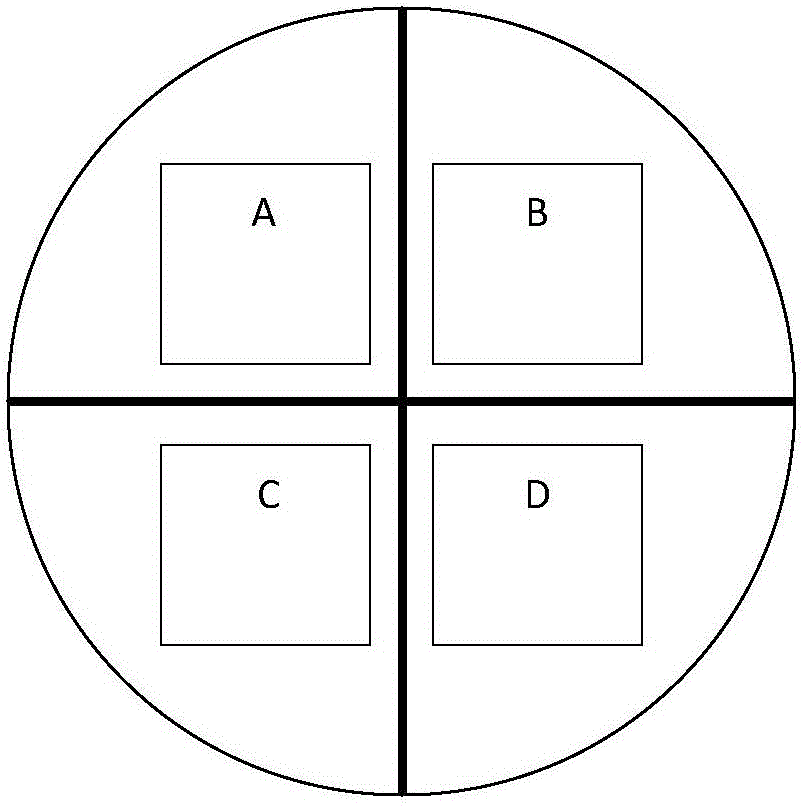

An Si-PIN four-quadrant photoelectric detector based on MEMS microstructure silicon and a manufacturing method thereof

A photodetector and microstructure technology, applied in the field of photoelectric detection, can solve the problem of inability to achieve precise positioning and target detection at the same time, and achieve the effect of widening the spectral response range, low cost and high responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

