Gold finger manufacturing method and gold finger

A manufacturing method and gold finger technology, which is applied in the direction of printed circuit manufacturing, electrical connection printed components, printed circuit components, etc., can solve short circuit, lifting and laying on the nearby gold finger 2′, nickel-gold layer hanging nickel And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

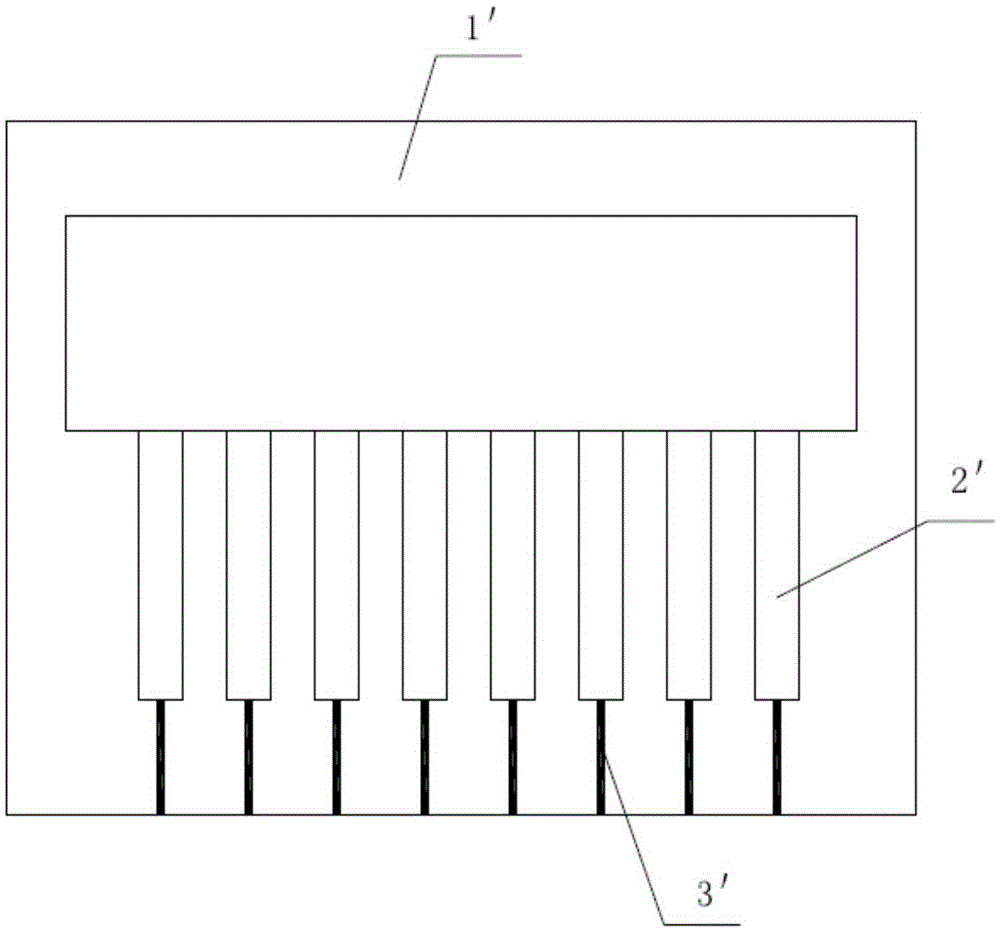

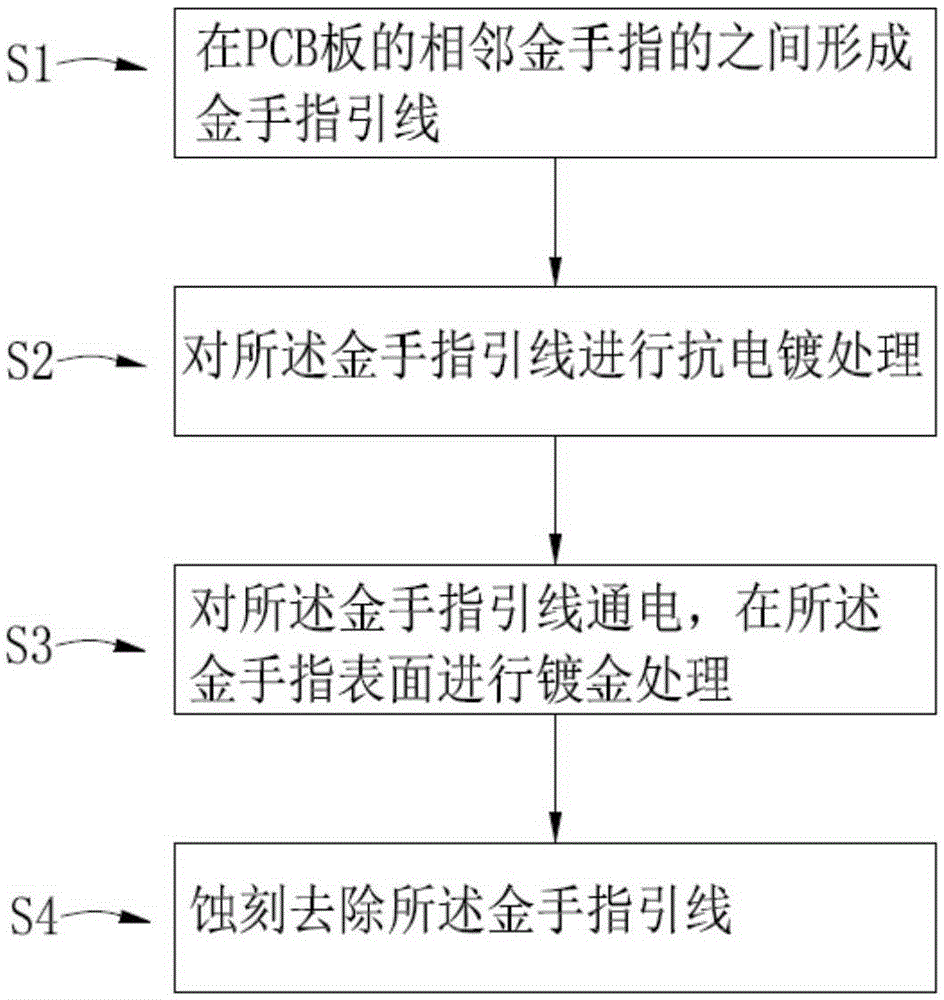

[0040] Such as image 3 As shown, the manufacturing method of a golden finger provided in this embodiment mainly includes the following steps:

[0041] S1: A gold finger lead 3 is formed between adjacent gold fingers 2 on the PCB, wherein the gold finger lead is connected between the root areas of adjacent gold fingers, such as Figure 4 shown;

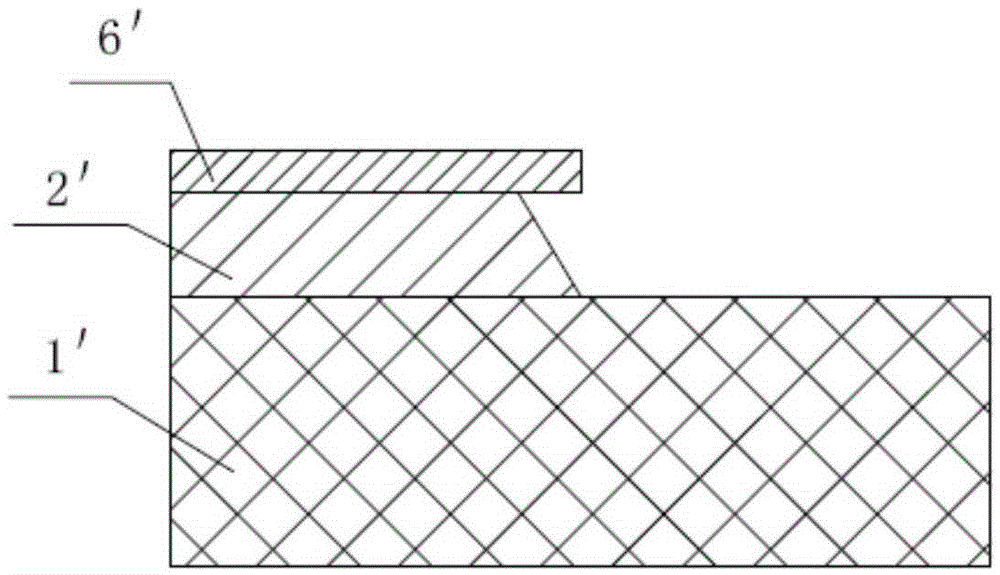

[0042] S2: Perform anti-plating treatment on the gold finger guide wire 3, such as Figure 5 shown;

[0043] S3: energize the gold finger lead 3, and perform gold plating on the surface of the gold finger 2;

[0044] S4: Etching and removing the gold finger wire 3 .

[0045] It should be noted that the root area of the gold finger refers to the area away from the end (ie, the free end, the end for plugging) of the gold finger.

[0046]In the manufacturing method of the above gold finger, the gold finger guide line 3 is arranged between the sides of the adjacent gold finger 2, and when the gold finger guide line 3 is etched afte...

Embodiment 2

[0054] This embodiment provides a gold finger, which is prepared by any one of the manufacturing methods described in Embodiment 1.

[0055] Since the nickel-gold layer 6 is still electroplated on the end of the above-mentioned gold finger and there is no hanging nickel phenomenon, when the client is plugged and used, the nickel-gold layer 6 at the end of the gold finger is prevented from being tilted to the adjacent gold finger. cause a short circuit. Therefore, the stability of the structure and function of the product is guaranteed when it is used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com