High-performance ceramic ball valve

A ceramic ball valve, high-performance technology, applied to valve devices, cocks including cut-off devices, engine components, etc. The effect of avoiding safety hazards and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

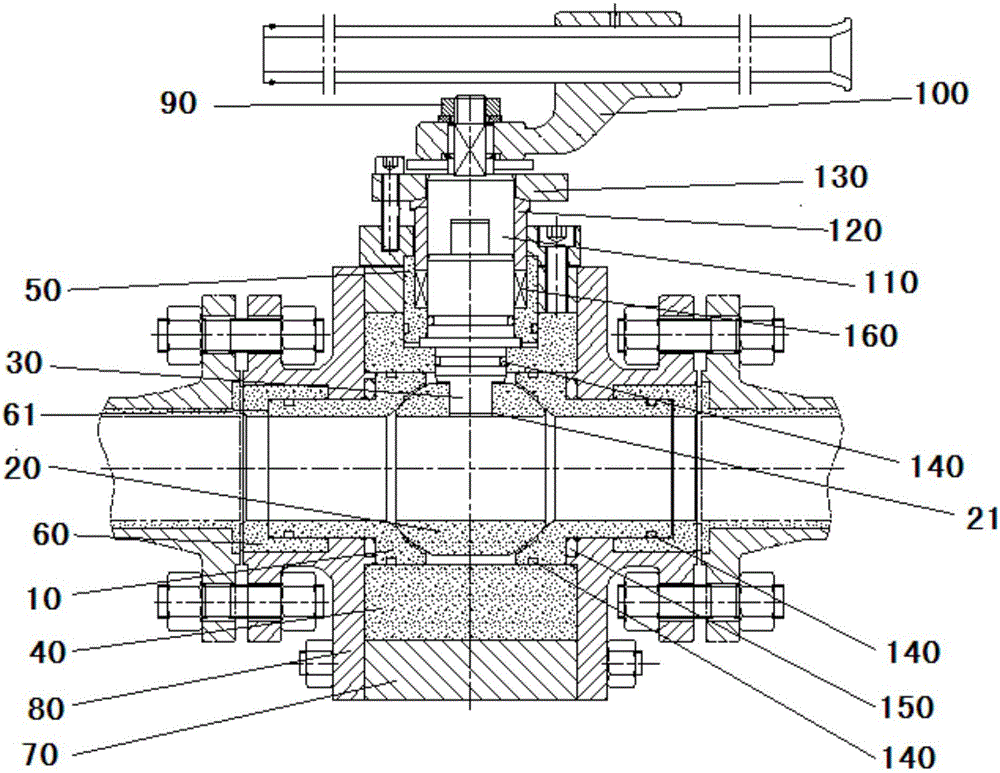

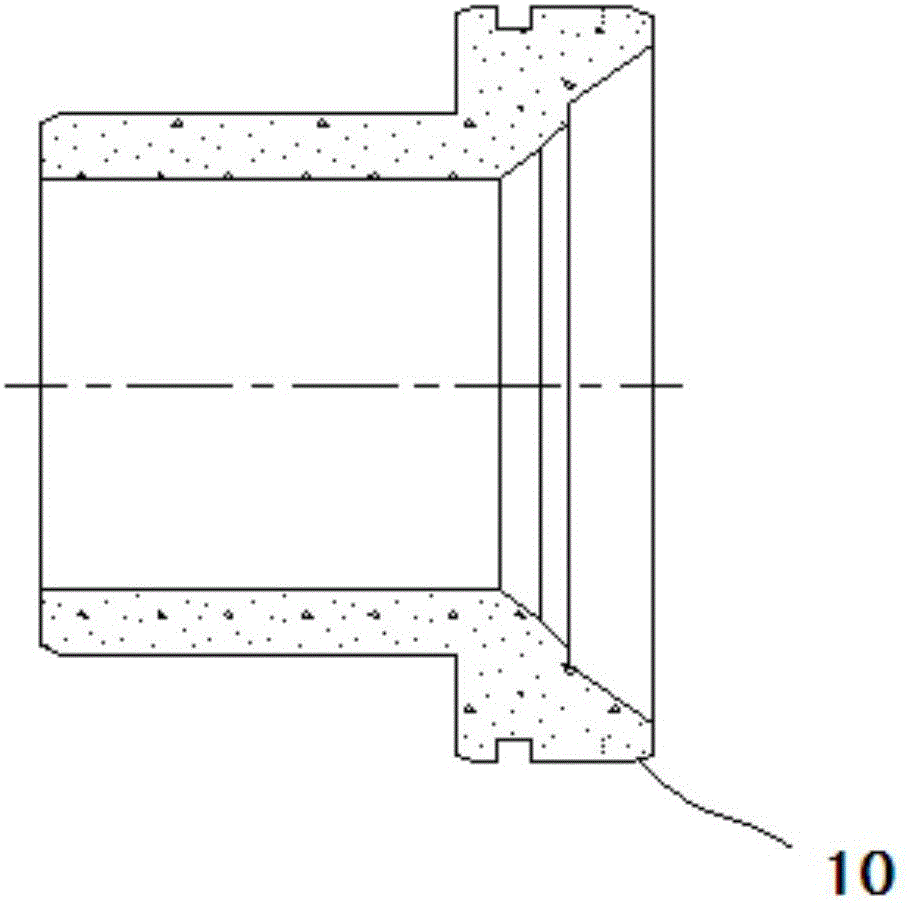

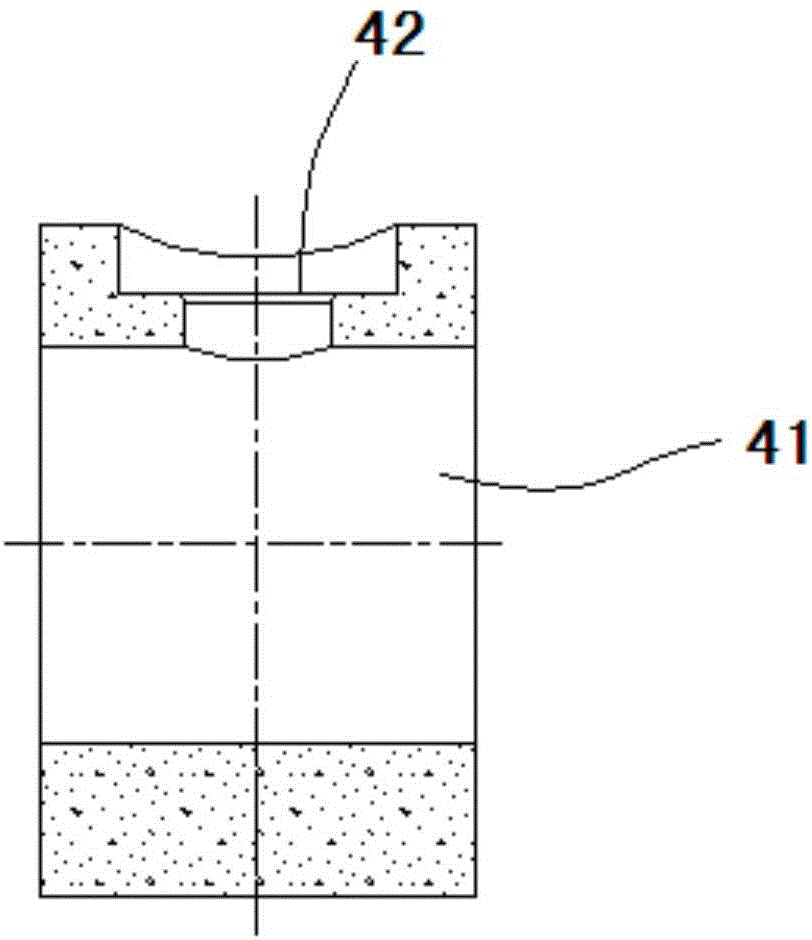

[0022] see Figure 1 to Figure 3 As shown, the present invention discloses a high-performance ceramic ball valve. The ceramic ball valve includes a valve seat 10 made of ceramics, a ball 20, a valve stem 30, a valve body bush 40, a stuffing box 50, a valve seat bush 60 and a metal material. The finished valve body 70, valve cover 80, fastener 90, handle seat 100, drive shaft 110, packing gland 120, packing pressure plate 130; the valve seat bushing 60 is provided with a stepped inner hole 61, and the stepped inner hole The outer diameter is connected with the inner hole of the valve cover 80, and the inner diameter of the stepped inner hole is connected with the outer circle of the tail of the valve seat 10. The joint is provided with multiple e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com