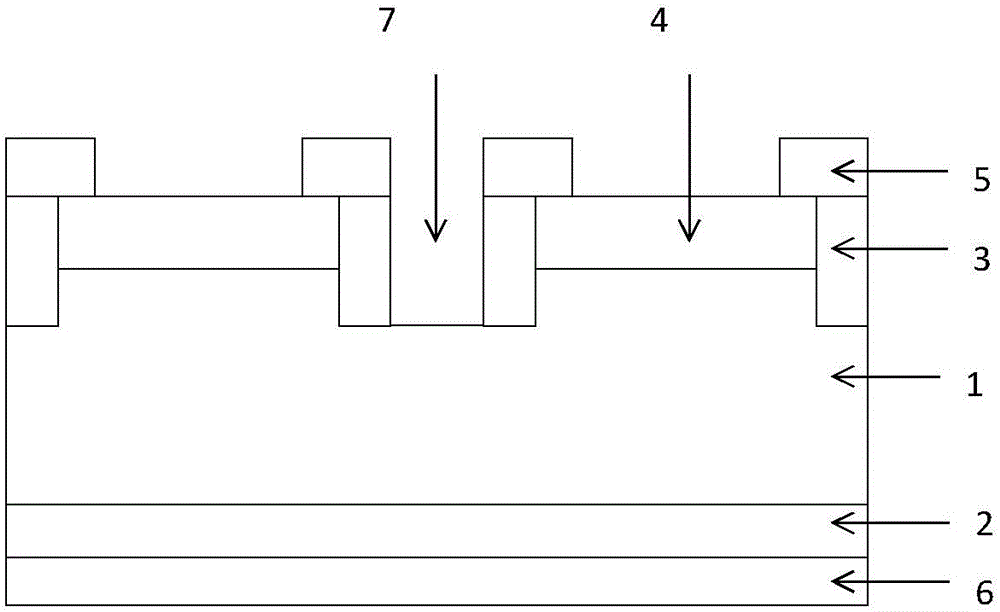

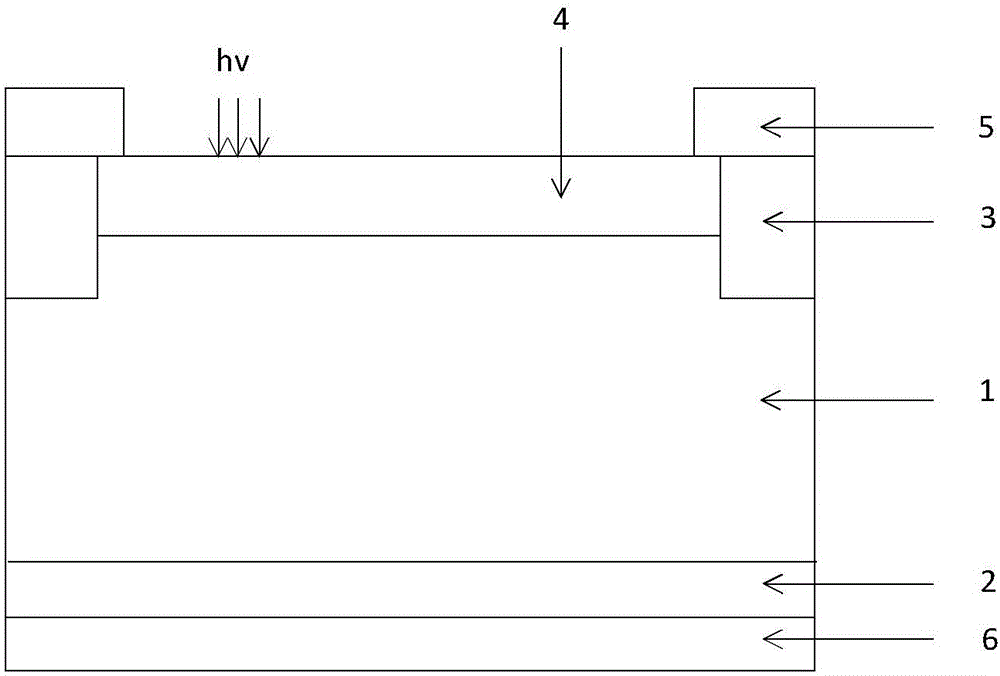

[0039] A Si-PIN four-quadrant photodetector based on MEMS microstructure silicon, including 4 unit photodetectors with identical performance located in different quadrants in Cartesian coordinates, characterized in that: the unit photodetectors are packaged sequentially from bottom to top The lower electrode 6, the N-type MEMS microstructure silicon layer 2, the silicon intrinsic substrate 1, the silicon intrinsic substrate 1 is provided with a P-type region 4, and an annular P + region 3, also includes a P-type region 4, and P + For the upper electrode 5 on the upper surface of the area 3, the surface of the MEMS microstructured silicon layer is columns or holes arranged in an array, with a diameter of 2 μm, a height or depth of 1 μm, and a period of 2 μm. Doping S or Te elements on MEMS microstructure silicon, ion implantation doping concentration range is 1×10 14 ion / cm 2 . The ring P + Region 3 is doped with boron B, and its doping concentration range is 1×10 18 ion / c...

Embodiment 2

[0041] A Si-PIN four-quadrant photodetector based on MEMS microstructure silicon, including four unit photodetectors with the same performance located in different quadrants in Cartesian coordinates, and the unit photodetectors are arranged sequentially from bottom to top. Electrode 6, N-type MEMS microstructure silicon layer 2, silicon intrinsic substrate 1, on which silicon intrinsic substrate 1 is provided with P-type region 4, and annular P + region 3, also includes a P-type region 4, and P + The upper electrode 5 on the upper surface of the region 3 . The surface of the MEMS microstructured silicon layer is columns or holes arranged in an array, with a diameter of 3 μm, a height or depth of 2 μm, and a period of 3 μm. Doping S or Te elements on MEMS microstructure silicon, ion implantation doping concentration range is 1×10 16 ion / cm 2 . The ring P + Region 3 is doped with boron B, and its doping concentration range is 5×10 19 ion / cm 3 . The upper end electrode 5 ...

Embodiment 3

[0043] A method for preparing a Si-PIN four-quadrant detector based on MEMS microstructure silicon, the steps are as follows:

[0044] Step 1: Prepare a silicon single wafer substrate material with a clean and dry surface, a high-resistance resistivity of 1000Ω·cm-2000Ω·cm, and a crystal orientation of , and oxidize and grow SiO on the surface of the silicon substrate 1 2 film layer.

[0045] Step 2: On SiO 2 Two quadrant isolation grooves are photoetched on the film layer along two orthogonal diameter directions, the groove width is 100 μm, and the groove depth is 3 μm.

[0046] Step 3: SiO in each quadrant 2 Synchronous photoetching of P around the surface of the film + The pattern of area 3, and then perform boron B heavy diffusion doping to form P + Zone 3, the doping concentration range is 1×10 18 ion / cm 3 .

[0047] Step 4: SiO in each quadrant 2 The pattern of the P-type region 4 is synchronously photoetched on the surface of the film layer, and then boron B is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com